Suspension type production transmission line

A production line and hanging technology, applied in the direction of conveyors, mechanical conveyors, transportation and packaging, etc., can solve the problems of cumbersome installation, large space area, falling off, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The present invention will be further described below in conjunction with accompanying drawing.

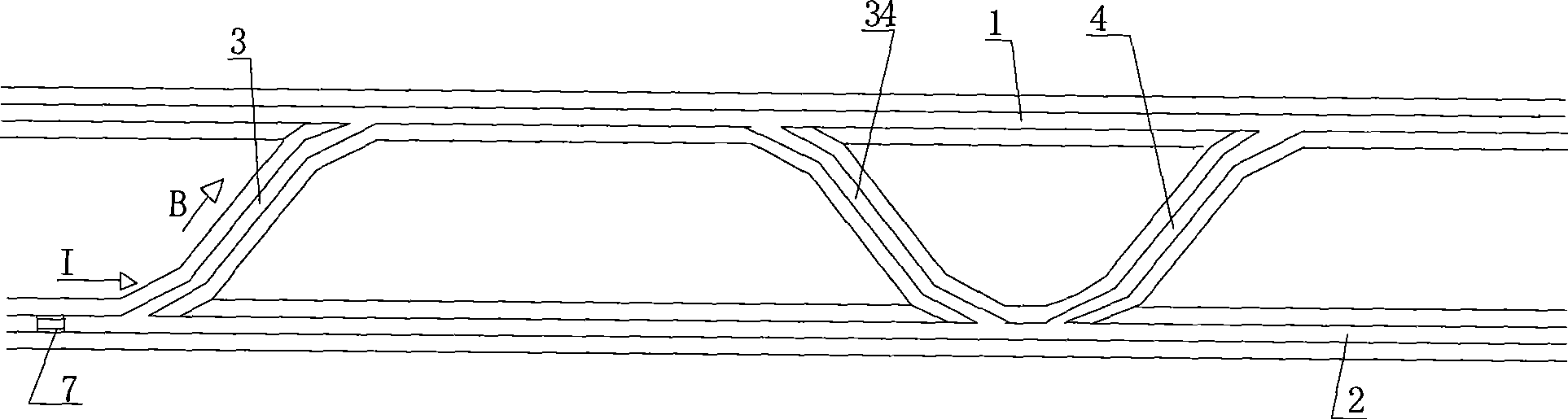

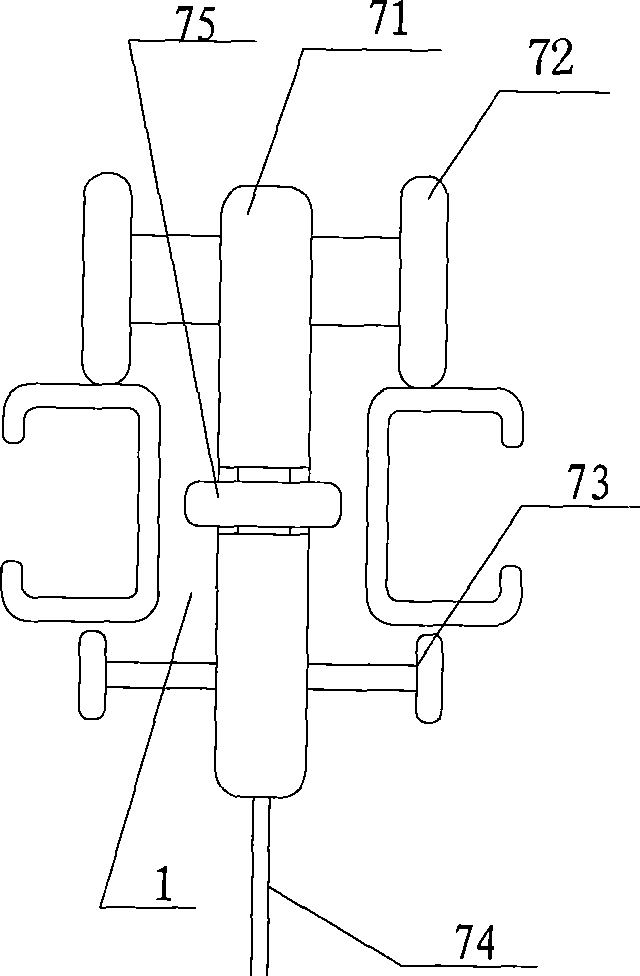

[0009] In order to solve the above technical problems, the present invention provides a hanging transmission production line, which is composed of at least one station section, each station section is composed of rails 1, 2, left rail 3 and right curved rail 4, and a conveyor 7, the rail 1 and 2 are C-shaped rails, curved rails 3 and 4 are rails connecting rails 1 and 2, and are fixed between rails 1 and 2. Curved rails 3 and 4 are arranged in a parallelogram, so that the conveyor 7 , 2. The transmission is convenient. In order to make the hanging type transmission production line of this structure easy to change direction and the transmission of clothes is smoother, a curved rail 34 is added between the curved rails 3 and 4 to make the curved rails in each station The rails are arranged in two trapezoidal shapes, one large and one small. When the conveyor 7 is transmitted ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com