LCD cade-port gum dispersing device and method

A liquid crystal display and dispensing machine technology, which is applied to the surface coating liquid device, optics, instruments, etc., can solve the problems of unstable dispensing quality, high labor intensity of employees, and low production efficiency, and achieve dispensing The effect of stable quality, reducing labor intensity and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

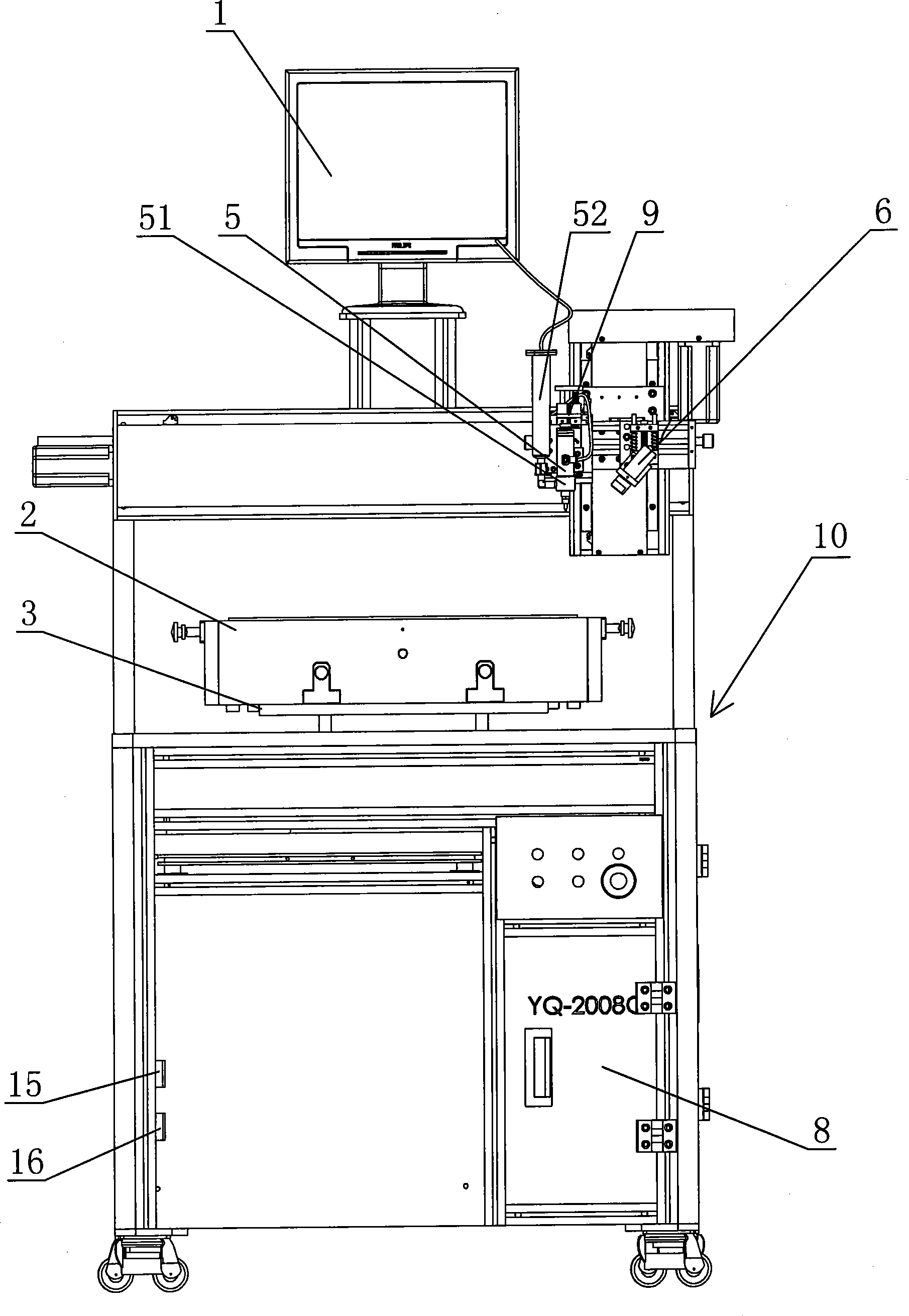

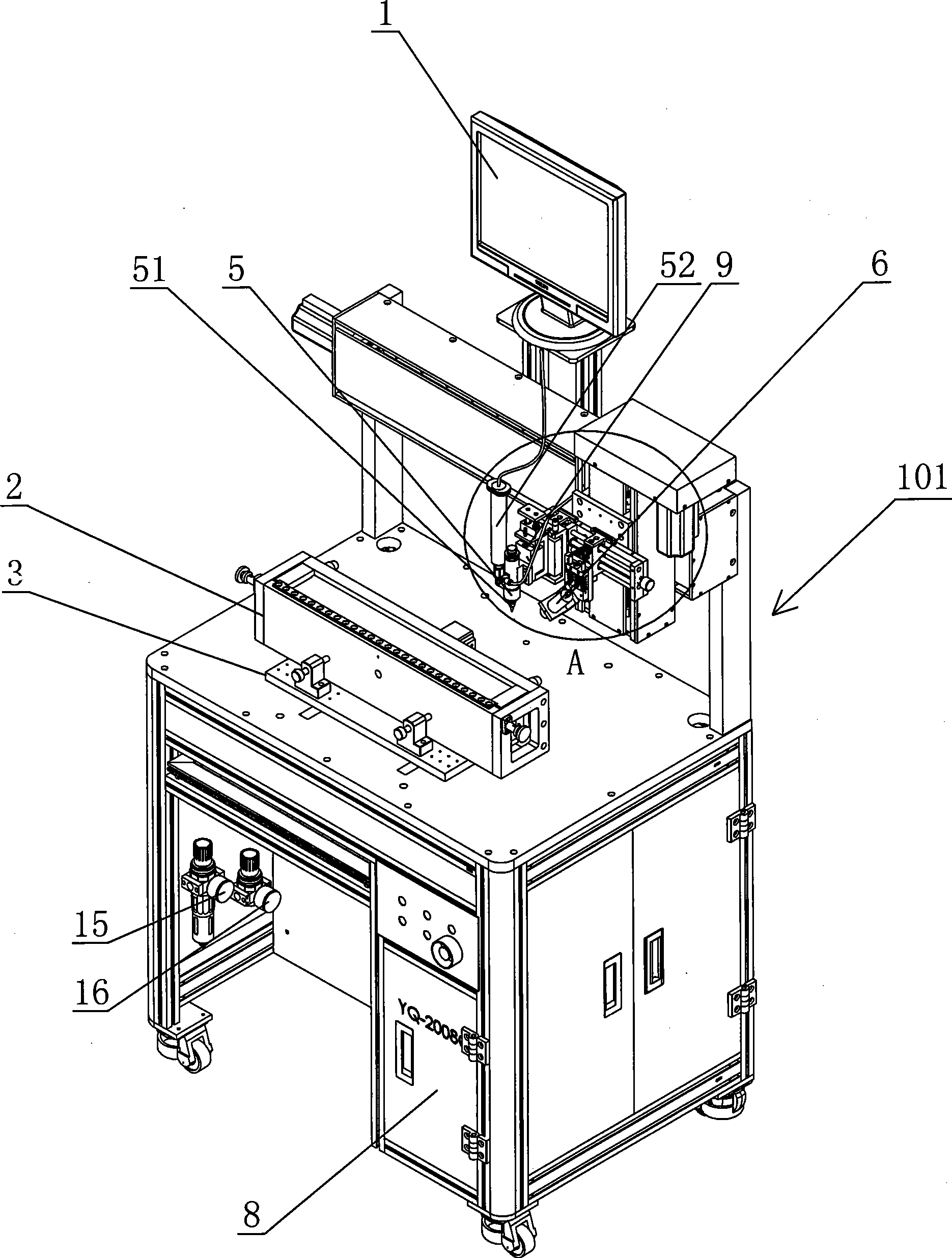

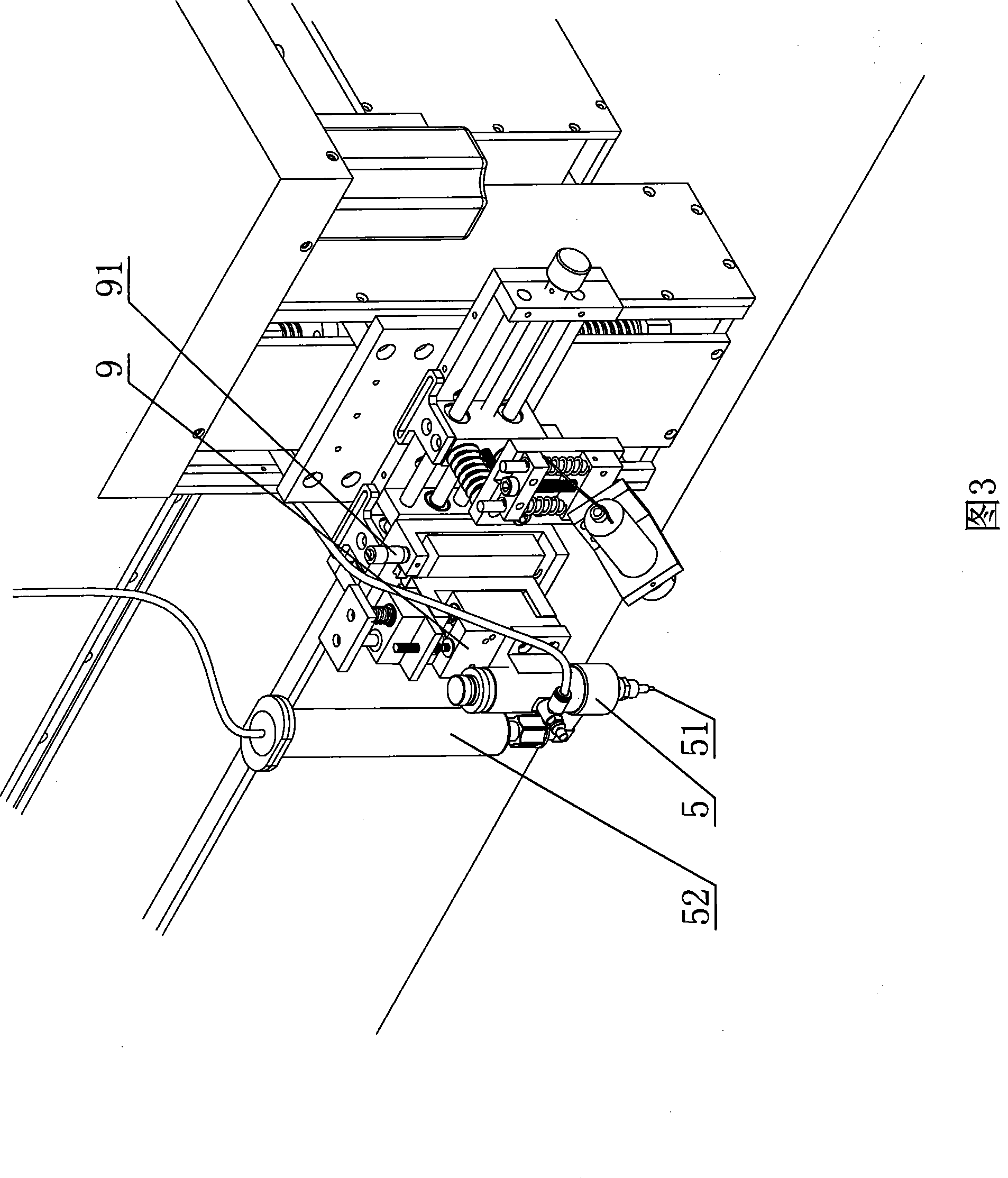

[0031] Such as Figure 1 to Figure 6 A liquid crystal display bottle dispenser shown includes a workbench 10, a glue dispensing platen 3, a glass fixture 2 for clamping glass, and a control host 8. The workbench 10 has a main body and a vertical (Z direction) The vertical frame 101 installed on the main body, the dispensing platen 3 is located on the main body of the workbench 10, the glass fixture 2 is installed on the dispensing platen 3, and this embodiment also has a dispensing device and a device for controlling the movement of the dispensing device The transmission mechanism and the driving motor driving the transmission mechanism, the transmission mechanism is installed on the vertical frame 101, the dispensing device is installed on the transmission mechanism, and the dispensing device and the driving motor are respectively connected to the control host;

[0032] The dispensing device includes a dispensing needle valve 5, a height detector 9 and an adjusting screw 91 t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com