Spherical hydraulic motor

A hydraulic motor, spherical technology, applied in the field of hydraulic motors, can solve the problems of poor sealing performance, fast wear of vane hydraulic motors, low specific power, etc., and achieve the effect of easy processing, compact structure and high power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

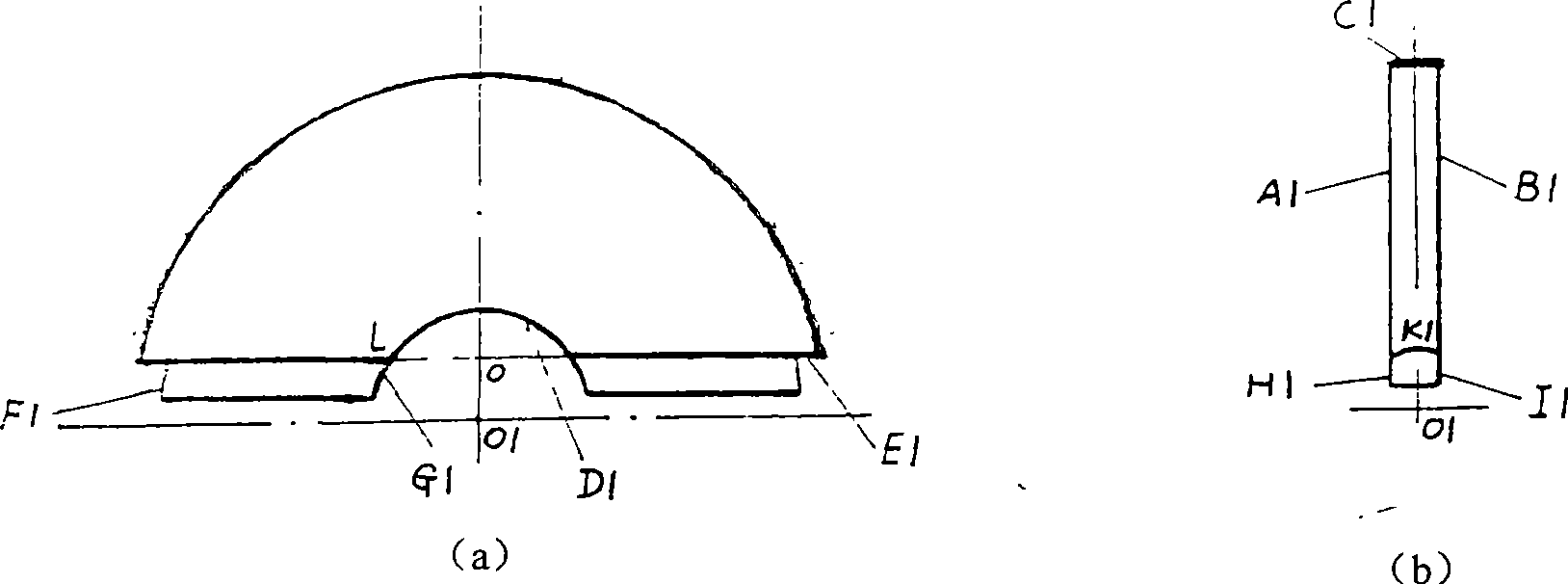

[0027] figure 1 a and figure 1 b shows the shape of the blade 3 and the sealing strip 4 of the present invention. The blade 3 is approximately semicircular, and has two identical pieces, wherein A1 and B1 are parallel planes, and the width of the blade 3 is the same as Figure 4 b The width of the hollow ring of shell 1 is equal, C1 is the cylinder whose center is O1 and the radius of E4 is the same as that of the cylinder of shell 1, D1 is the spherical surface whose center is O1 and the radius of C2 of the ball table of rotor 2 is the same, E1 is the cylinder Surface, the E1 cylindrical surface takes the symmetry axis passing through the center of the sphere O1 as the central axis, and takes O1K1 as the radius.

[0028] There are four identical sealing strips 4, one of which has a cylindrical surface with a radius equal to that of the blade 3 cylindrical surface E1 on the upper side, and a plane on the lower side, and the vertical distance between the spherical center O1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com