Indoor composite door

A technology of inner composite and door frame, which is applied in the field of indoor composite doors, can solve the problems of easy warping and deformation, no fire prevention, poor thermal insulation and sound insulation performance, etc., and achieve good fireproof performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

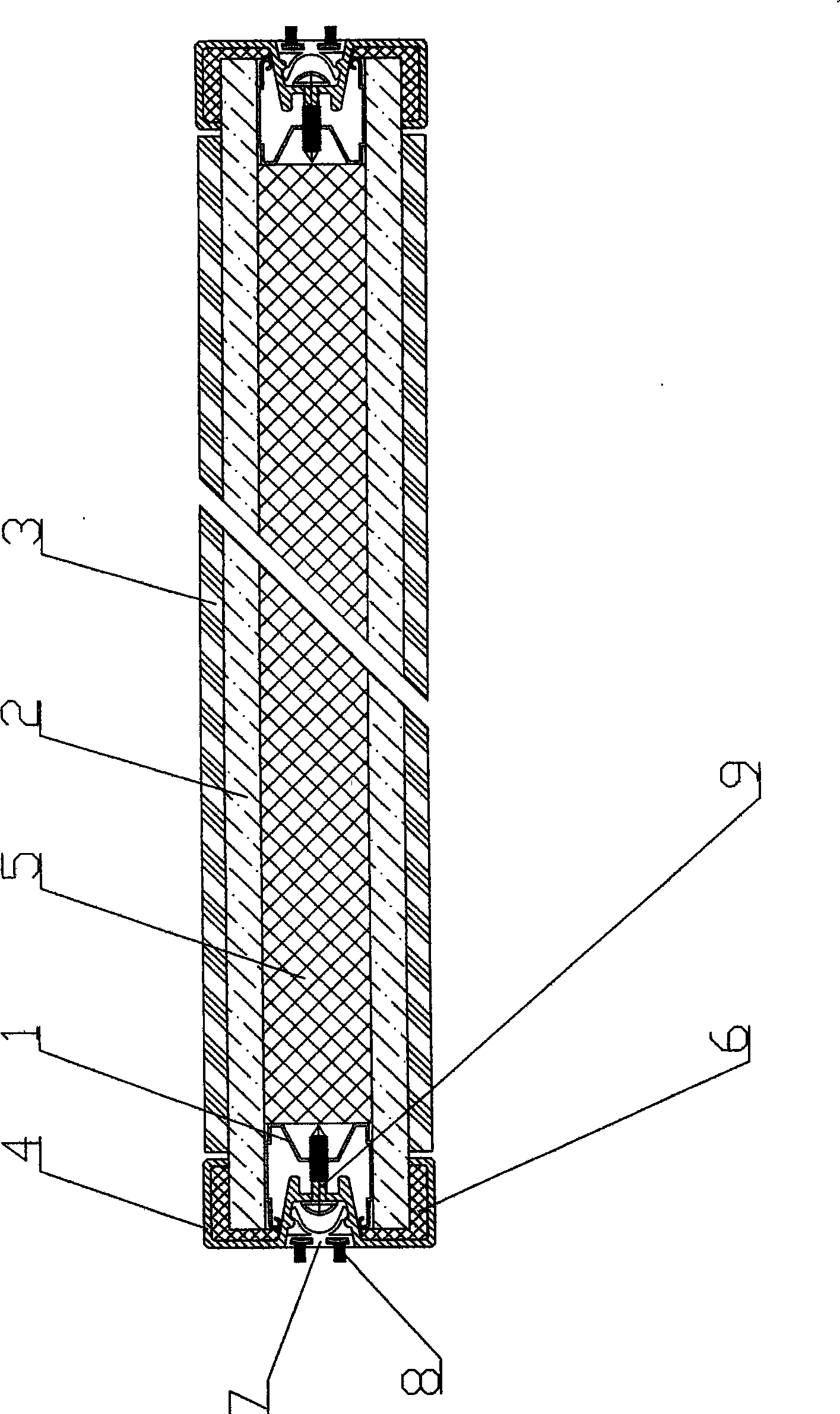

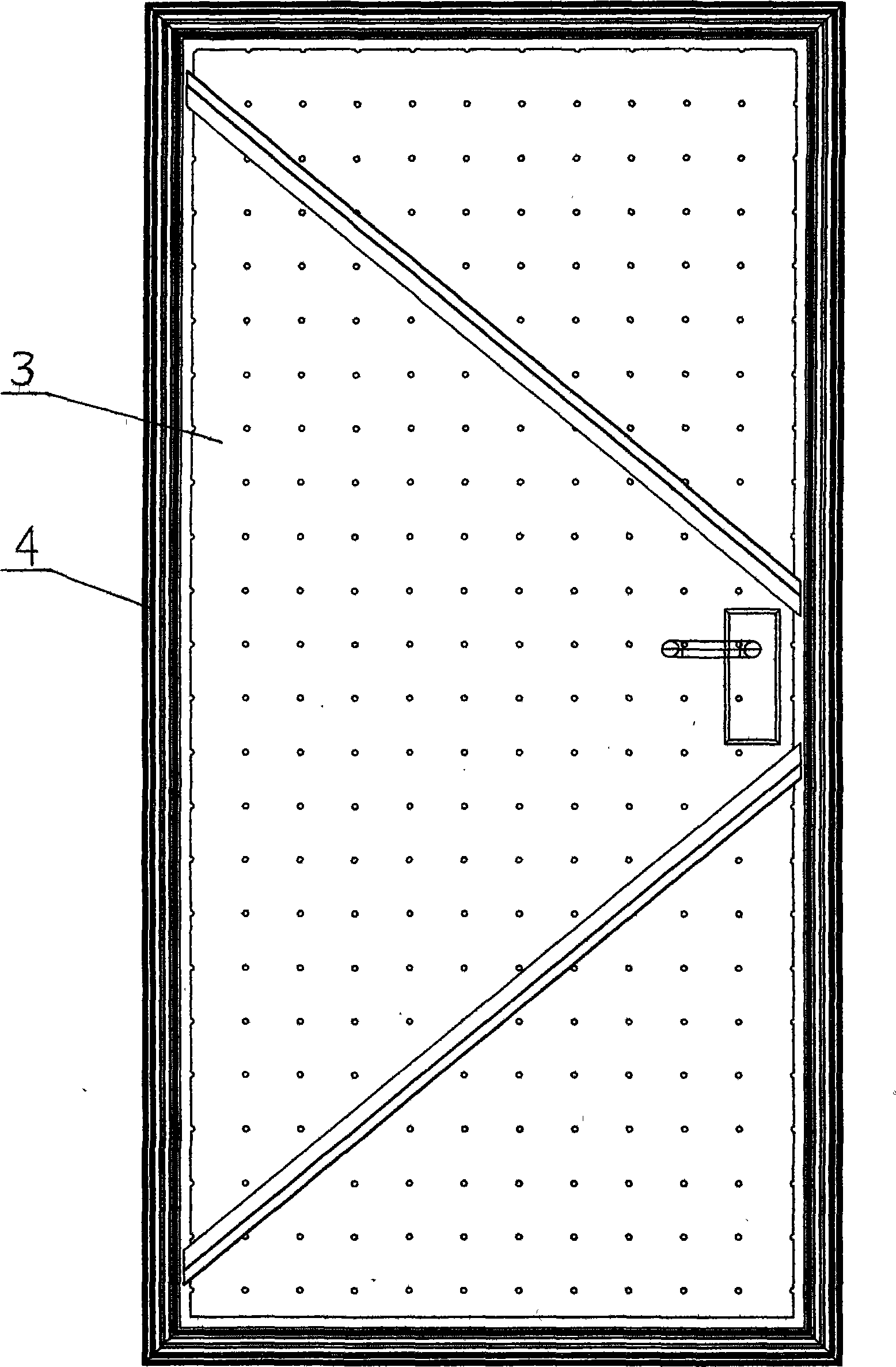

[0010] The indoor composite door of the present invention is realized in this way, and will be described in detail below in conjunction with the accompanying drawings. See figure 1 , figure 2 , the indoor composite door of the present invention is composed of: door frame 1, door bottom plate 2, door panel 3, door frame 4, filling body 5, edge strip 6, door frame bead 7, sealing top 8 and fastening nail 9, The door frame 1 made of light steel keel is sandwiched in parallel by two door bottom plates 2 made of plasterboard, and a filler 5 is installed in the middle, and the filler 5 is made of rock wool or glass wool and rubber The edge trim strip 6 wraps the peripheral edges of the door base plate 2. The door frame 4 made of aluminum alloy profiles is fixedly connected with the door frame 1 through metal fastening nails 9, and the door bottom plate 2 is fixed with the door frame 1 and the door frame 4 as a whole. The two door panels 3 are respectively pasted on the door bott...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap