Drawer type circuit breaker bus system

A technology of drawer type circuit breaker and busbar, which is applied in the direction of pull-out switchgear, busbar/line arrangement, switchgear, etc., can solve the problems of reducing the effective current-carrying cross-section, poor working reliability, hidden safety hazards, etc., and achieve structural Compact, reliable action, and the effect of solving stuck cards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

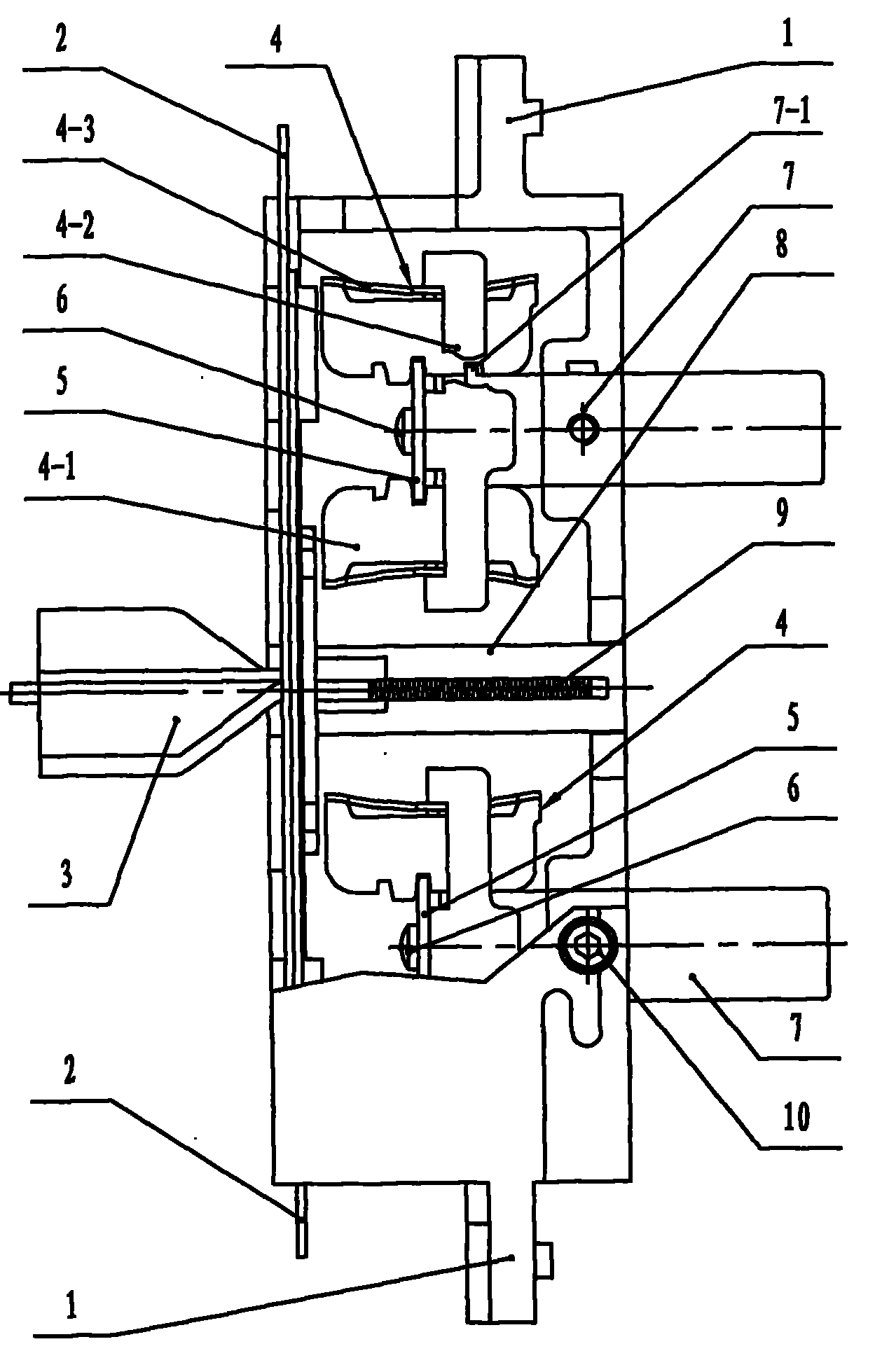

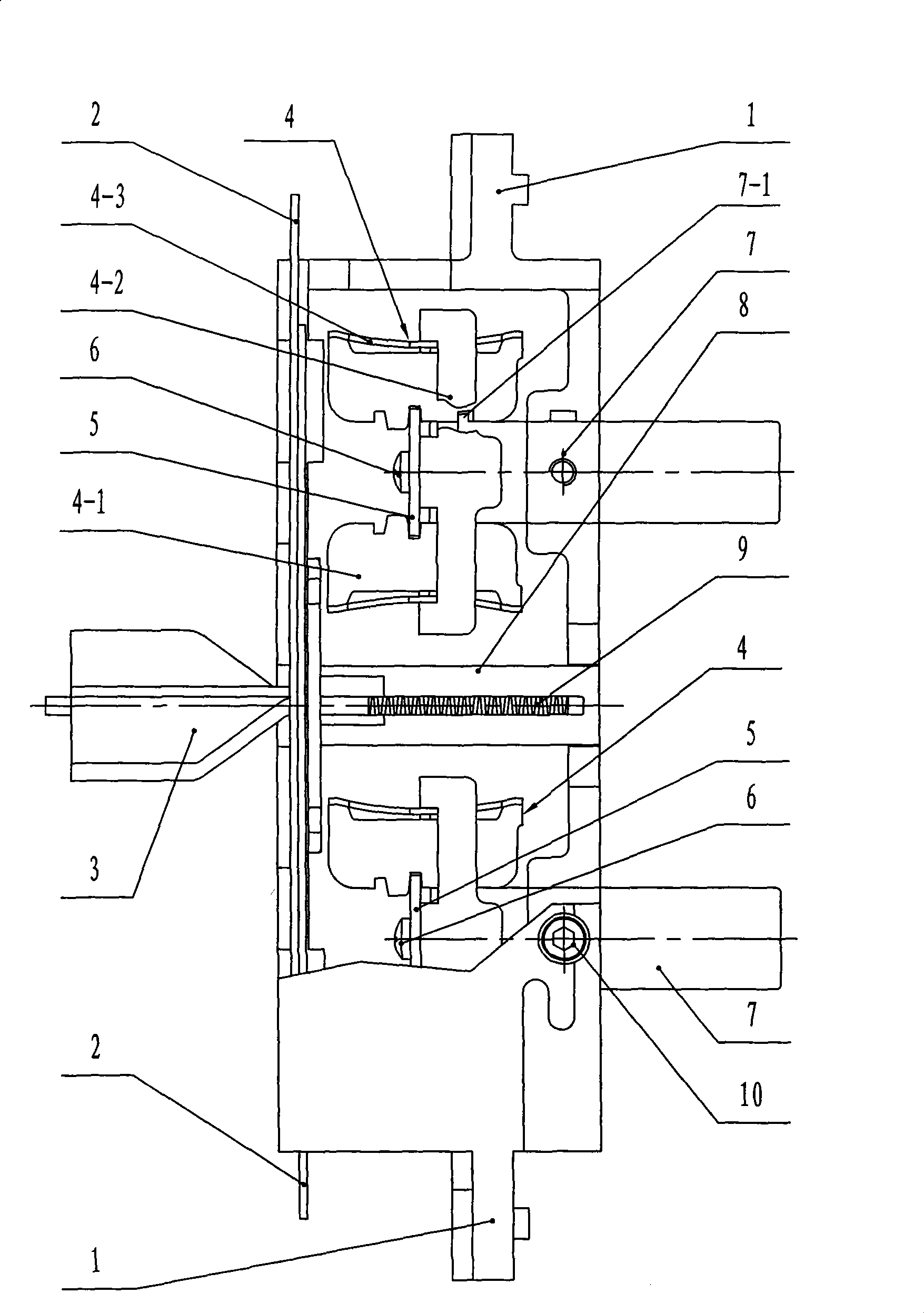

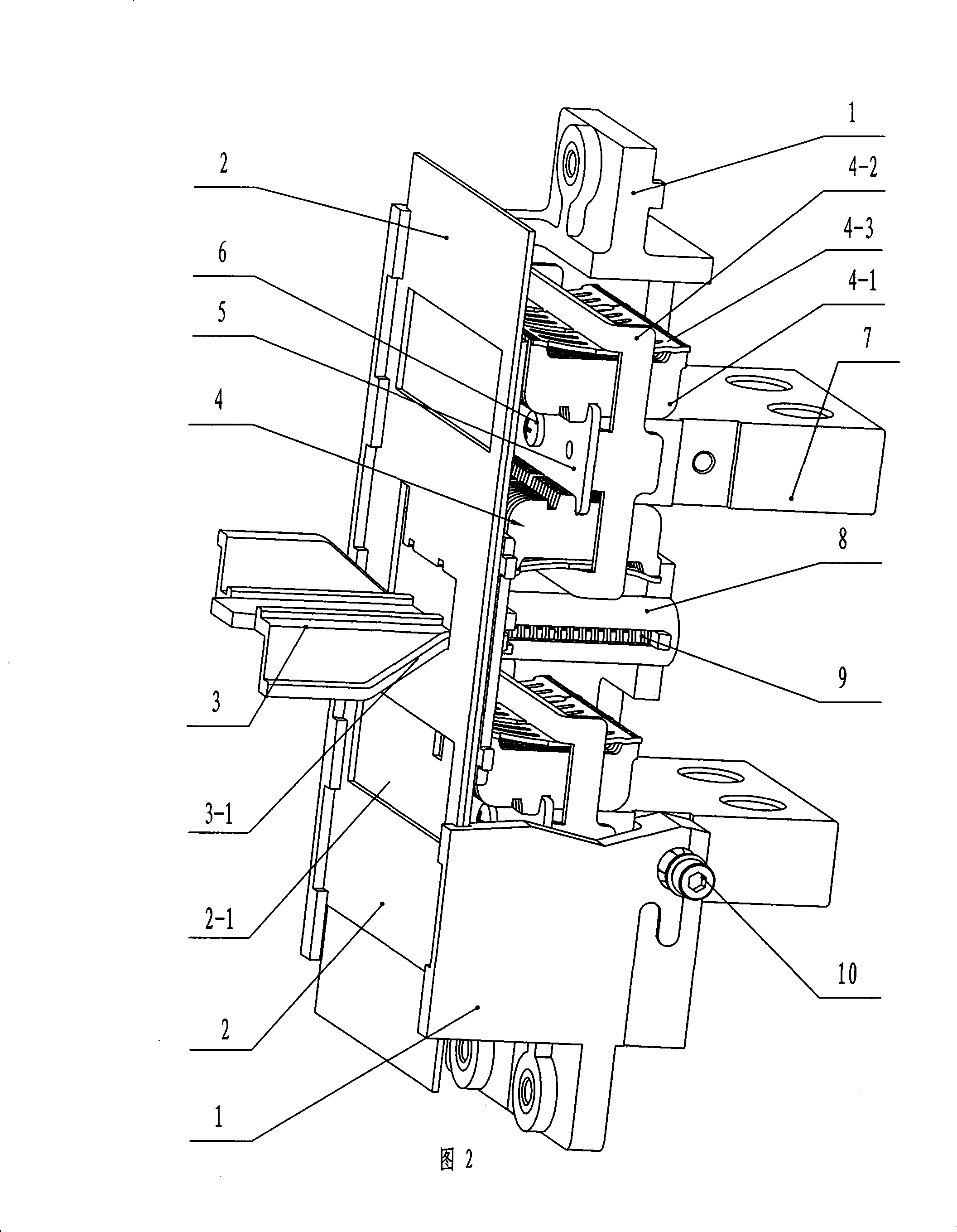

[0018] As shown in Figures 1 to 5, the drawer-type circuit breaker busbar system of the present invention includes an independent unit composed of a base, a connecting device and an isolating device installed on the base. As shown in Figures 1, 2, 3, and 5, the base of the present invention is composed of two connected seats, which are symmetrically and snapped together, or asymmetrically connected, and the two seats 1 are connected by fasteners 10 There is a guide groove 1-1 on one side of the seat body 1 for installing two insulating plates 2, and a support groove 1-4 is provided in the middle of the other side of the seat body 1, and there are positioning grooves on both sides of the support groove 1-4 Or positioning platform 1-2, used for installing busbar 7.

[0019] As shown in Figures 1 and 2, the connection device of the present invention includes two sets of bridge contacts 4, frame plates 5 and busbars 7. Sheet 4-1 and leaf spring 4-3 and support 4-2 are formed, two...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com