Electronic lock core with clutch device and electronic lock system therewith

A technology of an electronic lock system and a clutch device, applied in the field of electronic lock systems, can solve the problems of high maintenance cost, single key function and inability to apply, and achieve the effects of reducing maintenance cost, good anti-pick performance and high integration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0067] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments, but not as a limitation of the present invention.

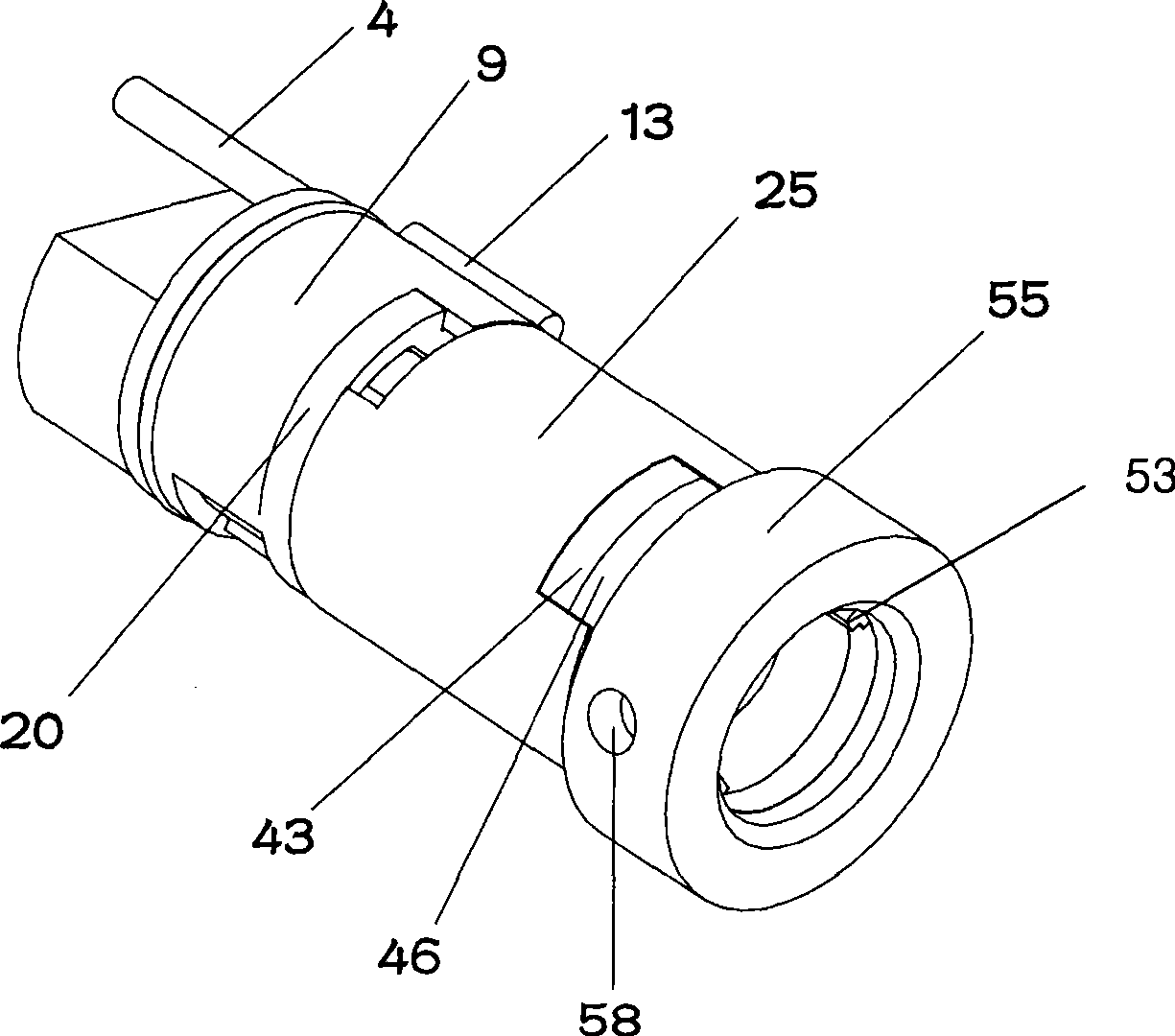

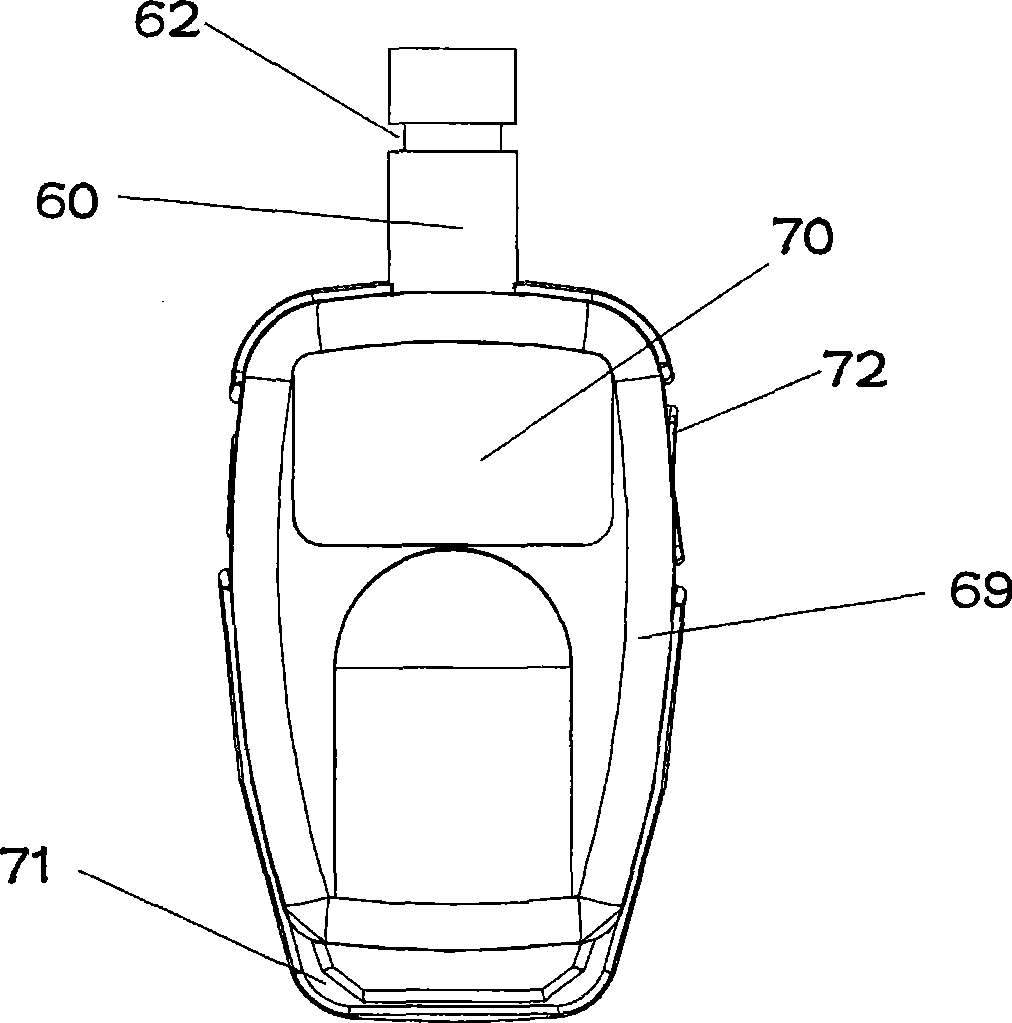

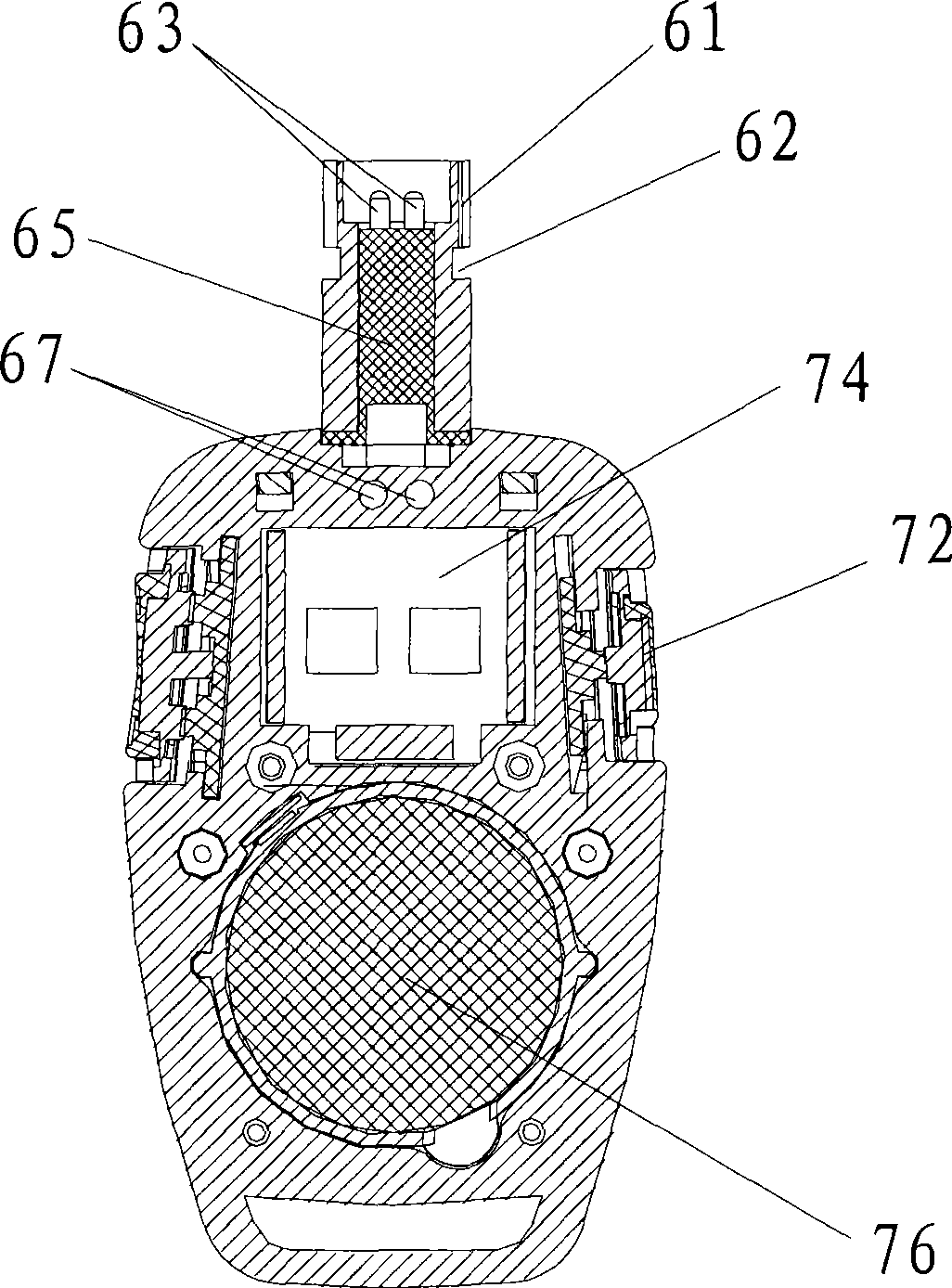

[0068] like figure 1 Shown is a schematic diagram of the overall structure of the combination of the components of the electronic lock cylinder of the present invention. The electronic lock cylinder is installed in the electronic lock cylinder installation hole 2 (combined with FIG. 6 ), and the mounting plate 55 is fixed on the On the lock housing 1, in the process of opening and closing the lock, the mounting disc 55 and the rotating clutch plate 51 do not rotate together with the electronic lock cylinder.

[0069] As shown in Figures 4 and 5, the electronic lock core includes a mechanical rotating core 9, a rotor 15, a clutch plate 20, an electronic rotating core 25, an electronic circuit device 34, an insulating sheet 41, a rotating disk 46, a rotating clutch plate 51 and The oute...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com