New drive mode of straight channel type vibration machine and drive structure thereof

A technology of transmission structure and vibrating machine, which is applied in the direction of vibrating fluid and grain processing, etc. It can solve the problems of torsional vibration of the tank body, easy damage of the vibration motor, large torque of the tank body, etc., and achieve the requirement of reducing rigidity and reducing the implementation cost , The effect of stable vibration conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

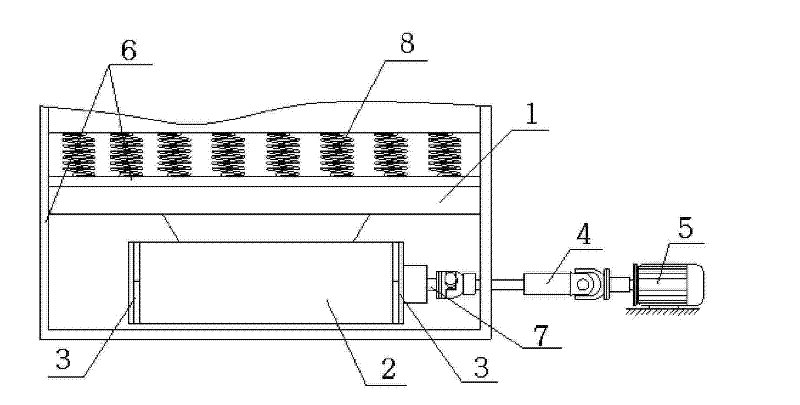

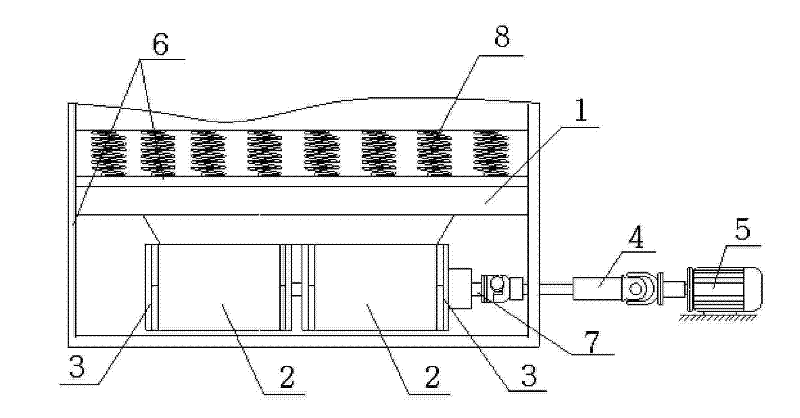

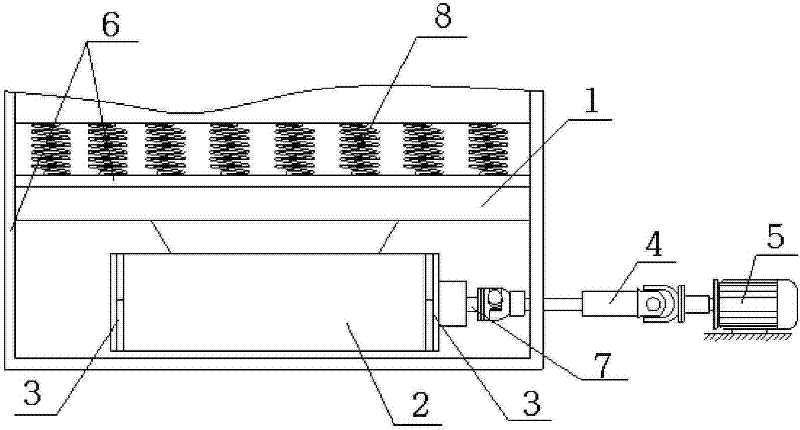

[0011] The embodiment of the present invention: a novel transmission method of a straight slot type vibrating machine, which drives the universal coupling through a motor, and the universal coupling drives the eccentric wheel shaft and the eccentric block group in the bearing seat at the bottom of the tank. Make the vibrator tank vibrate regularly.

[0012] The transmission structure made according to the new transmission method of the straight groove type vibrating machine: figure 1 As shown, the entire vibrating machine is placed on the working ground through the vibrating machine base 6, and the bearing seat 2 is connected under the trough body 1 of the straight groove vibrating machine; the bearing seat 2 is installed with an eccentric wheel shaft 7, and each end is installed with a set The eccentric wheel 3; the eccentric wheel shaft 7 is connected with the universal coupling 4; the other end of the universal coupling 4 is connected with the output shaft of the motor 5. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com