Ceramic coralene enamel base material and method for decoration by using the same

A technology of base materials and ceramics, applied in the field of ceramics, can solve the problems of high price of difficult raw materials, and achieve the effects of simple and convenient operation, increased high temperature viscosity, and strong flexibility

Inactive Publication Date: 2009-04-22

LONGDA BONE CHINA

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] The technical problem to be solved by the present invention is to provide a ceramic embossed decorative glaze base material and a method of using it for decoration, so as to solve the problems of the existing technology that it is difficult to perform glaze embossed decoration on three-dimensional objects and the raw materials are expensive

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 2

[0023] Embodiment 2: porcelain powder 60, frit 40.

Embodiment 3

[0024] Embodiment 3: Porcelain powder 50, frit 60.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

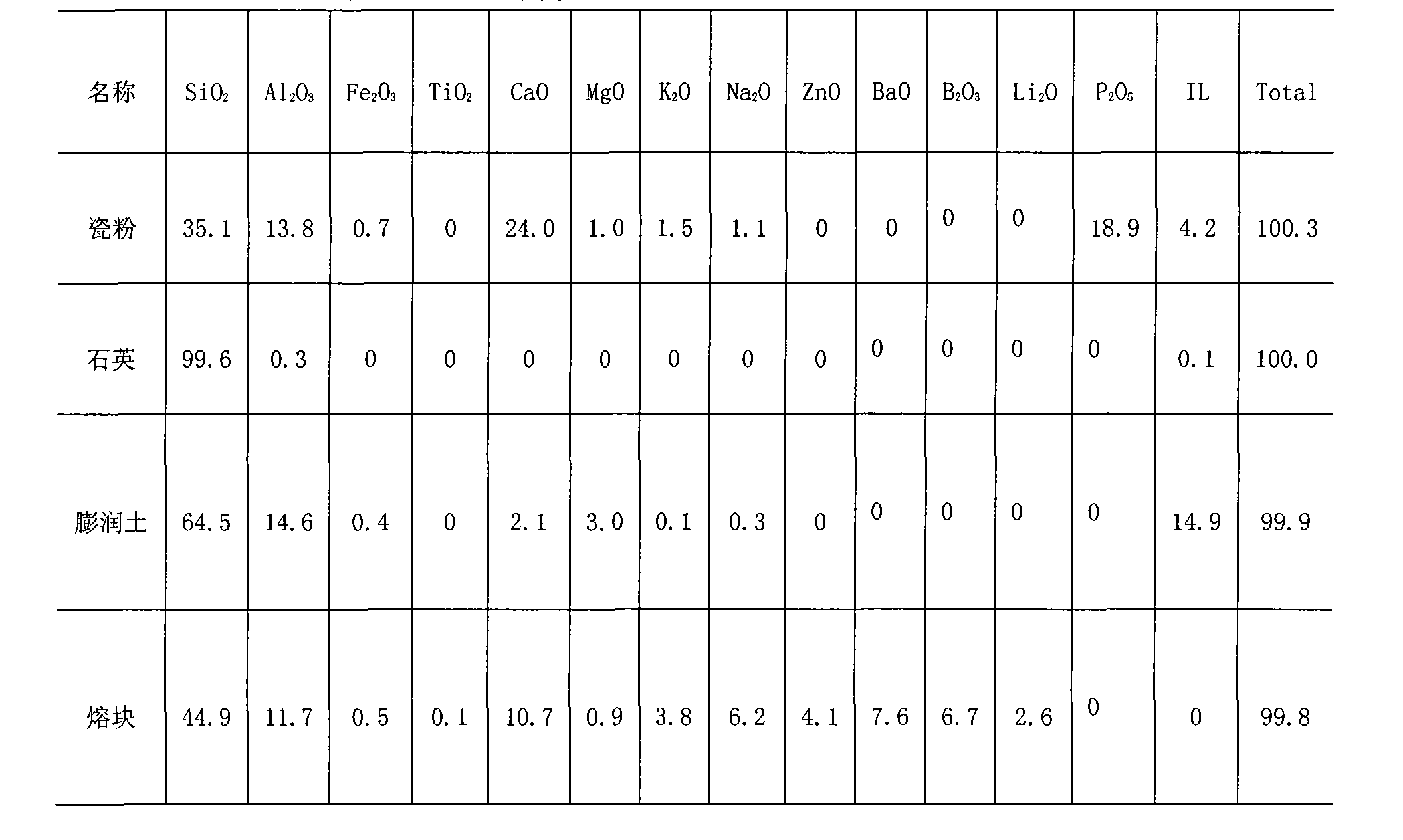

The invention relates to a glaze base stock for ceramic raised decoration and a method for decoration through using the glaze base stock, which belong to the technical field of ceramics. The glaze base stock is used to solve the difficult problems that the prior technology is difficult to carry out raised glazing decoration on a solid vessel shape and the raw material is expensive. The method comprises the following technical proposal: a glaze base stock consists of ceramic powder, a fusion cake and the like; and the method for using the glaze base stock to carry out raised glazing decoration comprises the steps of the preparation of the glaze base stock, the preparation of glaze pigment slurry, stippling, sintering and other process steps. The glaze base stock achieves remarkable effects. The glaze base stock for decoration is introduced with the ceramic powder, increases the high-temperature viscosity of the glaze base stock, is melted at high temperature but does not flow or deform, can freely stipple and decorate products with various vessel shapes, and has simple and convenient operation. With the glaze base stock, a process of raised glazing decoration can be widely applied and opens up a new field for the decoration and production of ceramics.

Description

technical field [0001] The invention relates to a ceramic glaze base material and a glaze embossing decoration method using the base material, which belongs to the technical field of ceramics. Background technique [0002] In ceramic production, embossing is a common decoration technology, mainly including body embossing and glaze embossing. The embossing of the green body needs to make a relief mold, and the green body is pressed through the mold to form a raised embossing effect, which is only suitable for flat products and mass production, and cannot be produced in a single way, lacking flexibility. Compared with the blank embossing, the glaze embossing decoration is crystal clear, soft and lustrous, and has a stronger decorative aesthetic feeling. But at present, the production of glaze embossing is restricted due to various reasons. First, the glaze embossing uses a large number of imported glazes, and its flux components are added with B203, Li20, SrO, etc., which is ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C04B41/86

Inventor 王金城

Owner LONGDA BONE CHINA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com