Driving device of automatic tool changer

A technology of automatic tool changer and driving device, which is applied in the direction of positioning device, metal processing machine parts, clamping, etc., and can solve the problems that the operator is difficult to maintain the motor, and lead to the front side of the fixed frame, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] Hereinafter, an example of the embodiment of the present invention will be described in detail with reference to the drawings.

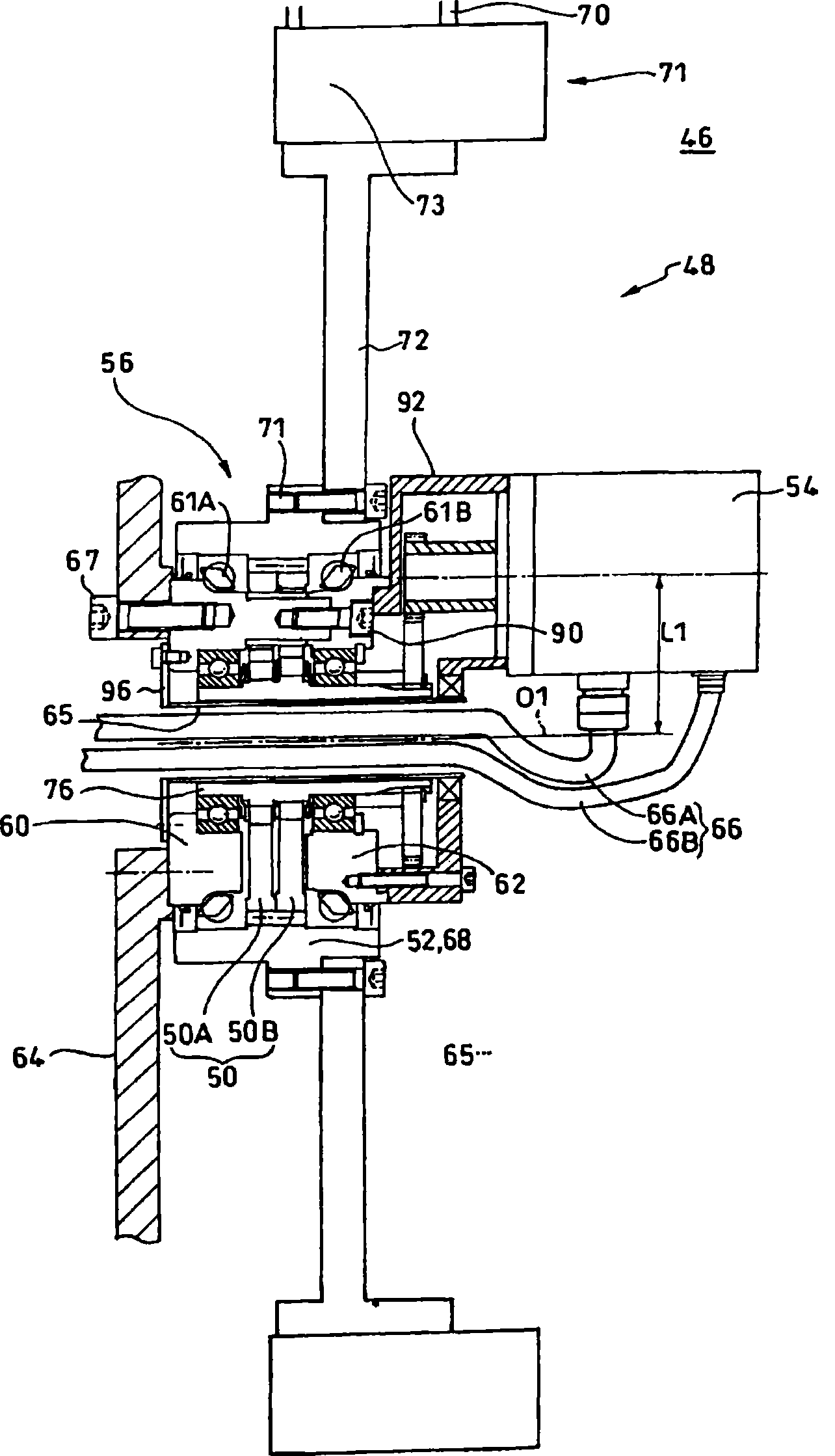

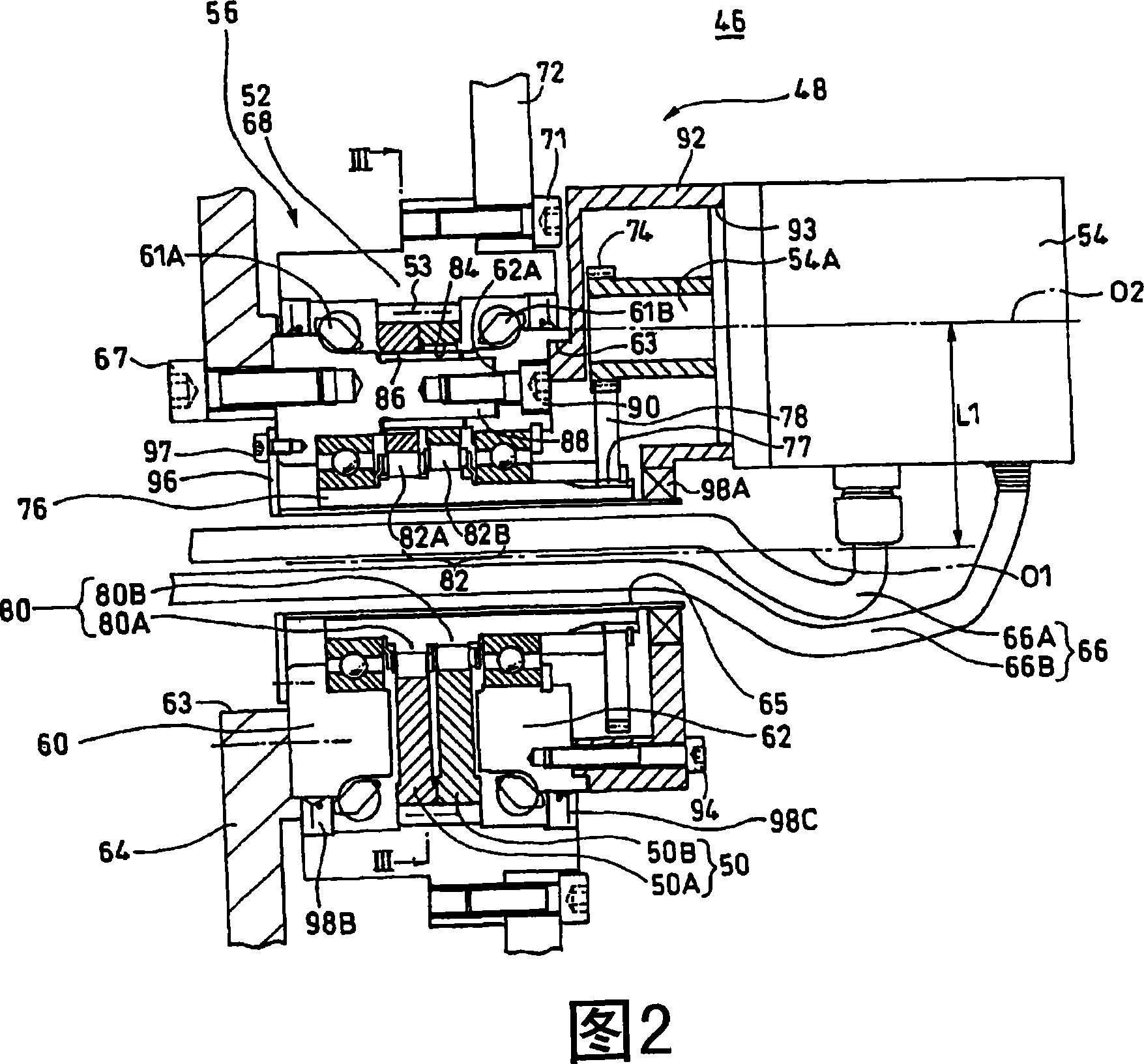

[0044] FIG. 1 is a longitudinal sectional view showing an example of an embodiment of a driving device of an automatic tool change mechanism according to the present invention, and FIG. 2 is an enlarged view of an essential part of FIG. 1 . In addition, FIG. 3 is a sectional view taken along arrow III-III line of FIG. 2 .

[0045] The description will start from the outline with emphasis on FIG. 1 . The driving device 48 of the automatic tool changer mechanism 46 includes a speed reducer 56 that decelerates and outputs the rotation of the motor 54 as relative rotation between the external gear 50 and the internal gear 52 . The external gear 50 oscillates and meshes internally with the internal gear 52 .

[0046] On both axial sides of the external gear 50 are provided first and second brackets 60 , 62 which are synchronized with the rotation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com