Nano essence dispersion and preparation thereof

A technology of dispersion and flavor, applied in the direction of essential oil/fragrance, fat production, etc., can solve the problems of numerous steps, high drying temperature, and difficulty in stable and long-lasting aroma, so as to achieve pollution-free production process, stable chemical properties, and stable and long-lasting aroma Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Flower essence and polyethylene glycol with molecular weight of 6000 are selected, and the weight ratio of flower essence and molecular weight is 5:95. Heat the polyethylene glycol to 60-80°C to melt, add flower essence to the melted polyethylene glycol, stir while adding to form a uniform flower essence-polyethylene glycol blend, cool naturally or at 4°C After accelerated cooling to room temperature, grind and pass through a 300-mesh sieve to obtain co-melt powder.

[0024] The co-melt powder obtained in this example has a characteristic aroma of typical flower essence, and the essence exists in the co-melt in the form of nanometers, and the aroma is stable.

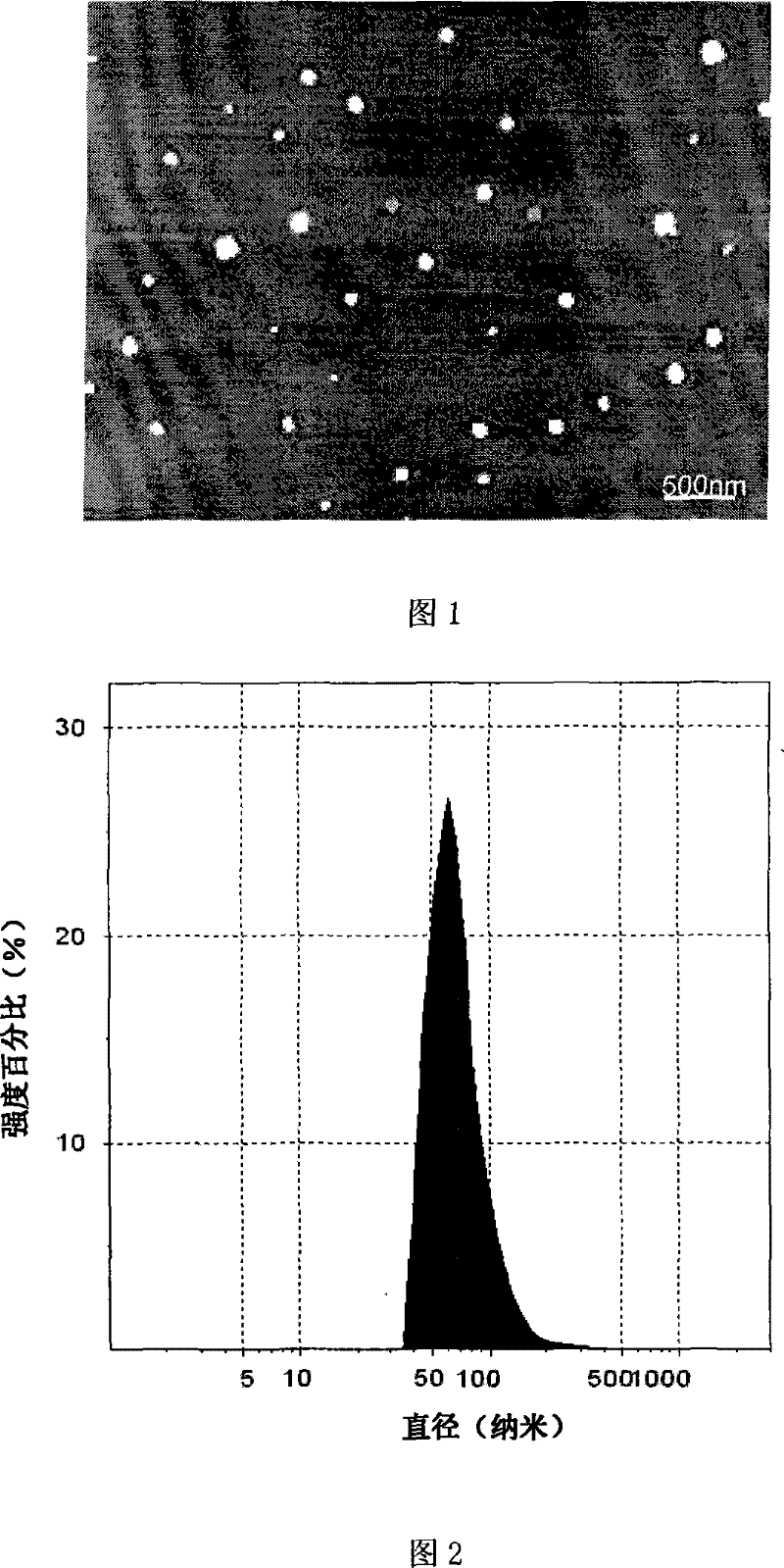

[0025] Dissolve the co-melt powder obtained in this example in water, and let it stand to form a nano-colloid solution with the co-melt obtained in this example as a solute. The colloid solution is dropped on a mica sheet and dried naturally, then scanned and observed with an atomic force microscope. figure 1 is...

Embodiment 2

[0027] The difference between this embodiment and embodiment 1 is that the weight ratio of flower essence and molecular weight is 10:90.

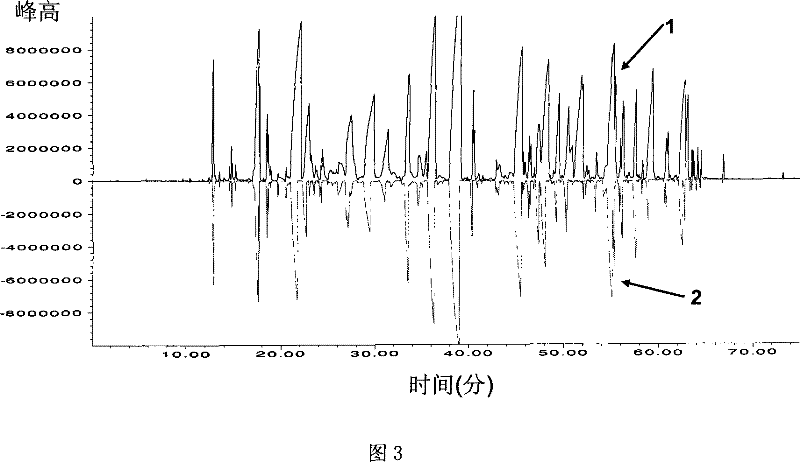

[0028] The eutectic powder obtained in this embodiment is dissolved in water, and left to stand to form a nano-colloid solution with the eutectic obtained in this embodiment as a solute, and the solute in the nano-colloid solution (that is, the co-melt obtained in this embodiment) is measured by the dynamic light scattering method. melt) diameter distribution, figure 2 is the obtained diameter distribution curve. From figure 2 It can be seen that the size of the eutectic particles obtained in this example in the colloidal solution is about 50nm-250nm.

Embodiment 3

[0030] The difference between this example and Example 1 is that: the weight ratio of flower essence and molecular weight is 15:85; the molecular weight of polyethylene glycol is 6000.

[0031] The eutectic powder obtained in this example is dissolved in water to form a nano-colloid solution, and the particle size of the colloid particles ranges from 50 nm to 250 nm as tested by a laser particle size analyzer and an atomic force microscope.

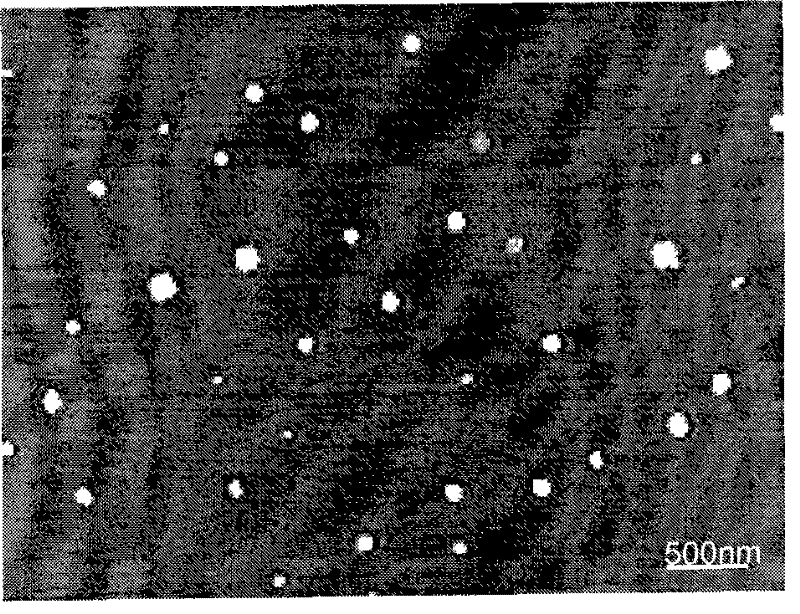

[0032] Apply gas chromatography-mass spectrometry (GC-MS) to analyze respectively the flower essence used in this embodiment and the co-melt powder obtained in this embodiment, the results are shown in image 3 , image 3 Curve 1 is the spectral line of the flower essence used in this embodiment, and curve 2 is the spectral line of the co-melt powder obtained in this embodiment. Comparing curve 1 and curve 2, it can be known that the nano-essence dispersion of the present invention will not affect the composition of the essence. Changes ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com