Electric pug mill for making soil sample of specific moisture content

A technology of moisture content and soil mixer, applied in mixers, mixers, mixer accessories and other directions with rotating mixing devices, can solve the problems of affecting the experimental results, dead angles in mixing, improper control of mixing force, etc., to expand the contact area. , to avoid slipping, the effect of stirring evenly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

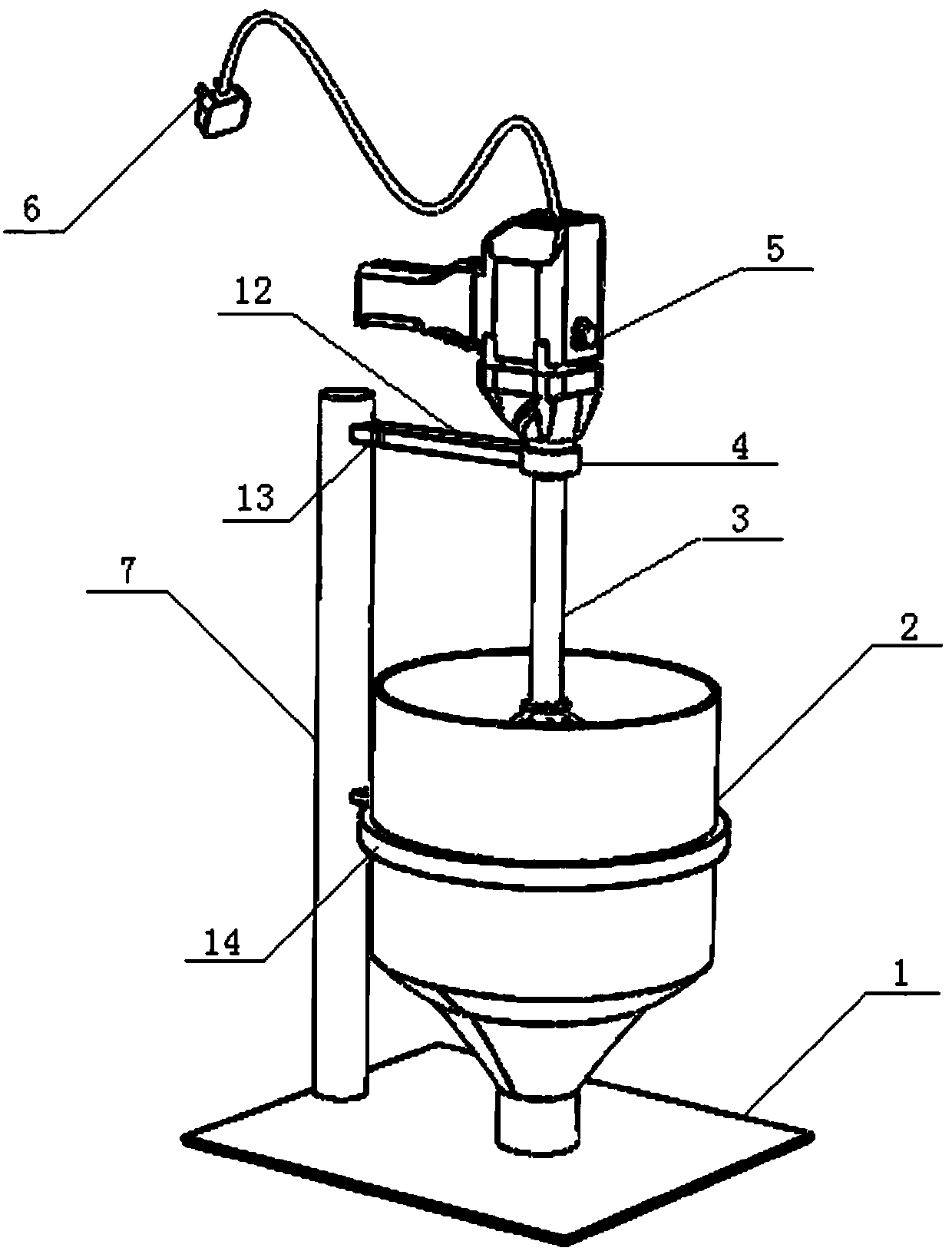

[0033] Before the start of the test, use the formula in soil mechanics to calculate the mass and moisture content of the soil samples that need to be configured, as well as the mass and moisture content of the undisturbed soil, and then calculate the mass of water that needs to be added. Weigh the soil sample and distilled water for later use.

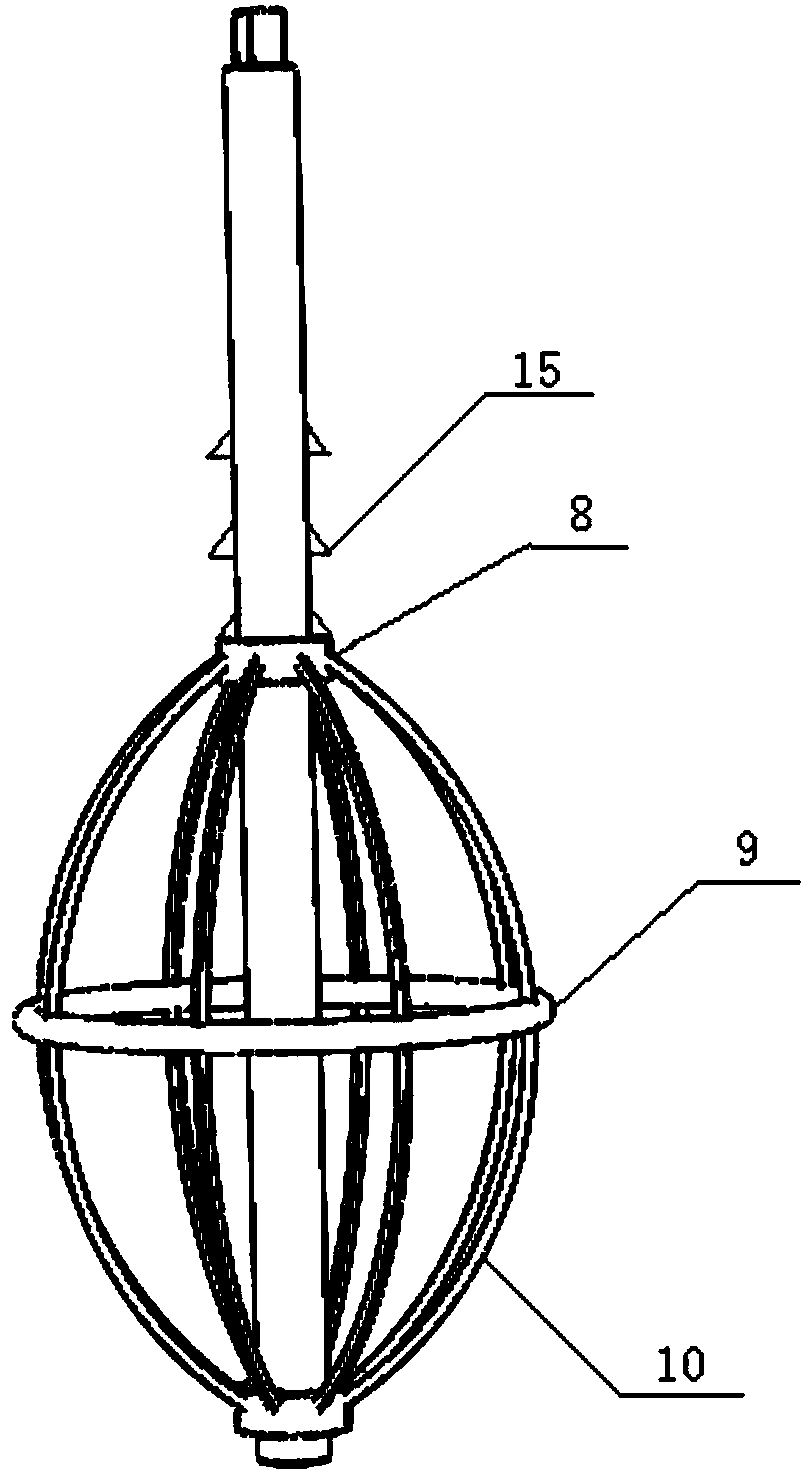

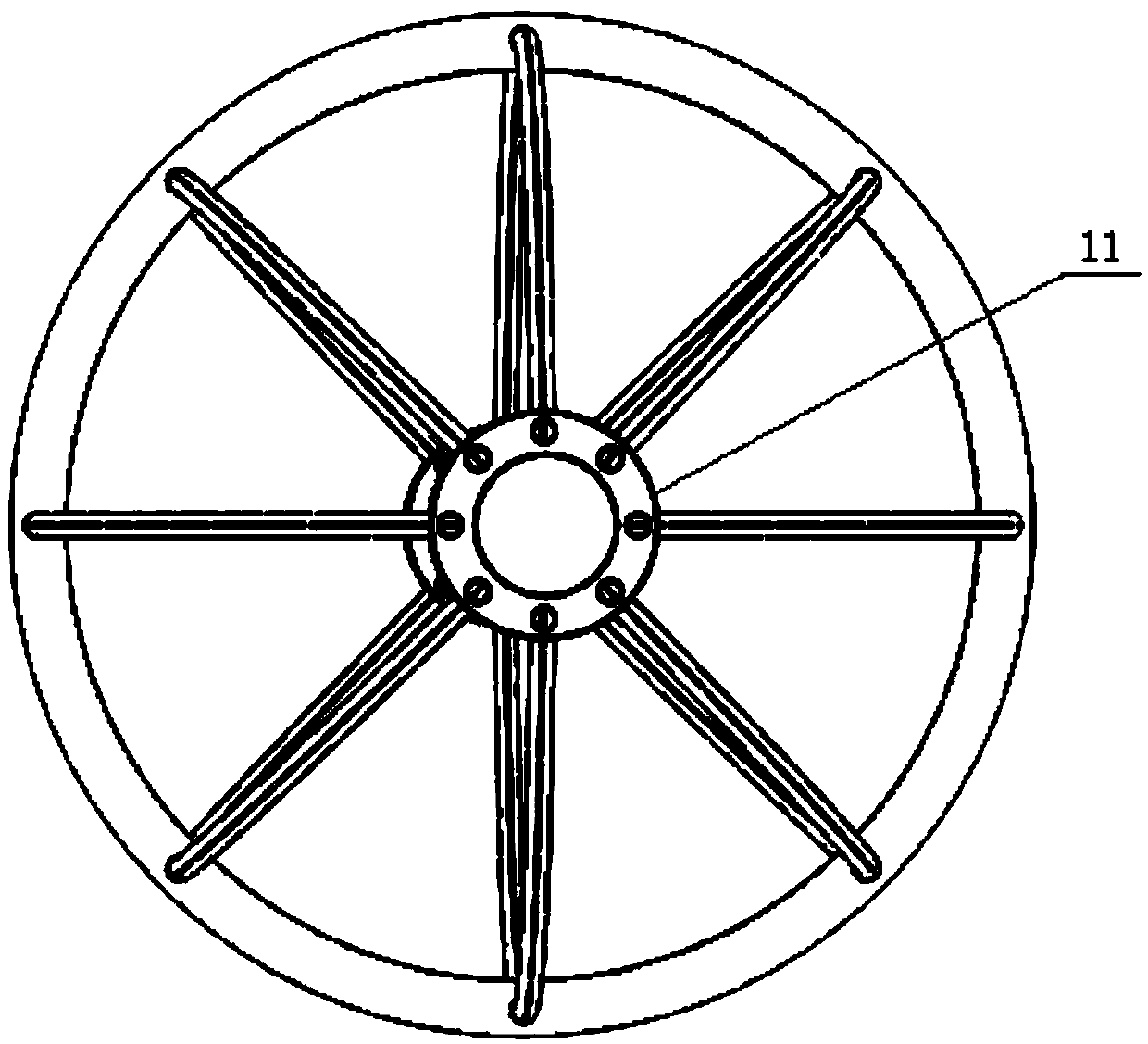

[0034] First, pour the weighed soil sample into the tank, then pour the weighed distilled water into the mixing tank, then remove the collar, move the movable flange, and adjust it to a position convenient for mixing. Insert the plug of the wire into the socket, turn on the switch, and start the stirring operation. After stirring at one position for 15-30 minutes, after the soil sample is stirred evenly, turn off the switch, then move the flange, and continue stirring at the second position.

[0035] After mixing the soil, close the switch, then pull out the plug, pour the soil in the mixing tank into the enamel bowl for later use, re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com