Template for curved surface dry concrete construction

A technology of fair-faced concrete and formwork, which is applied in the field preparation and construction of formwork/formwork components and building components, can solve the problems of high cost, large one-time investment, and cannot be reused, and achieves low cost and high work efficiency. , the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

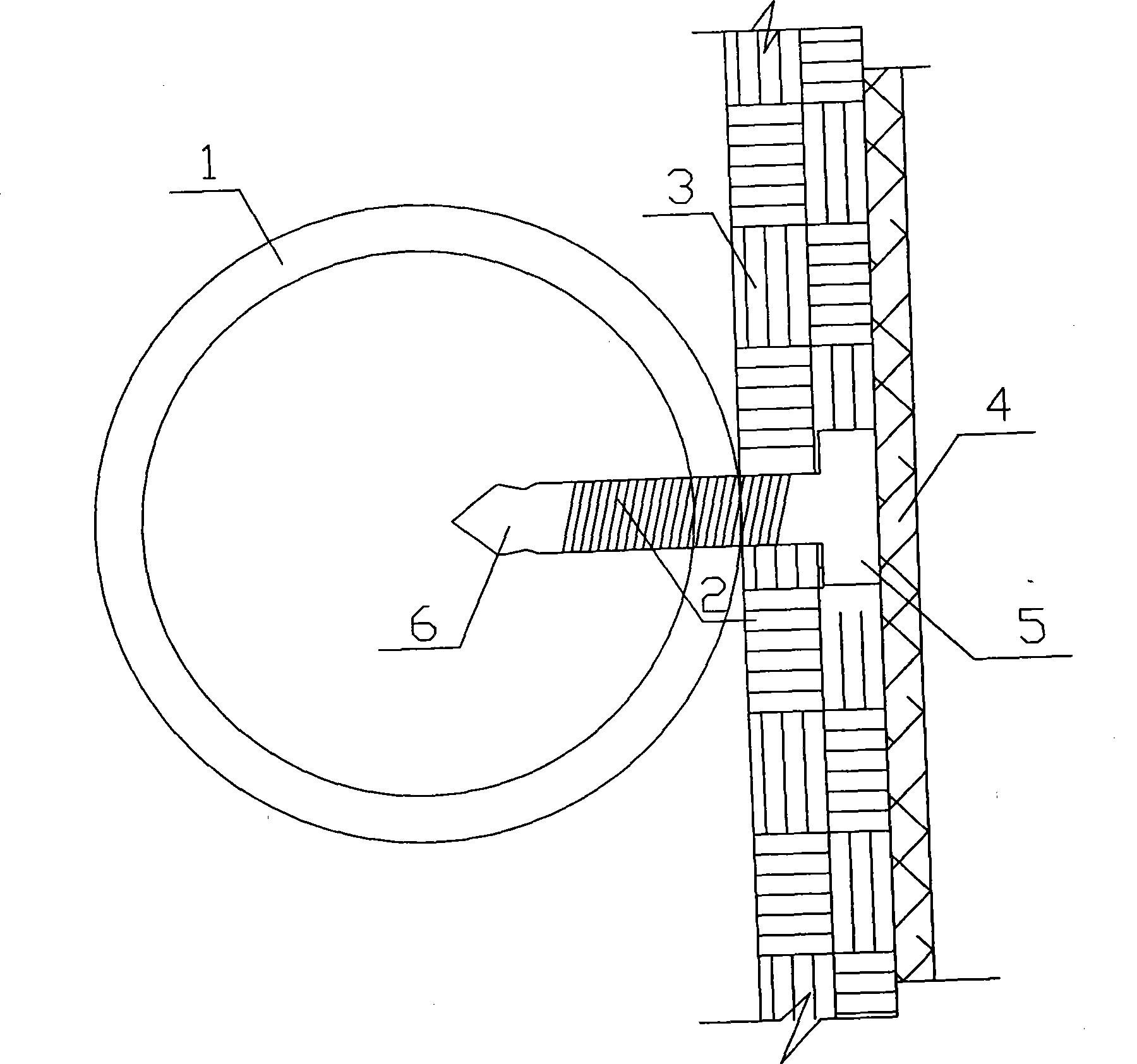

[0011] The specific embodiment of the present invention will be further described in conjunction with the accompanying drawings.

[0012] The formwork for curved surface fair-faced concrete construction is characterized in that it includes a steel pipe 1 on which a bamboo plywood 3 is fixed with self-tapping screws 2 , and self-tapping screw nuts 5 sink into the bamboo plywood 3 .

[0013] Fixed panel 4 on bamboo plywood 3.

[0014] Use self-tapping screws 2 to directly thread and drill holes on the steel pipe 1 to form threads on the pipe wall, and use self-tapping screws 2 to fix the bamboo plywood 3 on the steel pipe 1 to form a good support system and ensure no deformation. Self-tapping screw 2 drilling can be operated by special tools, which not only improves work efficiency, but also achieves good results. Afterwards, the panel 4 can be used according to the situation, and the panel 4 is fixed on the bamboo plywood 3 (bonded or nailed) to form a complete formwork system...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com