Droplet deposition apparatus

A deposition device and droplet technology, applied to the components of the droplet deposition device and the cover of the droplet deposition device, can solve the problems of performance degradation, pressure loss, etc., reduce the possibility, improve the service life, and simplify the manufacturing process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

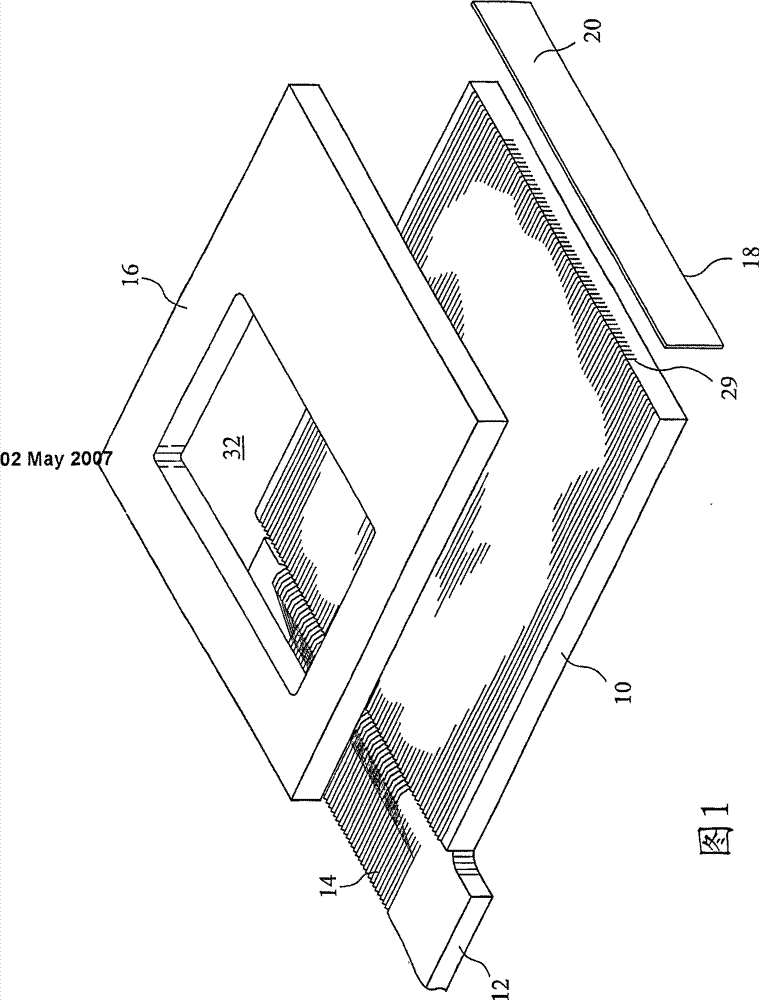

[0038] figure 1 An exploded perspective view shows an inkjet print head incorporating a piezoelectric wall actuator operating in shear mode. The inkjet print head includes a substrate 10 made of piezoelectric material mounted on a circuit board 12, and only the portion of the circuit board 12 that shows the connecting printed lines 14 is shown. A plurality of elongated channels 29 are formed in the base. The cover 16 bonded to the substrate 10 during assembly is shown above its assembled position. A nozzle plate 18 is also shown near the base of the print head, and a plurality of nozzles (not shown) are formed in the nozzle plate. The nozzle plate 18 is generally a polymer sheet coated with a low energy surface coating 20 on the outer surface.

[0039] figure 1 The illustrated cover 16 is formed of a material thermally matched to the base member 10. One solution is to use piezoelectric ceramics similar to those used for the substrate, so that when the cover is bonded to the su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com