Inner imbedded type multifunctional integration type structure for integration protection element and preparation method thereof

A protection component and multi-functional technology, applied in the field of embedded multi-functional integrated structure and its production, can solve the problems of single function, cost consumption, and occupying the volume of electronic products, so as to increase functionality, reduce number, and reduce volume Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

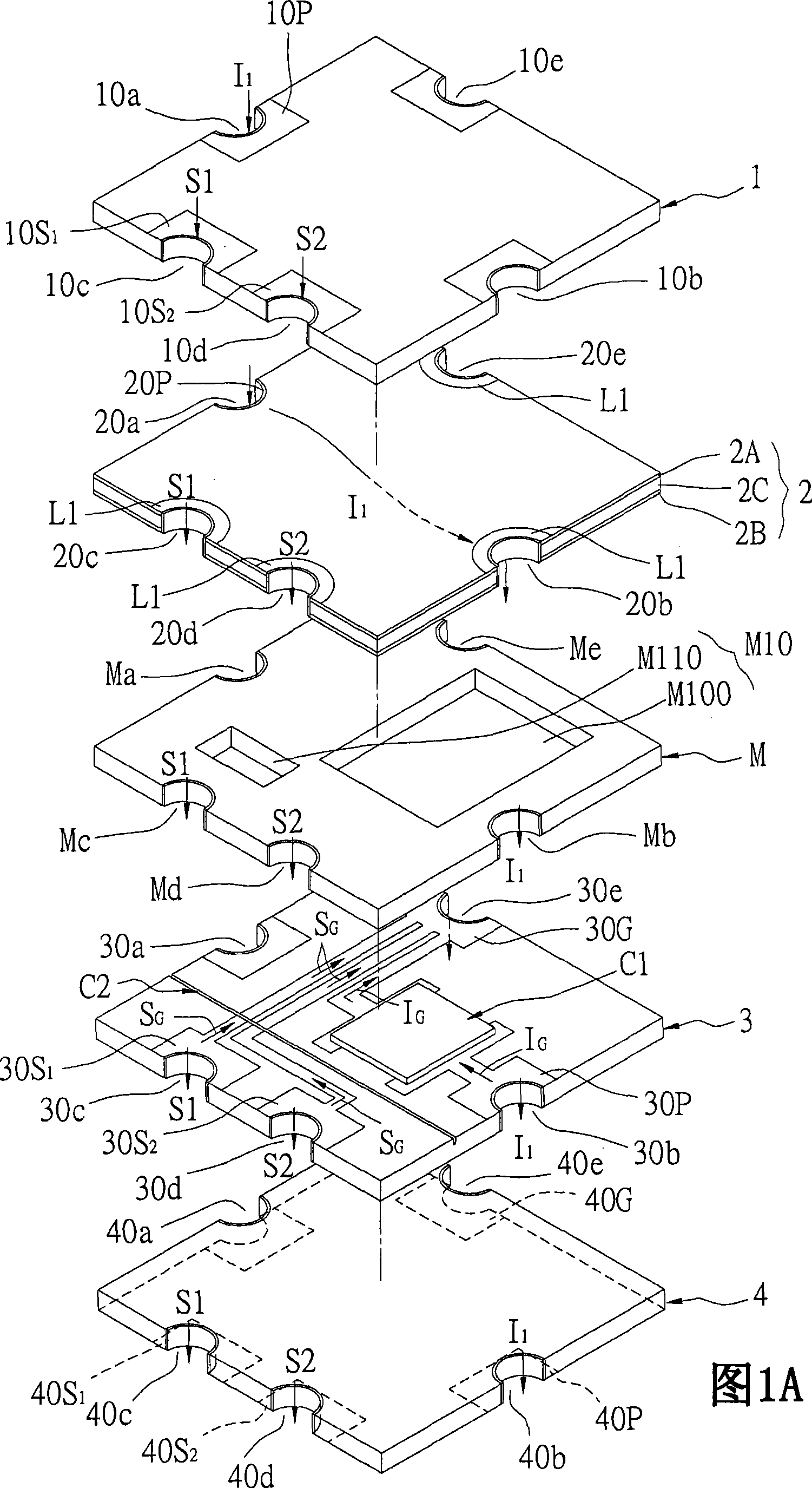

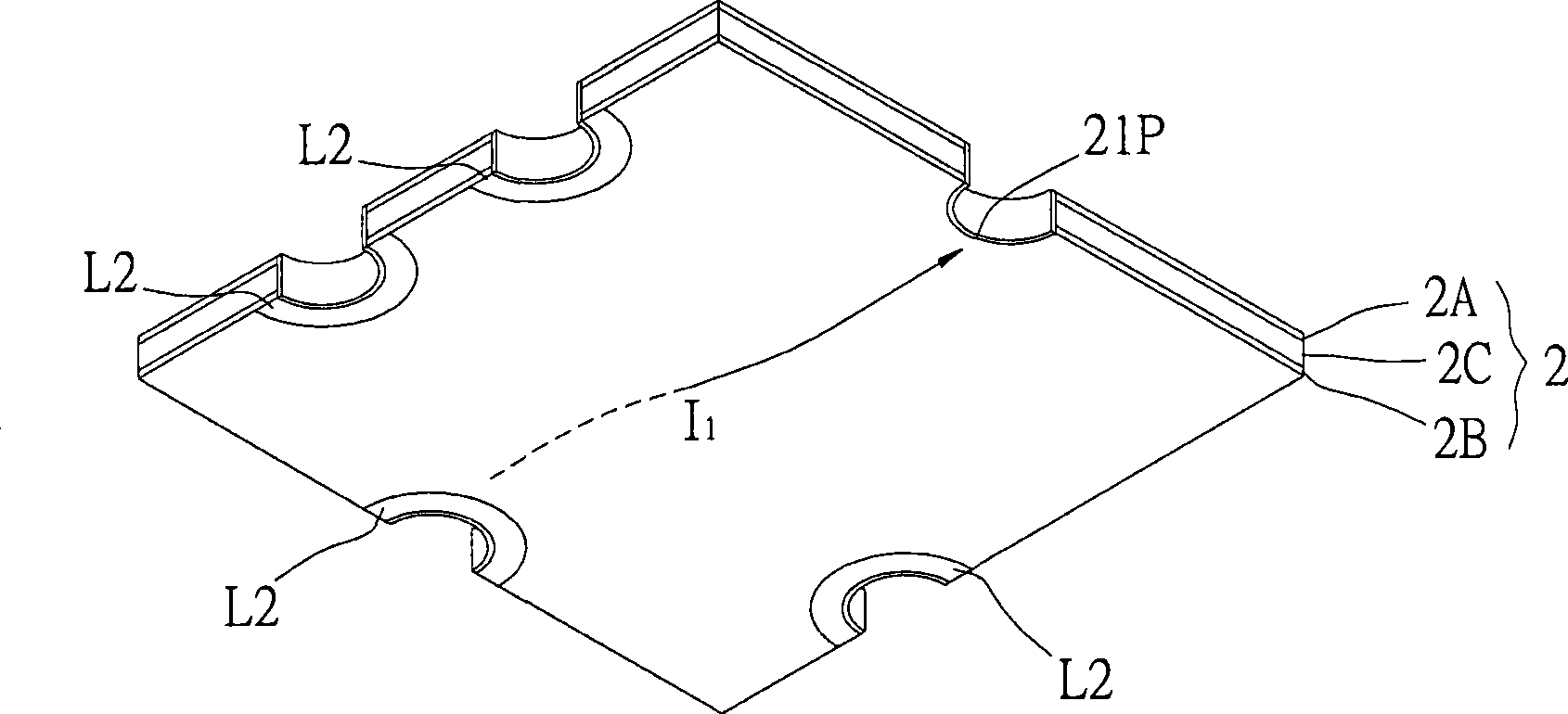

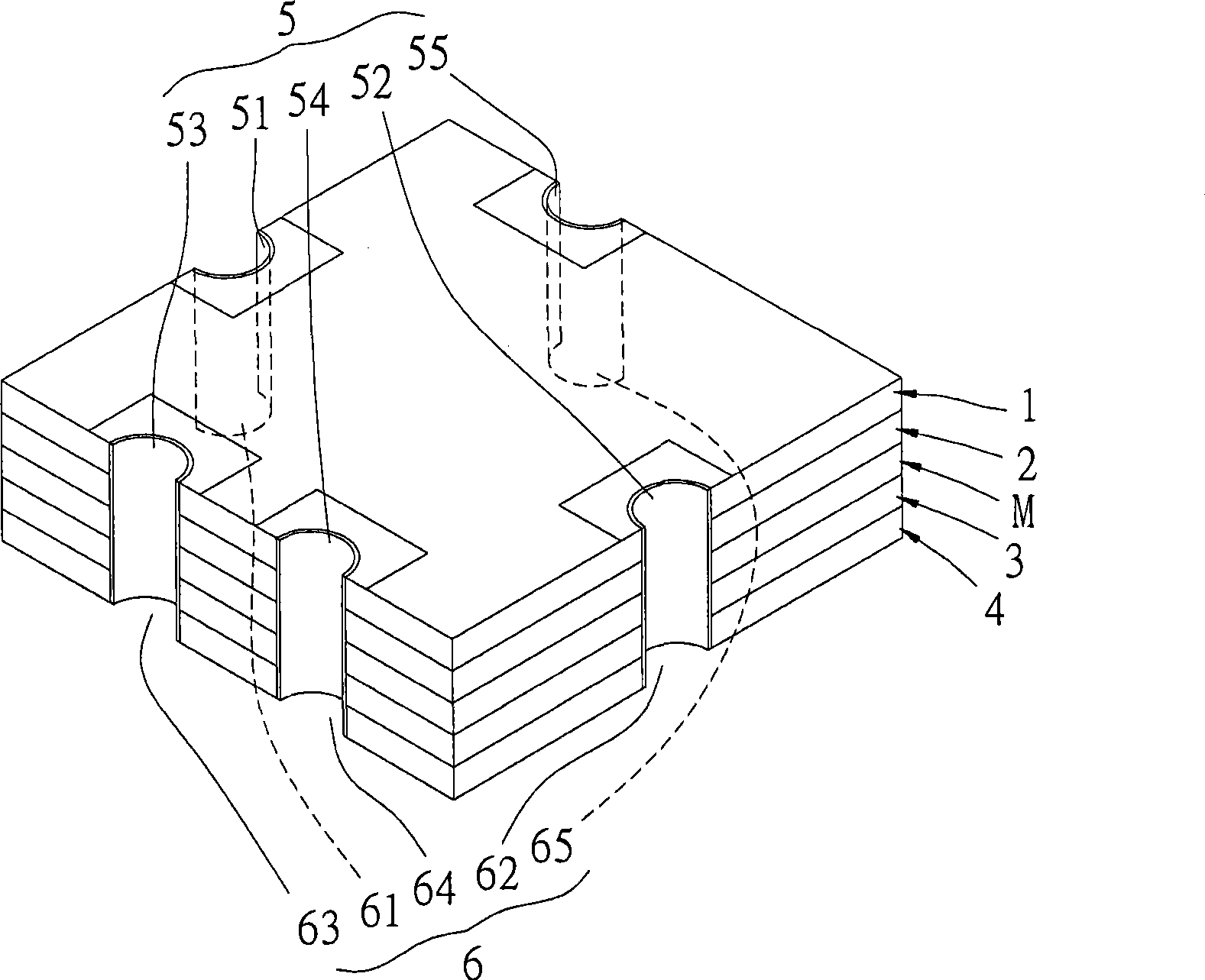

[0125] Please refer to Figure 1A to Figure 1C As shown, they are respectively a three-dimensional exploded view of the first embodiment of the embedded multifunctional integrated structure of the integrated protection element of the present invention, another perspective view of the overcurrent protection layer of the first embodiment of the present invention, and the present invention The invention is a three-dimensional assembly diagram of the first embodiment of a built-in multifunctional integrated structure integrating protection elements.

[0126] Please refer to Figure 1A and Figure 1C As shown, the embedded multifunctional integrated structure of the integrated protection element provided by the present invention includes: an upper cover insulating layer 1, an over-current protection layer 2, an intermediate insulating layer M , A multifunctional protection layer 3, a bottom cover insulating layer 4, and a side conductive unit 5. Wherein, the upper cover insulating layer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com