Method for preparing polyethylene/maleic anhydride melt grafting high condensing pre-mixed master batch

A technology of polyethylene grafting and maleic anhydride, applied in the field of preparation of highly concentrated premixed masterbatches

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

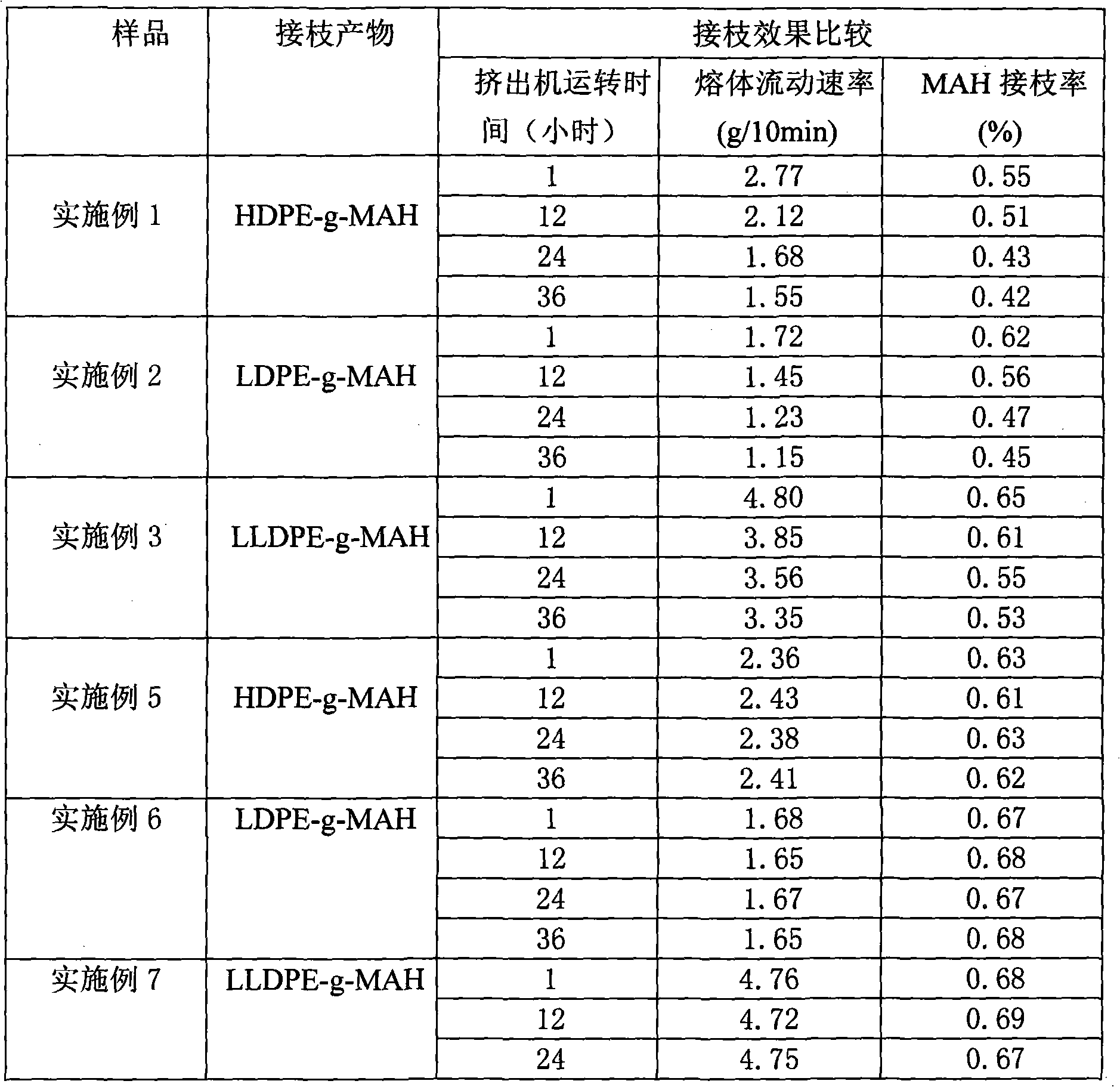

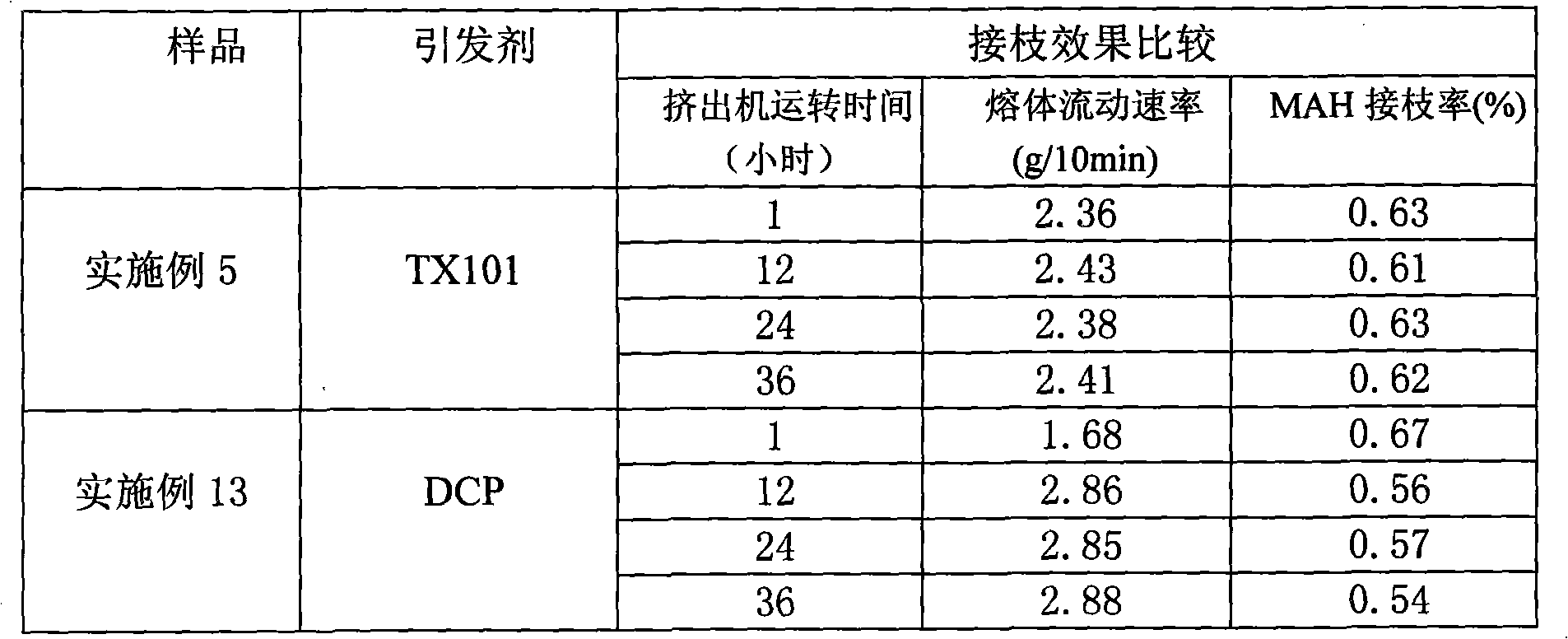

Examples

Embodiment 1

[0038] The preparation process is as follows: 100 parts of HDPE, 1.2 parts of MAH, 0.15 parts of initiator TX101, and 0.4 parts of antioxidant 1010 are weighed according to the proportion and directly mixed in a high-speed disperser. Then put it into the hopper of the twin-screw extruder for melt extrusion grafting. The temperature of each section of the twin-screw extruder is respectively: the temperature of zone I is 140°C, the temperature of zone II is 170°C, the temperature of zone III is 200°C, and the temperature of zone IV is 200°C , V zone temperature 210°C, head temperature 210°C, feed screw speed 30r / min, host screw speed 150r / min. The residence time of the material in the twin-screw extruder is 1.2 min. Then the grafted product is cooled and pelletized to obtain a high-density polyethylene grafted maleic anhydride product (HDPE-g-MAH).

[0039] Example 2:

Embodiment 2

[0041] Example 3:

Embodiment 3

[0043] Example 4:

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com