Design and structure of self-locking type rail base dynamic vibration absorber

A dynamic vibration absorber and self-locking technology, which is applied in the field of rail vibration and noise reduction, can solve the problems of increasing rail strength, high cost, and poor vibration damping effect, and achieves increased vibration quality, reduced rail amplitude, and easy installation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

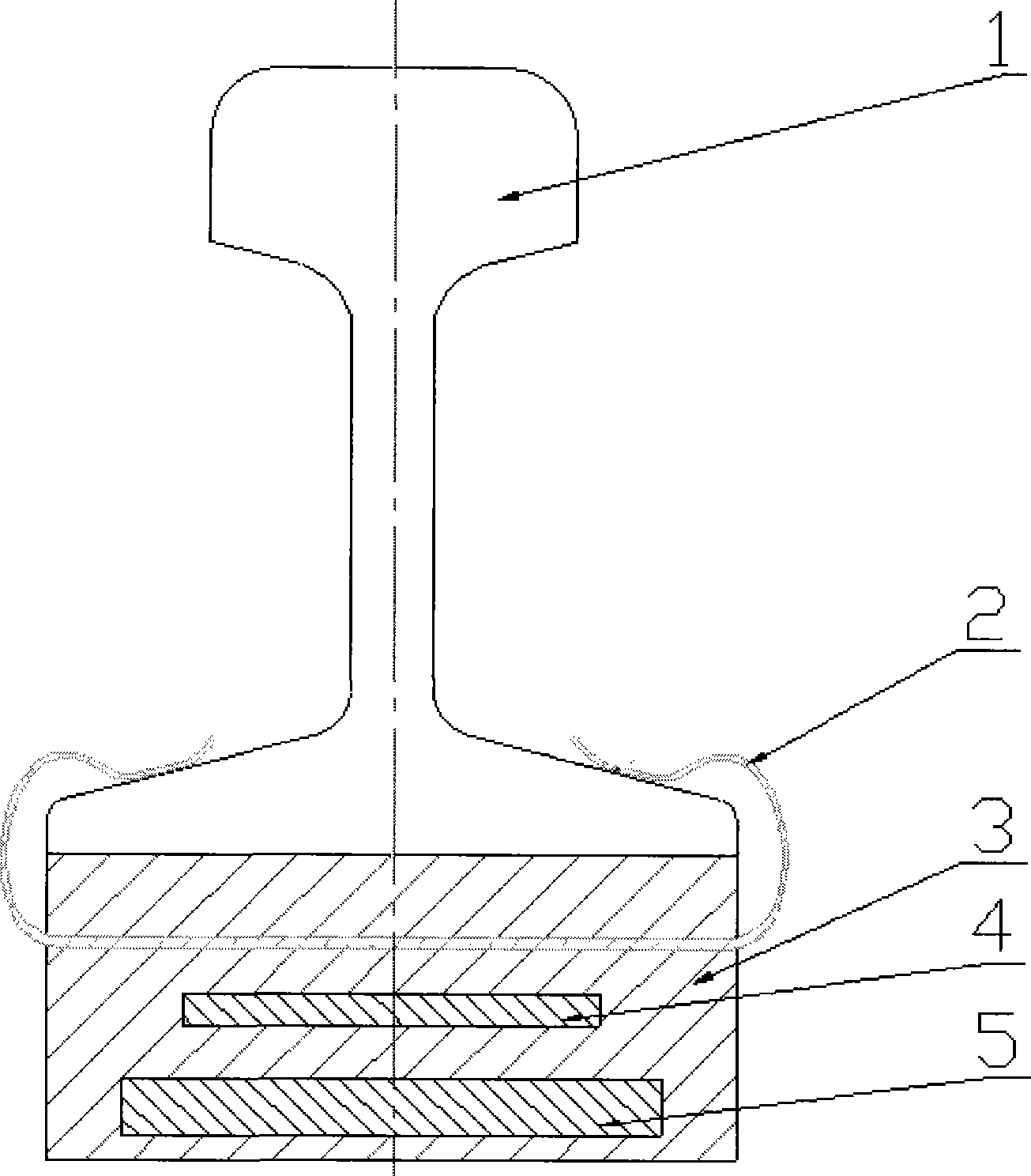

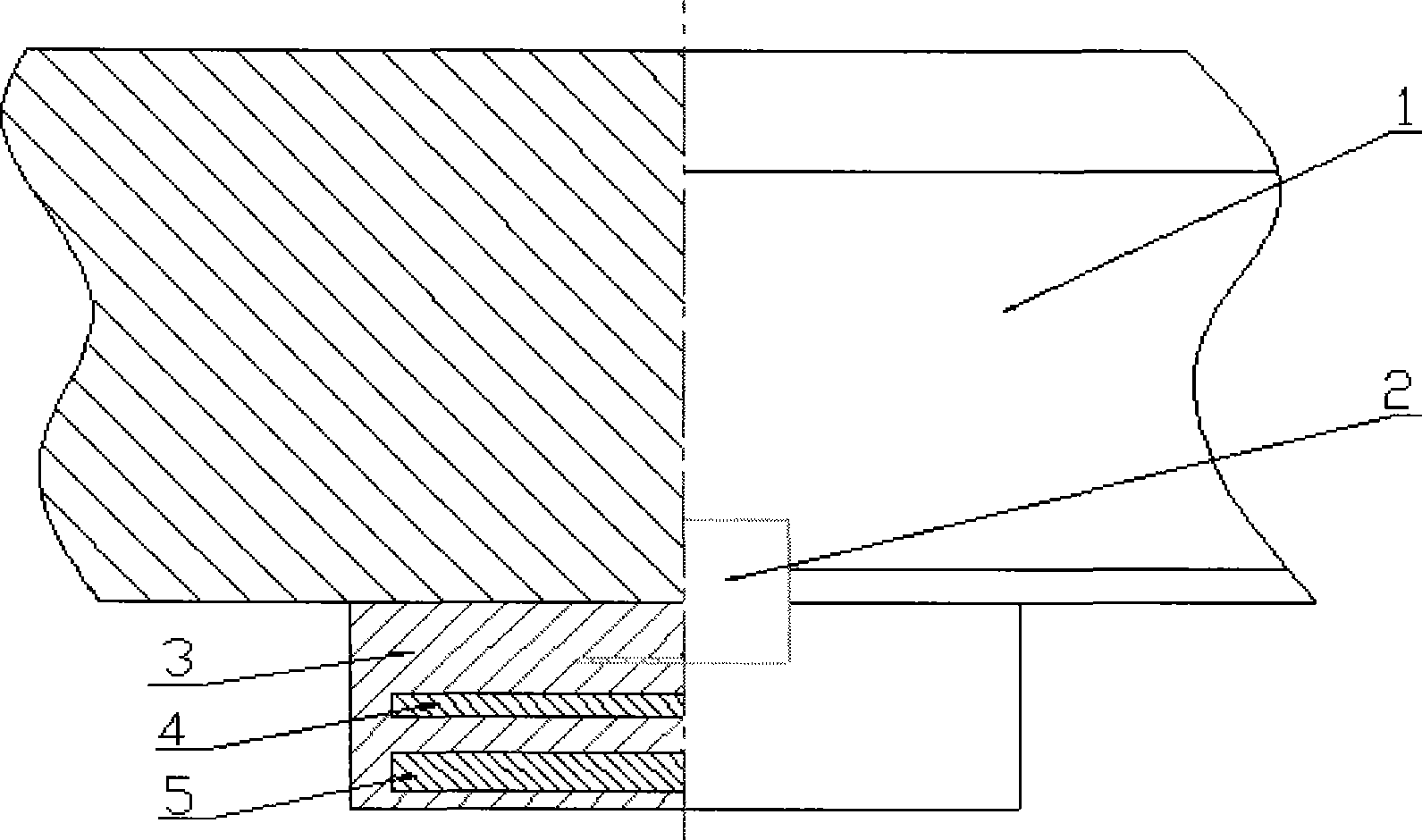

[0024] The design of the self-locking rail bottom dynamic vibration absorber of the present invention is to pave an elastic element under the rail, and the elastic element can be vulcanized rubber, or plastic, or a rubber-plastic blend. One or more resonant mass blocks are embedded in the middle of the elastic element through bonding or non-bonding. The shape of the resonant mass blocks can be regular or irregular, and the bonding method can be glue bonding, or Vulcanized bonding. The mass and distribution position of the resonant mass block are optimized according to the maximum vibration reduction amplitude. The elastic element and the resonant mass block form a multi-mode dynamic resonant mass-spring unit. The self-locking clip passes through the elastic element along the vertical direction of the rail and is clamped on the rail foot The side edges at both ends lock the elastic element to the bottom of the rail, and the fixing method of the self-locking magazine through the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com