Spinneret orifice positioning and comprehensive detecting experimental apparatus for stainless steel wire rod production line

A technology of comprehensive testing and experimental equipment, applied in the direction of measuring equipment, testing of machine/structural components, instruments, etc., it can solve the problems of harsh environmental conditions on the production site, affecting the orderly production of production, and roller jamming.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

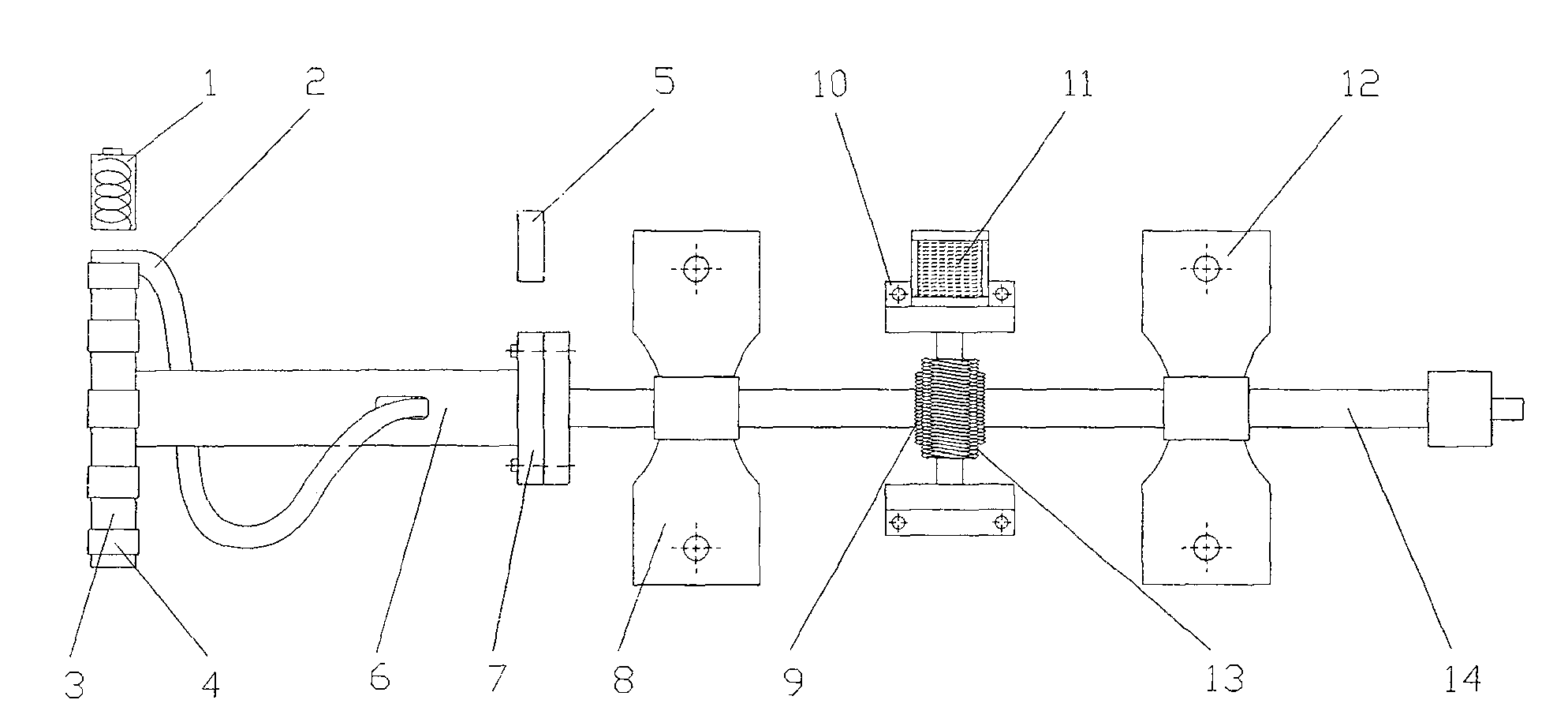

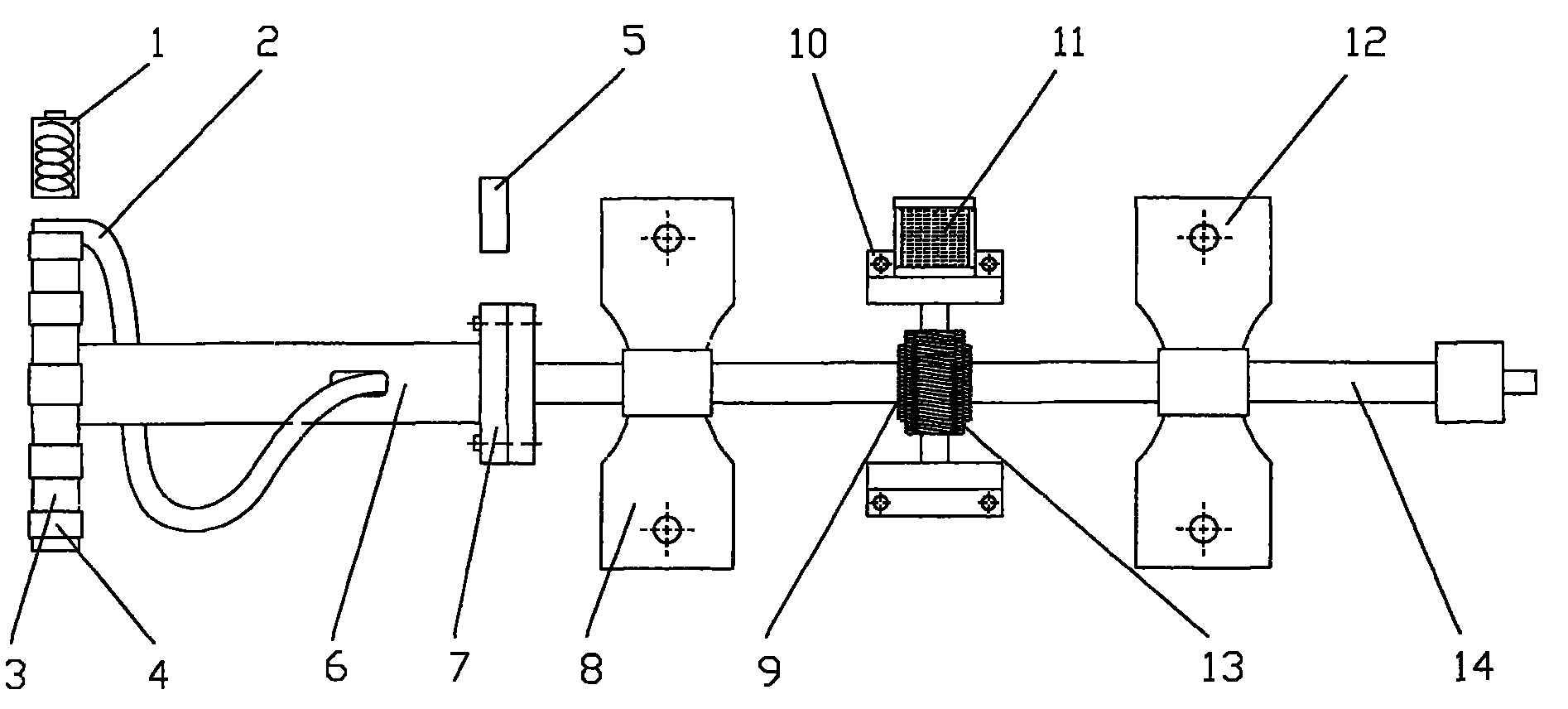

[0008] As shown in the attached figure, the comprehensive detection experiment device for the positioning of the spinning mouth of the stainless steel wire production line includes a magnetoelectric sensor 1, a spiral spinning tube 2, a circular flying disc 3, an L-shaped iron bracket 4, an optical fiber sensor 5, a hollow stainless steel tube 6, a stainless steel Flange 7, front spherical bearing supporting seat 8, worm rod 9, stepping motor supporting frame 10, stepping motor 11, rear spherical bearing supporting seat 12, turbine 13, hollow stainless steel main shaft 14, circular flying disc 3 and stainless steel pipe 6 One end is connected, the other end of the stainless steel pipe 6 is connected with the stainless steel flange 7, and one end of the spiral spinning pipe is fixed on the circular flying disc 3 through the iron bracket 4, and the hollow stainless steel main shaft 14 is sequentially provided with a front spherical bearing support seat 8, Turbine 13, rear spheric...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com