Glass cutting apparatus with bending member and method for cutting glass using thereof

A bending unit, glass cutting technology, applied in glass cutting devices, glass production, glass manufacturing equipment and other directions, can solve the problems of low quality of the cutting end of the glass plate, the cutting process is not easy to carry out, etc., to achieve easy cutting process, simple structure, Cutting process and fast results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

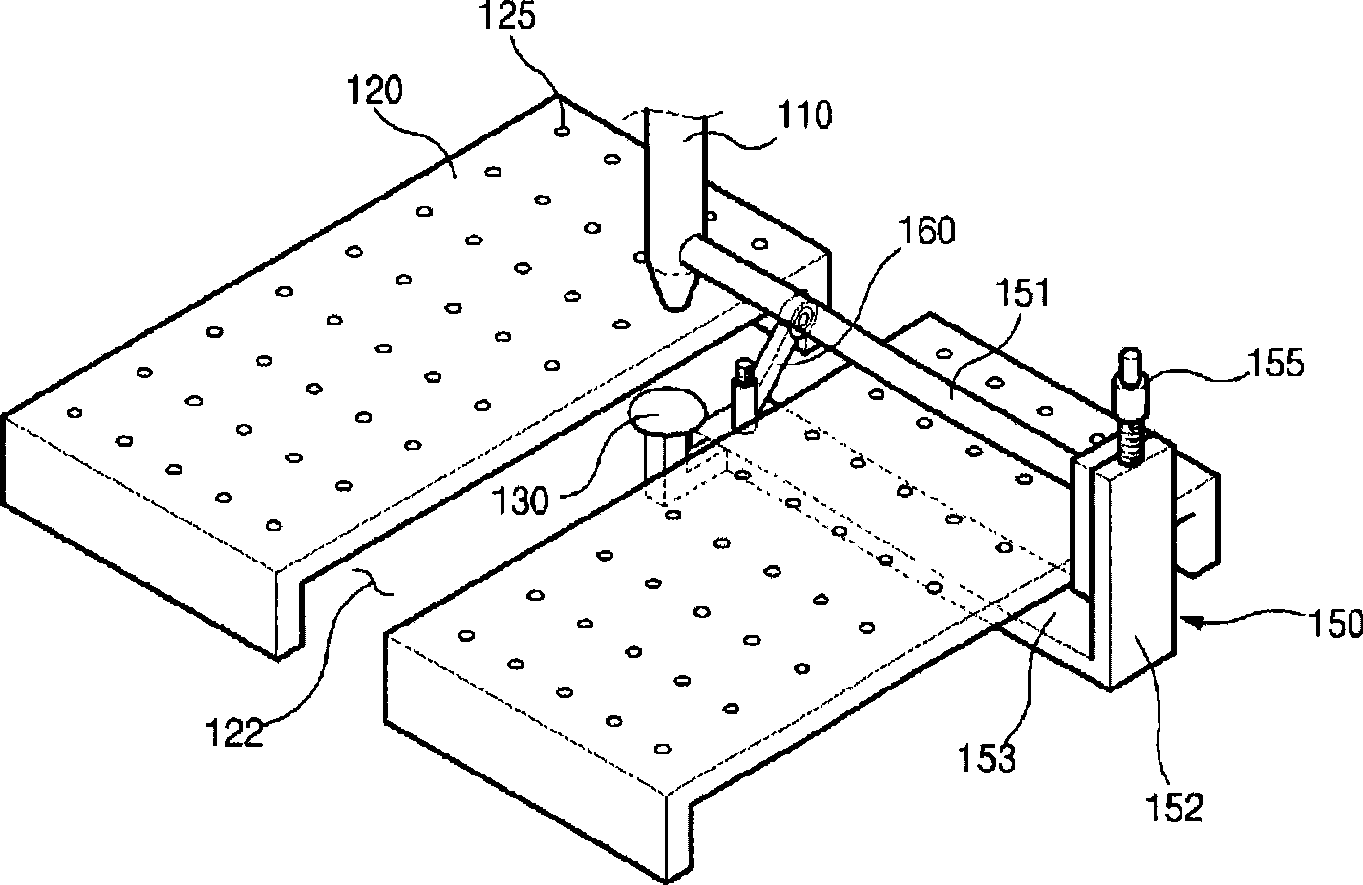

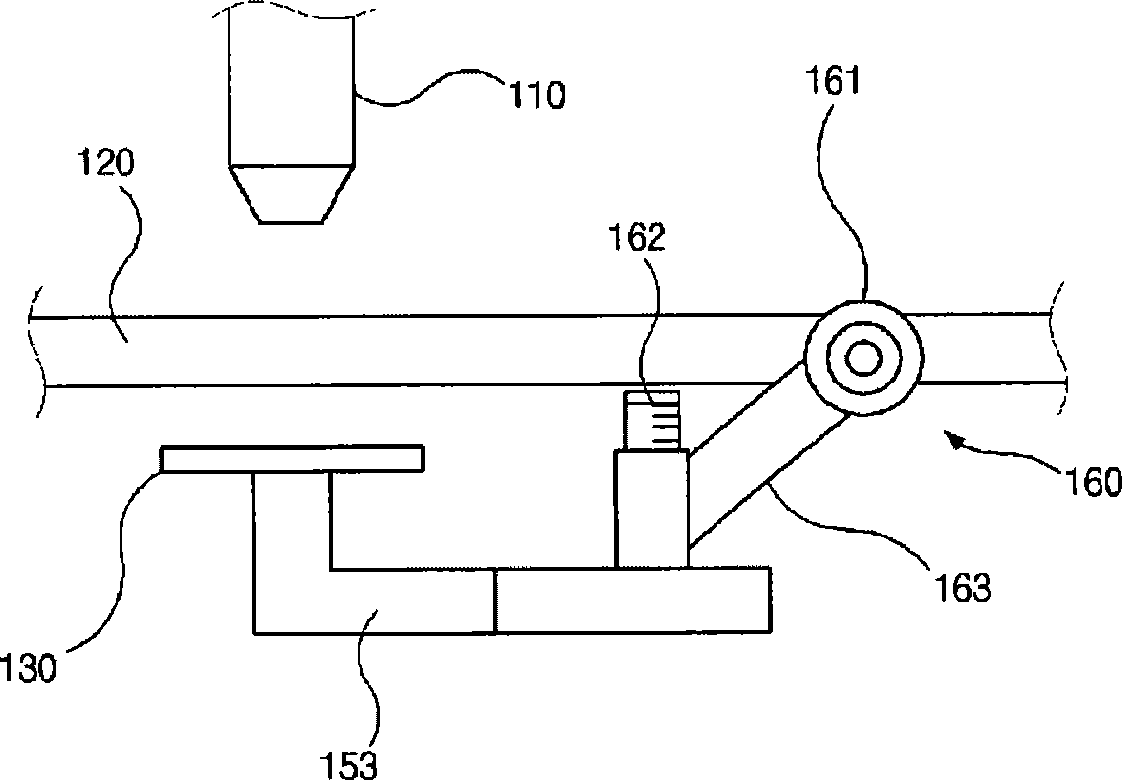

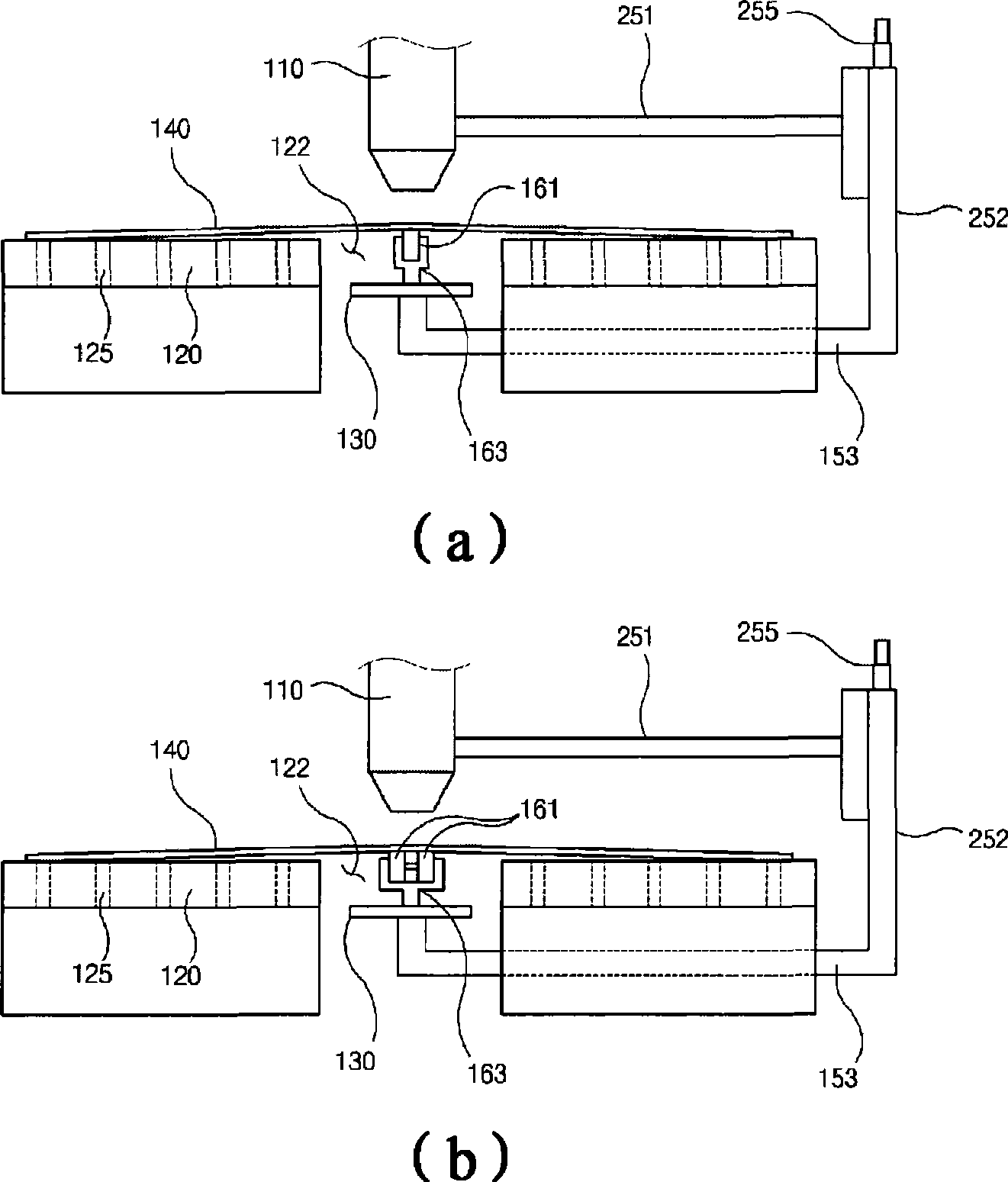

[0035] In order to achieve the above object, on the one hand, the present invention provides a glass cutting device, which includes: a laser generating unit that generates a laser beam and irradiates the laser beam onto a glass plate while moving forward or backward; a platform unit , which is arranged under the laser generating unit and supports the glass plate, and a guiding channel is formed at the middle position of the platform unit; a bending unit is arranged in the guiding channel at a position adjacent to the laser generating unit, and the curved the upper end of the unit is higher than the upper surface of the platform unit and is in contact with the glass plate; and a moving member that moves the bending unit.

[0036] The bending unit may include: a main body moving back and forth along the guide channel; rollers or balls disposed on an upper end of the main body and contacting the glass plate; and a bending height adjusting member for adjusting the height of the rol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com