Profile segment and method for producing it

A bow-shaped piece and profile technology, which is applied in the direction of building components, building structures, door/window protection devices, etc., can solve the problems of troublesome heating at the connection position, poor accessibility, hindering implementation, etc., and achieve low-cost and reasonable manufacturing , Effective and economical manufacturing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

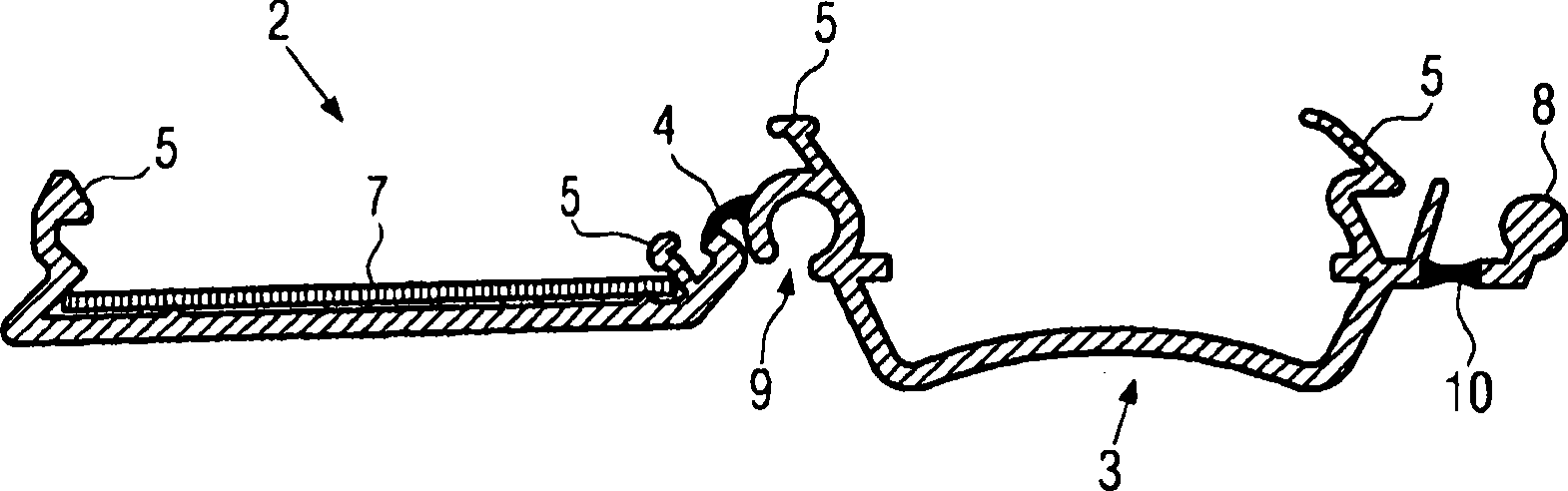

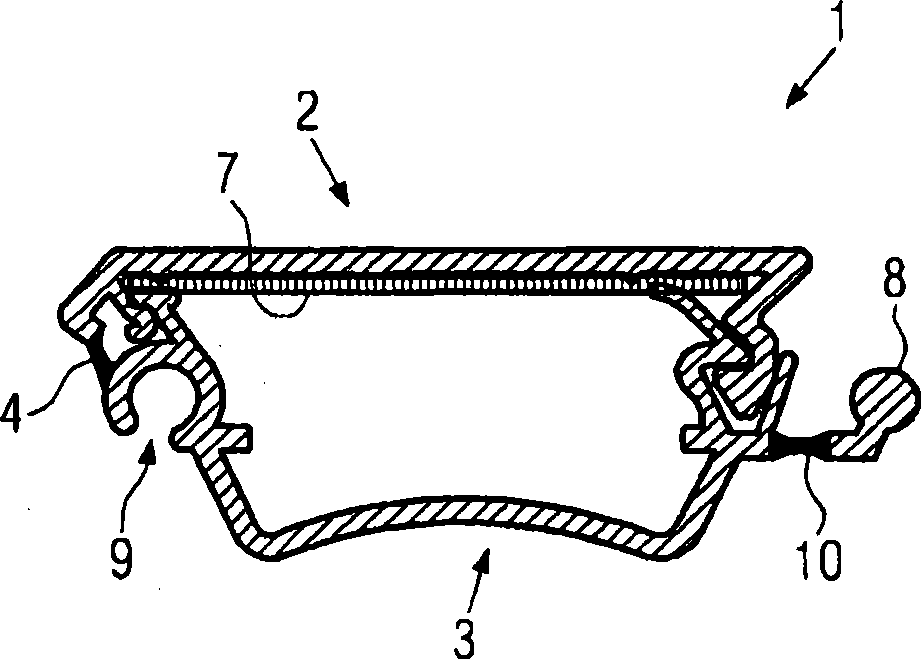

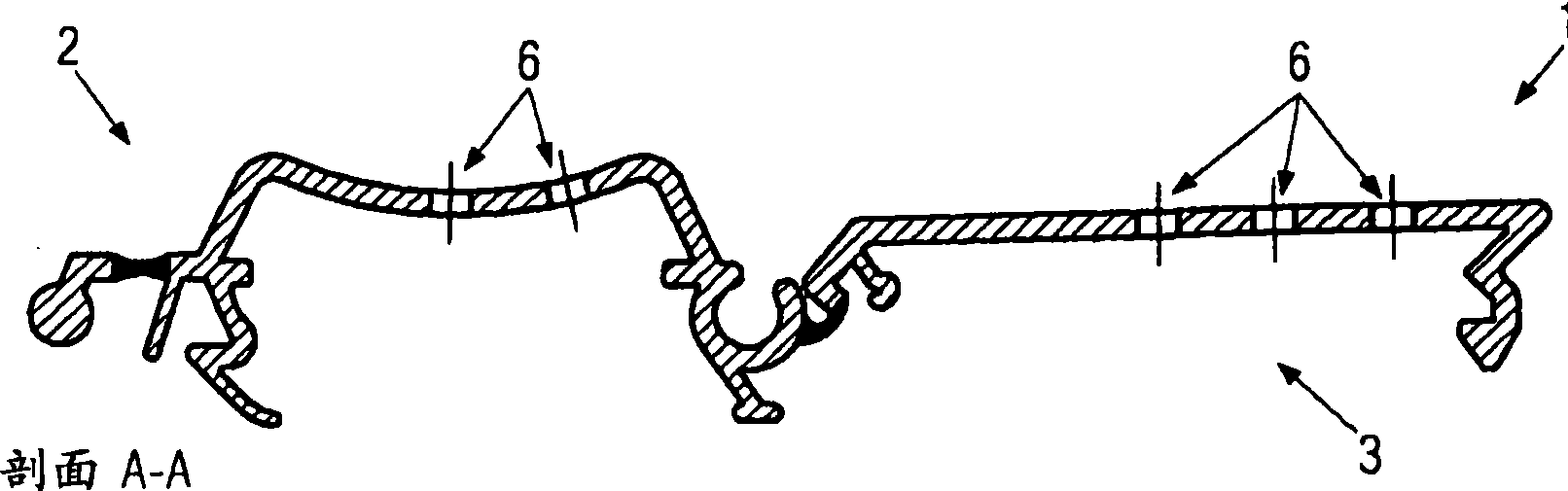

[0046] Figure 1a A cross-sectional view of an embodiment of the profile bracket according to the invention is shown in the unassembled state.

[0047] The profile bow 1 comprises two parts 2, 3 and a connecting device 4 connecting the two parts. Two of the parts 2, 3 are arranged side by side. Portions 2, 3 have substantially the same width, eg about 28mm. The wall thickness of the parts 2, 3 is substantially the same and is for example 1.3 mm. Other widths and wall thicknesses are also possible. Parts 2, 3 consist of plastic, preferably polypropylene or polyvinyl chloride. The connecting device 4, which acts as a soft hinge, is made of an elastomer or elastomer-like material, preferably polyurethane, soft polyvinyl chloride (PVC), silicone, rubber, a styrene-ethylene-butylene-styrene compound or A thermoplastically processable elastomeric composition. The parts 2 , 3 and the connecting device 4 are connected to one another in a materially bonded manner. A form-fitting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com