Rolling bearing and supercharger using the same

A technology of rolling bearings and rolling elements, applied in the fields of superchargers and rolling bearings, can solve problems such as reducing the viscosity of lubricating oil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

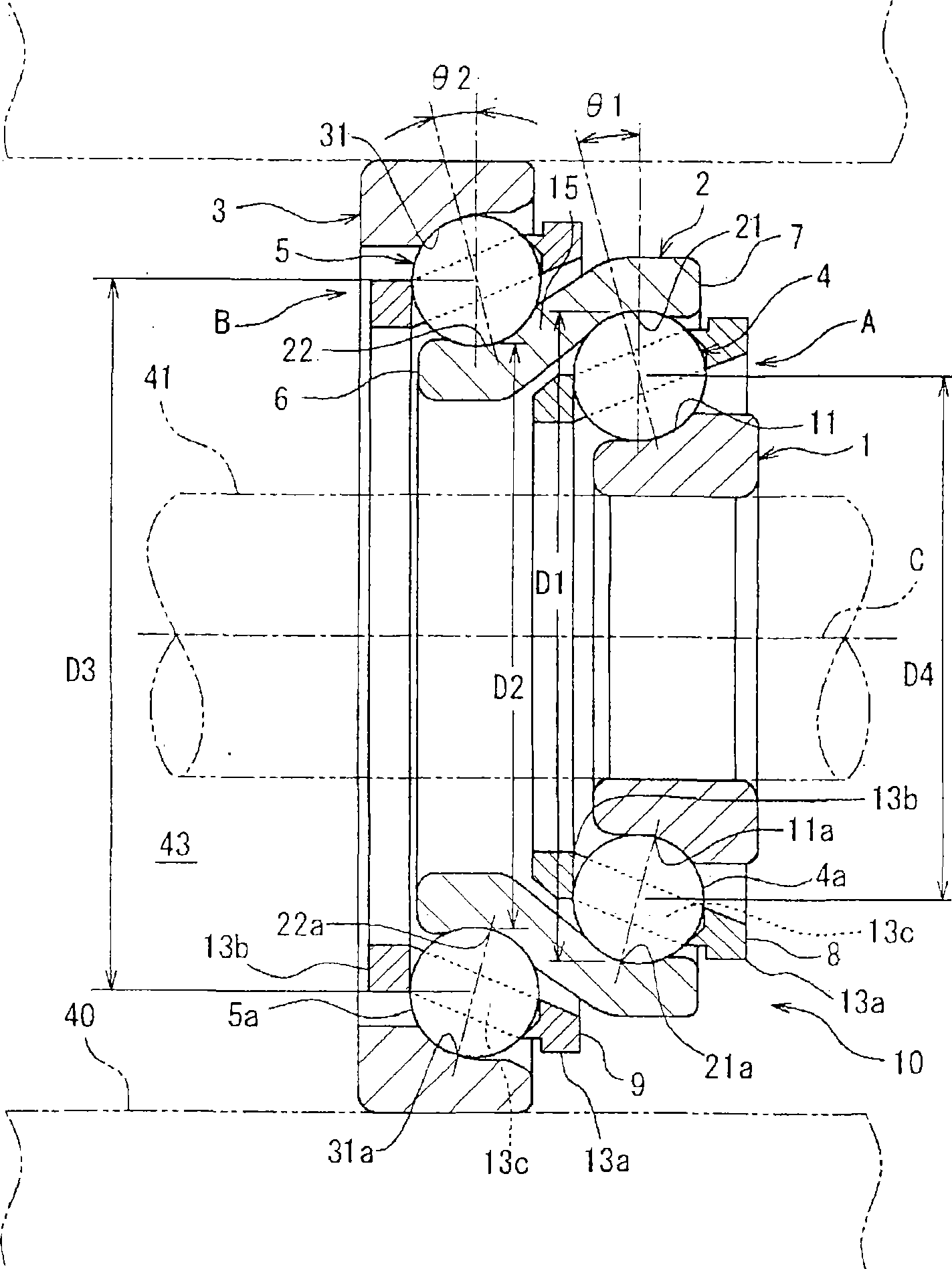

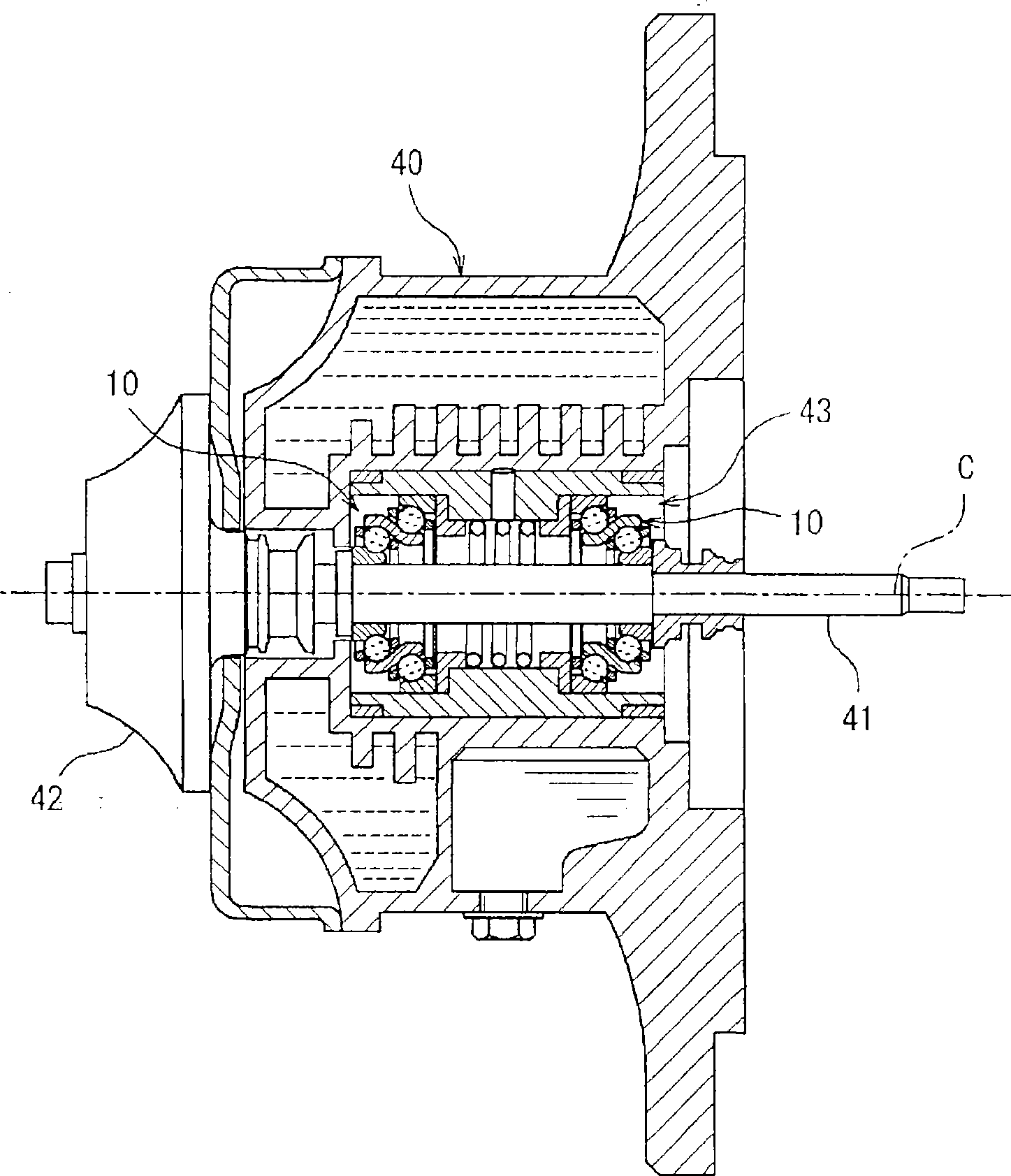

[0049] figure 1 is a sectional view showing a first embodiment of the rolling bearing of the present invention. The rolling bearing 10 rotatably supports a rotating shaft 41 in a center hole 43 formed in the housing 40 . image 3 A device in which such a rolling bearing 10 is used is shown in , for example a turbocharger used as a supercharger for an automobile engine. in the image 3 , the rolling bearings 10 are arranged in two rows in a spaced relation to each other in the direction of the axis C.

[0050] exist image 3 Among them, the turbocharger includes a casing 40 and a turbine shaft 41 supported in a central hole 43 of the casing 40 through the above rolling bearing 10 . The turbine shaft 41 has a turbine 42 mounted on one end portion thereof. The rolling bearing 10 supports the turbine shaft 41 such that the turbine shaft can rotate about the axis C.

[0051] exist figure 1 Among them, this rolling bearing 10 includes a separate inner ring 1 fitted on a turbin...

no. 2 example

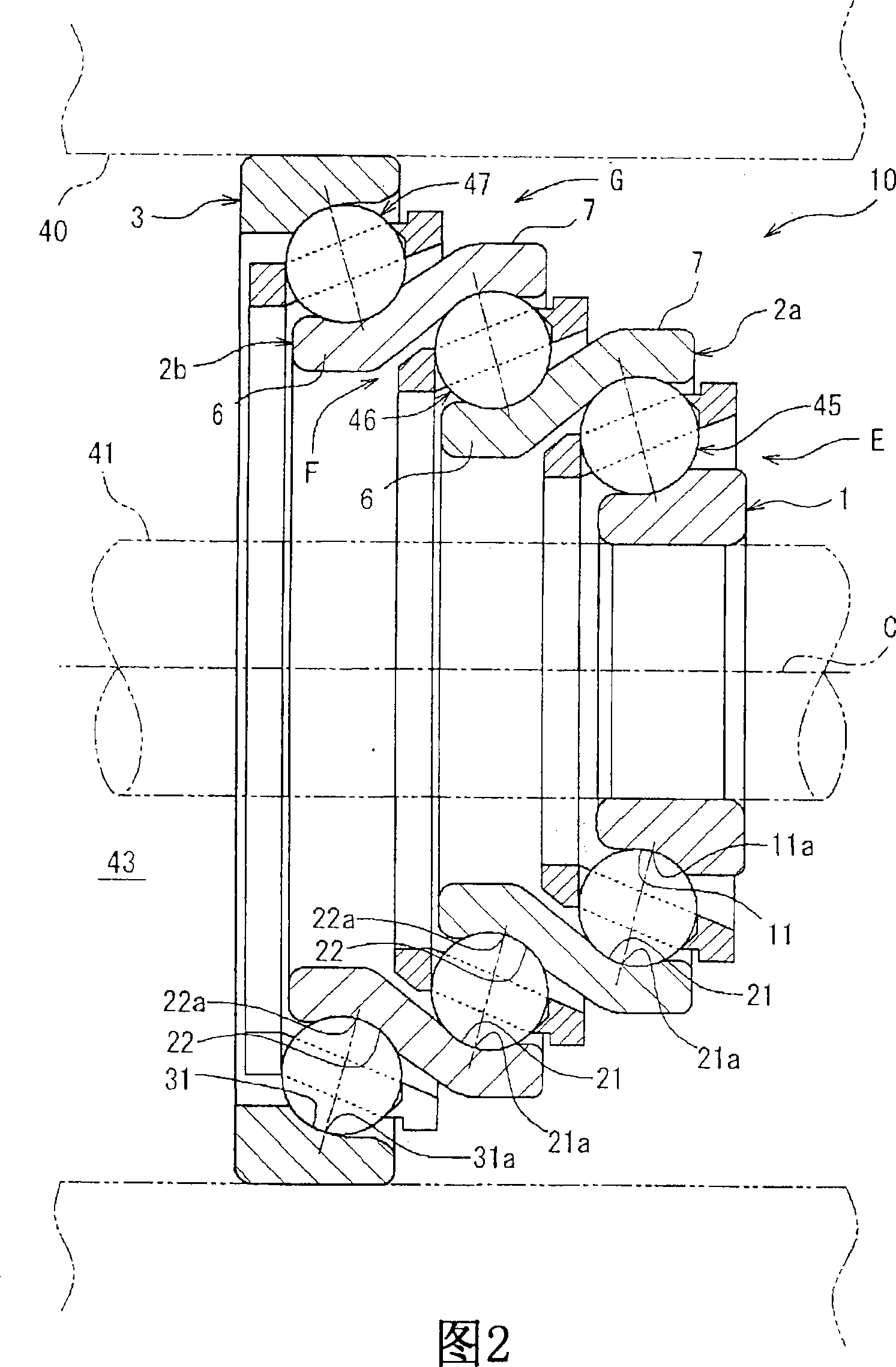

[0085] This embodiment differs from the first embodiment in that the diameter of the second ball serving as the rolling body is smaller than the diameter of the first ball serving as the rolling body. In the following description, the same configurations as those of the first embodiment will be designated by the same reference numerals, respectively, and their explanations will be omitted.

[0086] In the second embodiment, as in Figure 8 As shown in , the diameter d2 of the second ball 5 ′ arranged radially inside the intermediate ring 2 is smaller than the diameter d1 of the first ball 4 ′ arranged radially outside the intermediate ring 2 (d2

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com