Apparatus and method to compensate a driving current of a light emitting diode

A technology of light-emitting diodes and driving currents, which can be used in lighting devices, electric lamp circuit layouts, cathode ray tube indicators, etc., and can solve problems such as increasing the total cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

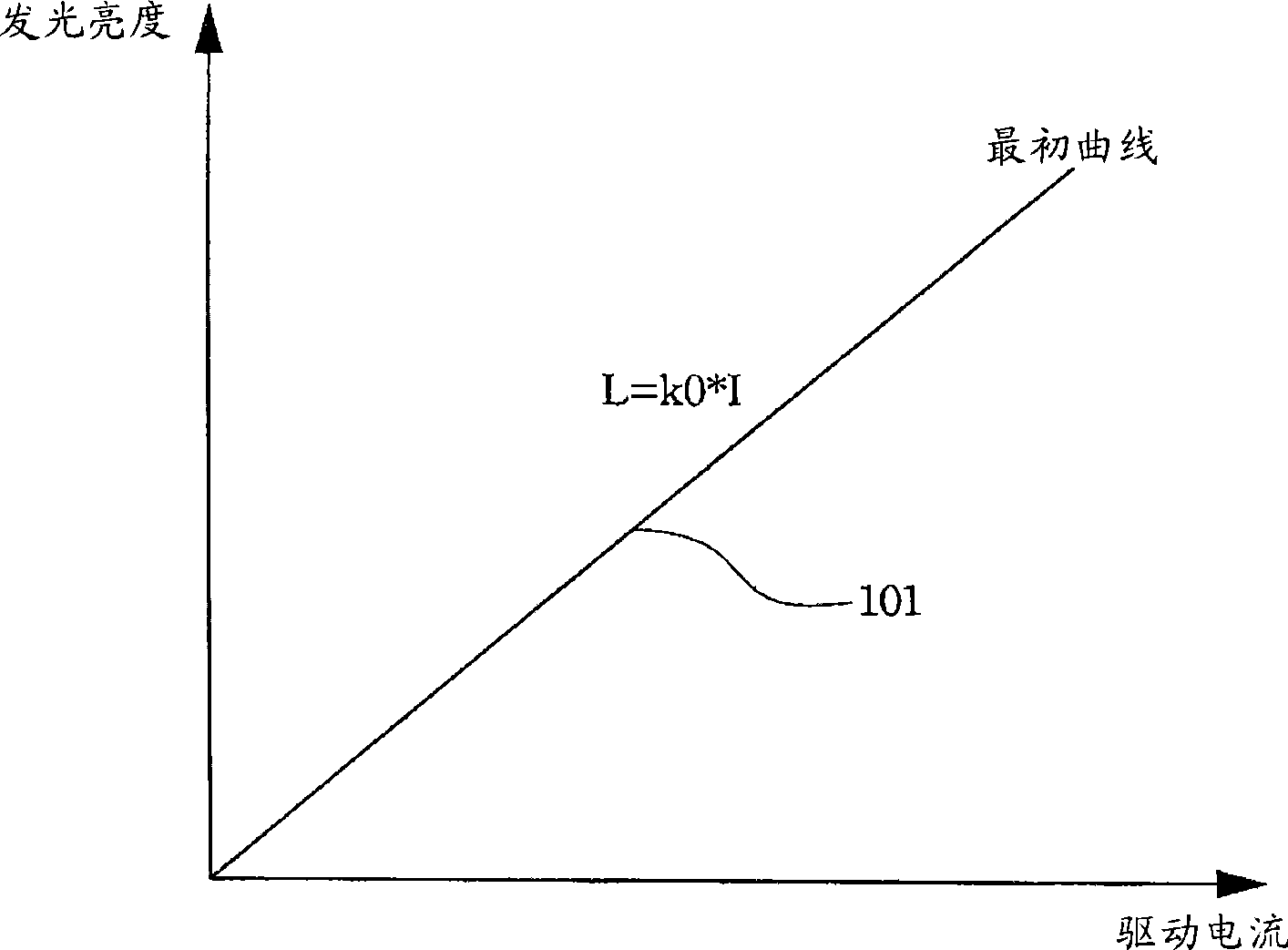

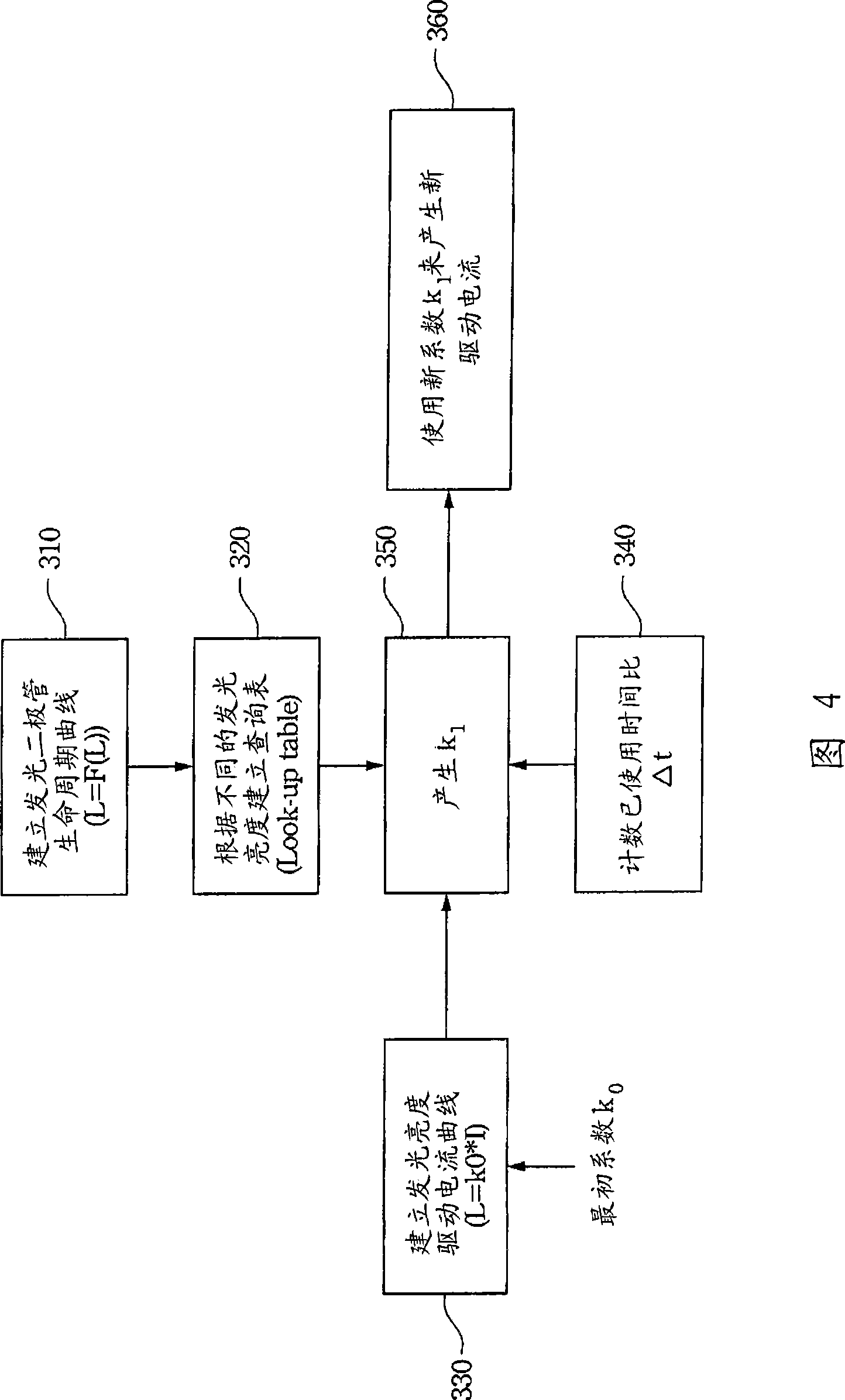

[0021] figure 1 Shown is a graph of luminous brightness and driving current, which is used to describe the relationship between the luminous brightness of an LED and the driving current. Among them, different light-emitting devices have different light-emitting brightness and driving current curves. The horizontal axis represents the driving current, and the vertical axis represents the luminance of light emission. According to curve 101, the luminous brightness is proportional to the driving current. In other words, the greater the driving current, the stronger the luminous brightness. The relationship between the two can be expressed by the following formula:

[0022] L=K×I

[0023] Wherein L represents the brightness, I represents the driving current, K is the slope of the curve and the coefficient for obtaining a luminous brightness under a driving current.

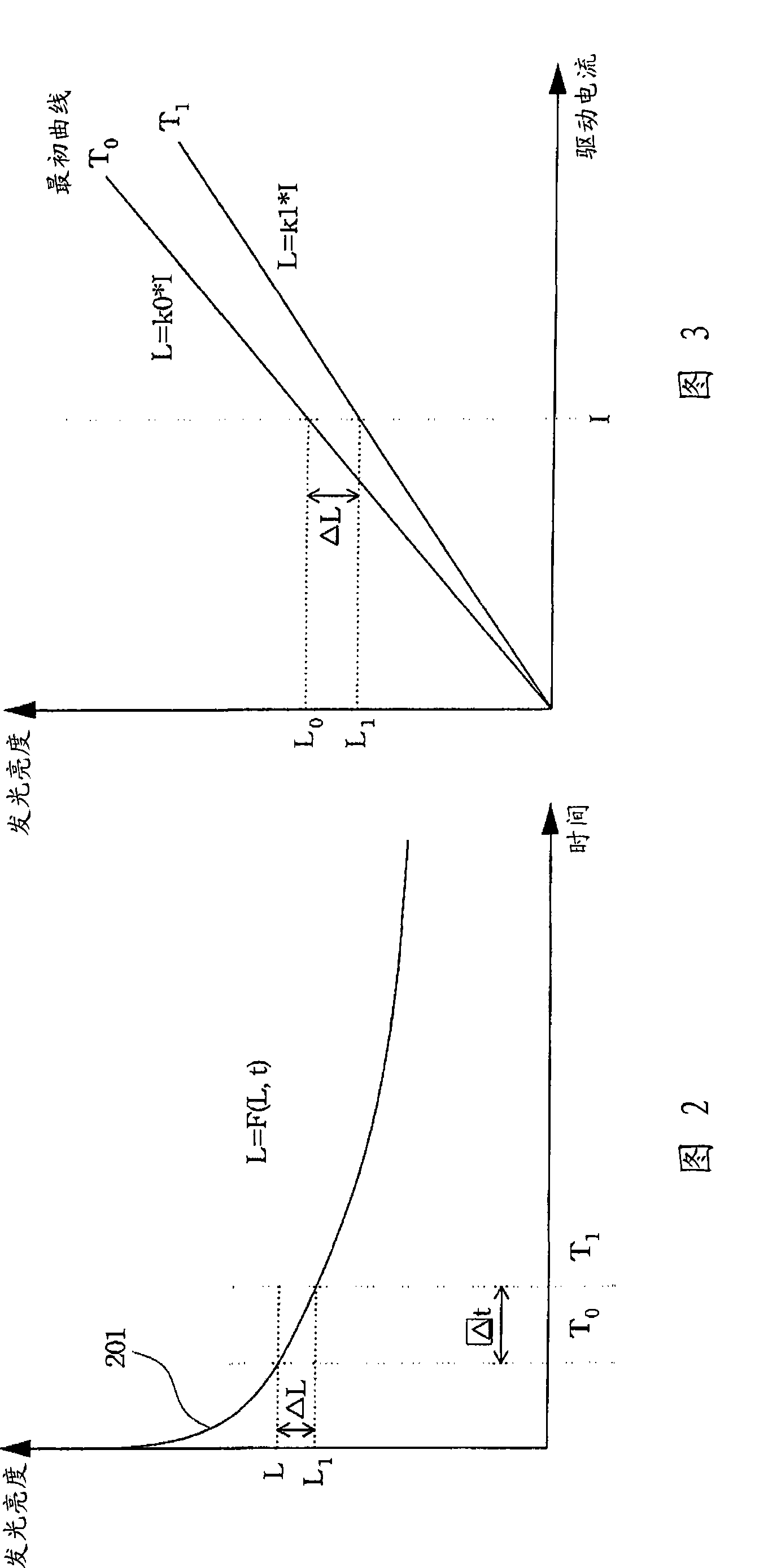

[0024] However, the luminous brightness under a constant current will decrease with the increase of the use time...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com