Light emitting module having heat radiation function, reflection cover and assembling method thereof

A light-emitting module and reflector technology, which is applied to electrical components, electrical solid-state devices, circuits, etc., can solve the problems of limited efficiency of heat dissipation pads and increase total material cost, and achieve simple heat dissipation design, improve heat dissipation efficiency, and reduce material costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

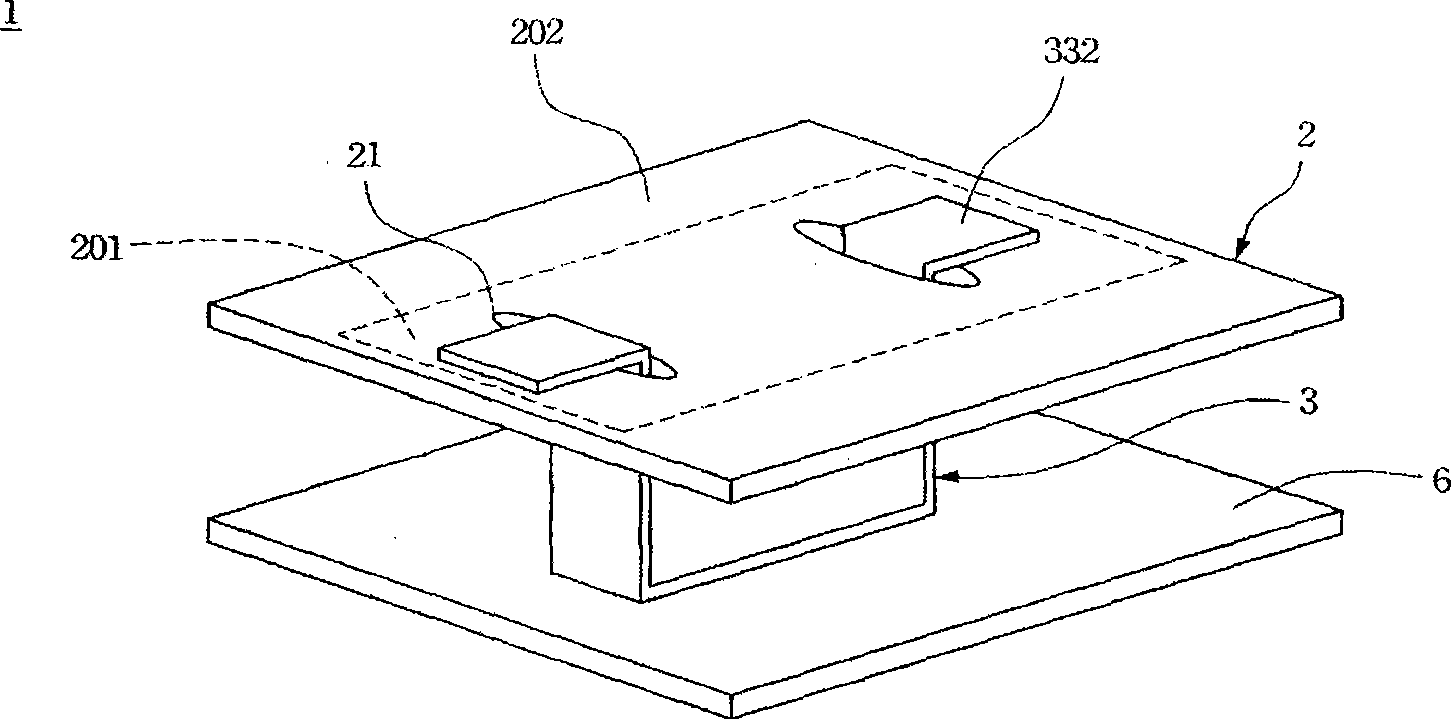

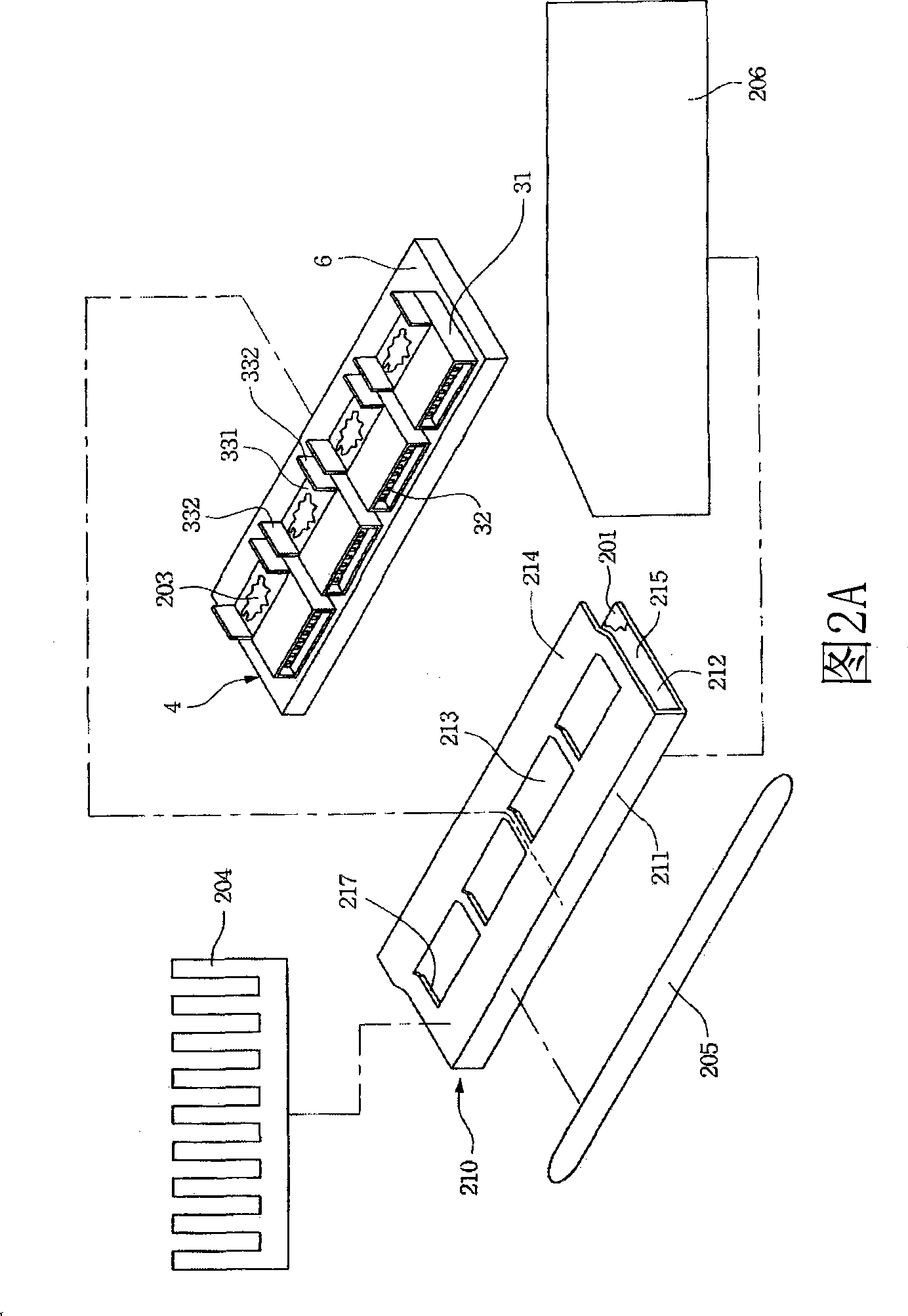

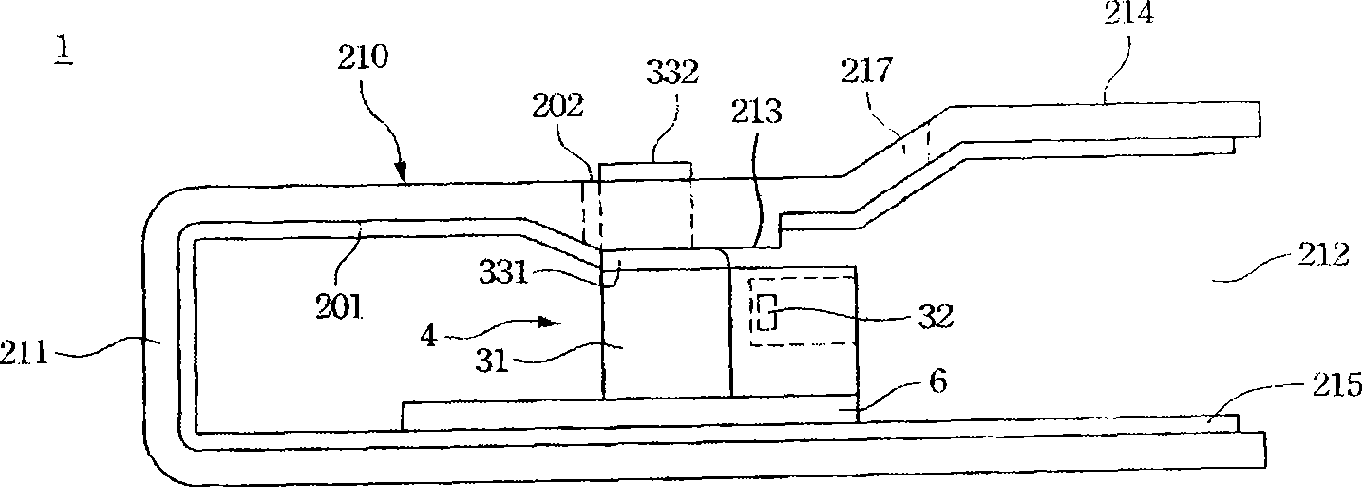

[0057] The invention discloses a light-emitting module with heat dissipation function and its assembly method, please refer to figure 1 as shown, figure 1 It is a schematic diagram of the light-emitting module of the present invention. Conceptually, the light emitting module 1 of the present invention at least includes a light emitting diode unit 3 , a heat sink 2 and a circuit board 6 . The LED unit 3 is located on the circuit board 6 and electrically connected to the circuit board 6 , and the LED unit 3 protrudes from at least one thermally conductive folded foot 332 . The heat sink 2 is provided with at least one opening 21 (such as the second opening 217 in FIG. 2A ). The light-emitting diode unit 3 extends the heat-conducting folded foot 332 out of the breach 21, so that the light-emitting diode unit 3 can contact the first surface 201 of the heat sink 2, and at the same time, one end of the heat-conducting folded foot 332 protruding out of the breach 21 can be bent Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com