Method for implementing liquid crystal display drive circuit and source pole drive circuit module

A driving circuit and liquid crystal display technology, applied in static indicators, instruments, etc., can solve problems such as the difficulty of area design, and achieve the effects of low power consumption, high degree of integration, and small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A method for realizing a liquid crystal display drive circuit, characterized in that:

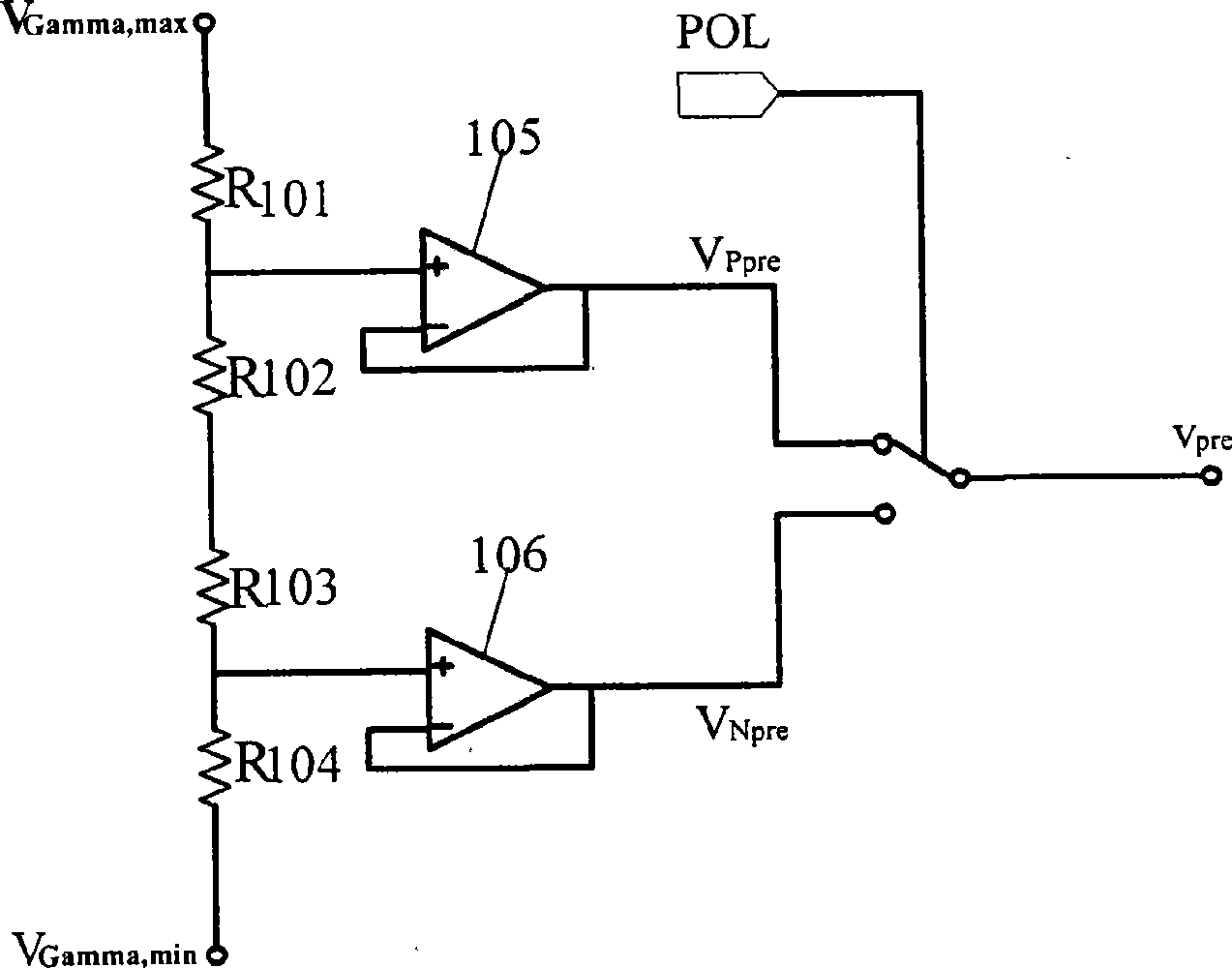

[0029]In the first step, the maximum gamma voltage (VGamma, max) and the minimum gamma voltage (VGamma, min) are respectively used as the input voltages of the precharge voltage generation circuit (100), and the positive polarity is generated by the precharge voltage generation circuit (100). The precharge voltage Vpper and the negative polarity precharge voltage Vnper, the voltage value of the positive polarity precharge voltage Vpper is the sum of 3 / 4 of the maximum gamma voltage (VGamma, max) and 1 / 4 of the minimum gamma voltage (VGamma, min), The voltage value of the negative polarity precharge voltage Vnper is the sum of 1 / 4 the maximum gamma voltage (VGamma, max) and 3 / 4 the minimum gamma voltage (VGamma, min); according to the polarity (POL) of the line to be displayed, select The positive polarity precharge voltage Vpper or the negative polarity precharge voltage Vnper is use...

Embodiment 2

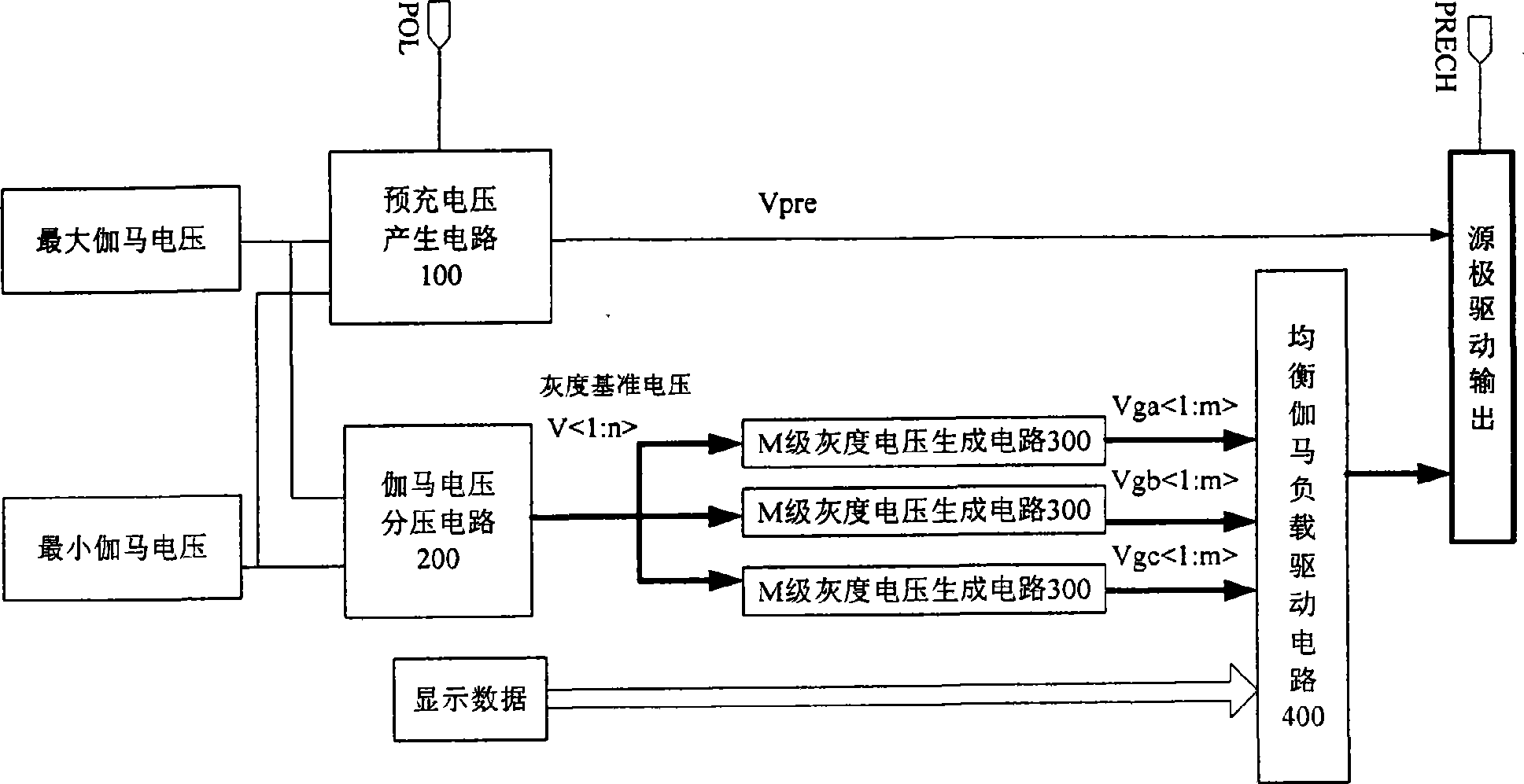

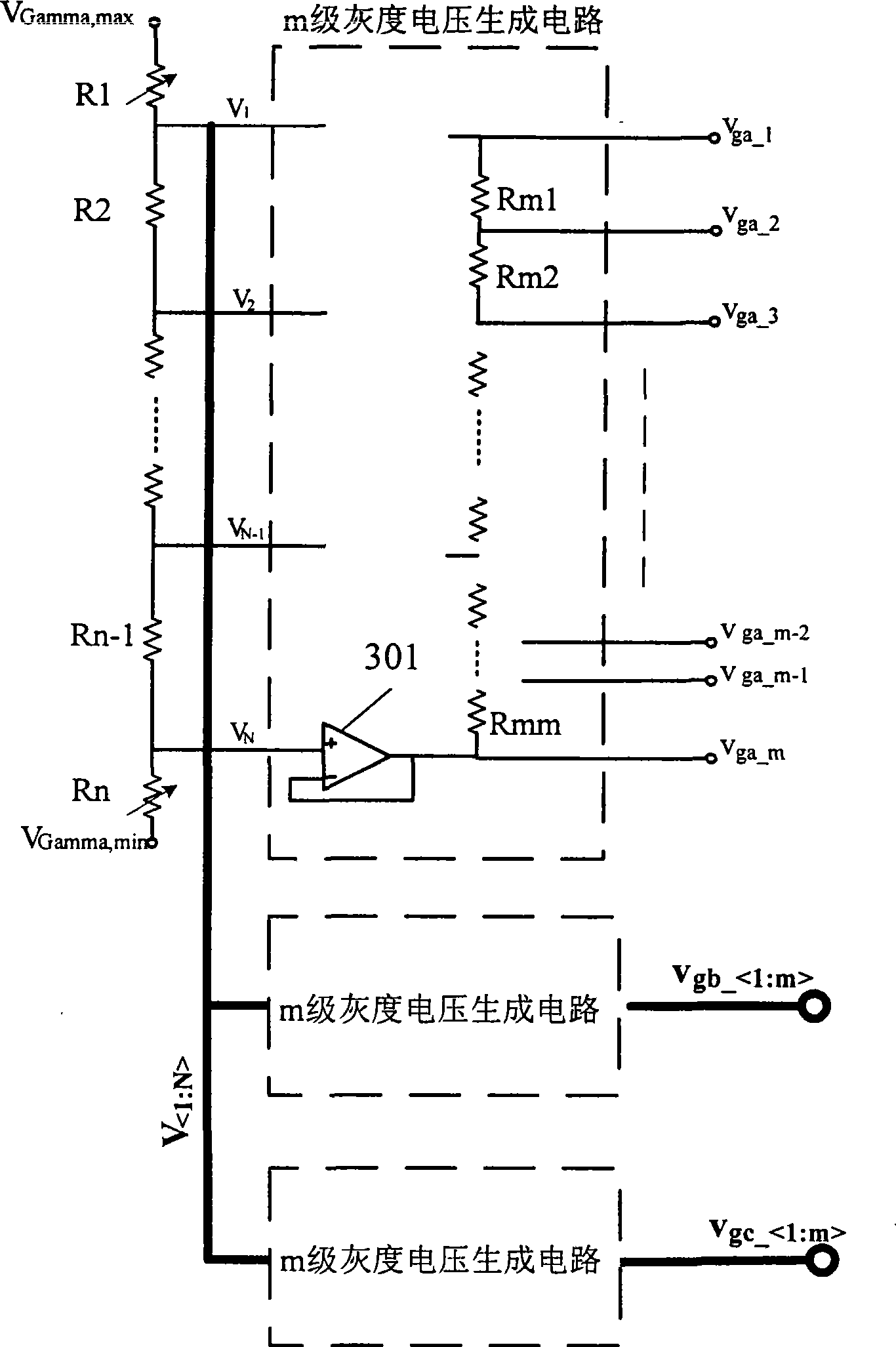

[0034] A source drive circuit module, composed of a precharge voltage generation circuit 100, a gamma voltage divider circuit 200, 2 to 4 sets of M-level grayscale voltage generation circuits 300 and a balanced gamma load drive circuit 400, the maximum gamma voltage (VGamma, max) and the minimum gamma voltage (VGamma, min) are respectively connected to the input terminals of the precharge voltage generation circuit 100 and the gamma voltage divider circuit 200, and the output of the precharge voltage generation circuit 100 is the precharge voltage Vper , the precharge voltage Vper is the positive polarity precharge voltage Vpper or the negative polarity precharge voltage Vnper; the output of the gamma voltage divider circuit 200 is N grayscale reference voltages V 1 , V 2 ,...,V N , N gray scale reference voltage V 1 , V 2 ,...,V N Three sets of M-level grayscale voltage generating circuits 300 are respectively connected, and the outputs of the M-level grayscale voltage ge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com