A five-spice powder mixer with baking function

A technology for five-spice powder and powder mixer, which is applied to mixers, mixers with rotary stirring devices, mixer accessories, etc., can solve the problems of bland food, not fully integrated, traditional taste, etc. Heat loss, energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

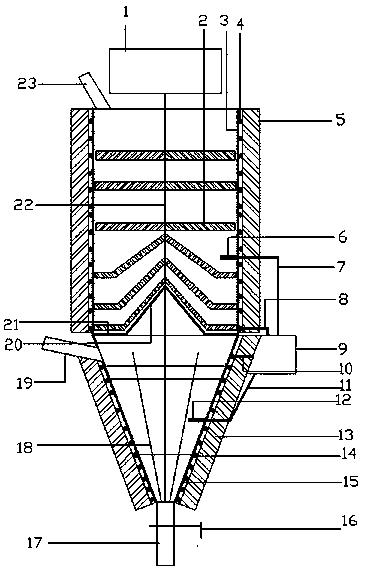

[0019] Embodiment 1. A powder mixing machine for five-spice powder with a baking function, including a motor 1, a first stirring wing 2, a first stirring barrel 3, a first resistance wire 4, a first energy-saving insulation layer 5, and a first thermoelectric Couple 6, first thermocouple wire 7, first resistance wire wire 8, controller 9, second resistance wire wire 10, second thermocouple wire 11, second thermocouple 12, second energy-saving insulation layer 13, second Resistance wire 14, second mixing tank 15, discharge pipe valve 16, discharge pipe 17, second stirring fin 18, lower feed port 19, sealing layer 20, annular dislocation valve 21, stirring shaft 22, upper feed port 23; wherein: the lower end of the motor 1 is connected to the stirring shaft 22, the stirring shaft 22 is respectively equipped with a first stirring fin 2 and a second stirring fin 18 from top to bottom, the first stirring barrel 3 is located at the upper end of the second stirring barrel 15, the firs...

Embodiment 2

[0028] Embodiment 2. A powder mixing machine for five-spice powder with a baking function, wherein: the first energy-saving insulation layer and the second energy-saving insulation layer are made of the following components in parts by weight: 2 parts of polystyrene foam, 2 parts of rice straw 25 parts of Portland cement, 15 parts of water, 12 parts of calcium carbonate, 4 parts of hydrogen peroxide, and 1.0 part of sodium lignosulfonate.

[0029] All the other are with embodiment 1.

Embodiment 3

[0030] Embodiment 3. A powder mixing machine for five-spice powder with a baking function, wherein: the first energy-saving heat preservation layer and the second energy-saving heat preservation layer are made of the following components in parts by weight: 3 parts of polystyrene foam, 3 parts of rice straw 30 parts of Portland cement, 20 parts of water, 15 parts of calcium carbonate, 5 parts of hydrogen peroxide, and 1.5 parts of sodium lignosulfonate.

[0031] All the other are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com