Silicon microphone

A technology of silicon microphones and circuit boards, applied in the direction of electrostatic transducer microphones, semiconductor electrostatic transducers, etc., can solve the problems of increased cost, increased height of silicon microphone products, and difficult production, and achieve the effect of reduced manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

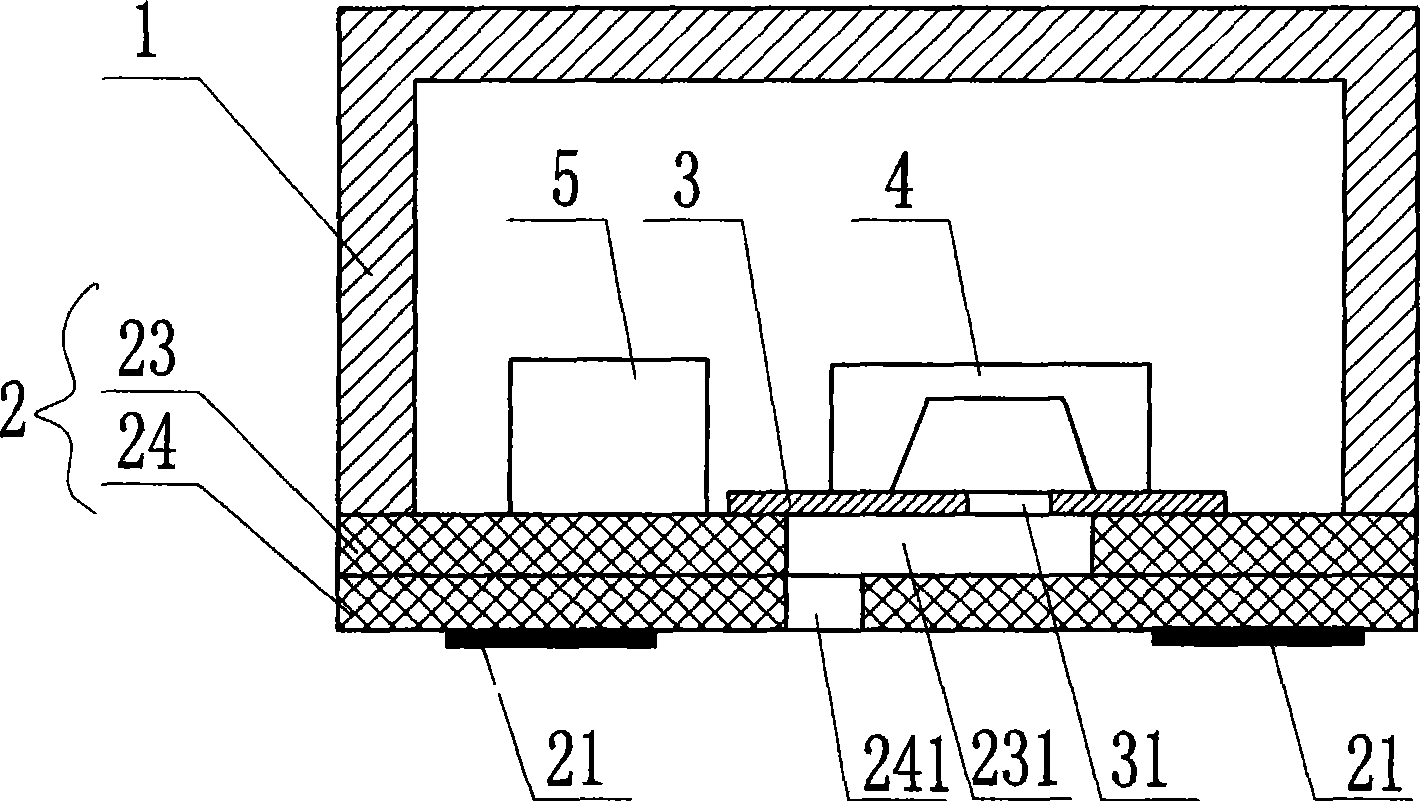

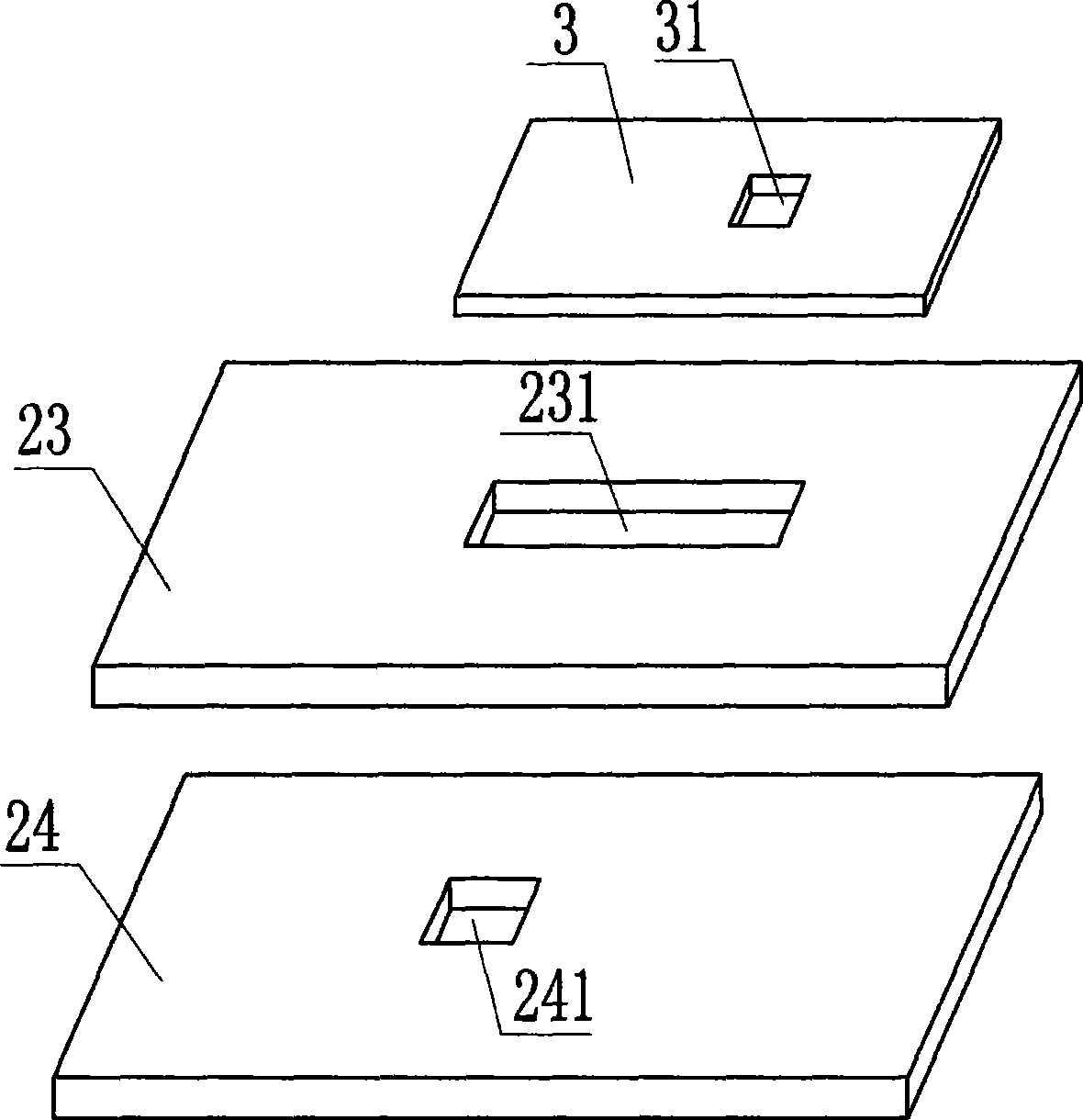

[0033] Embodiment one: if figure 1 , figure 2 As shown, the silicon microphone includes a square metal shell 1; a square circuit board 2 whose size is consistent with the plane size of the metal shell and uses resin material as the base material; the square metal shell 1 and the circuit board 2 are bonded together to form a square cavity , become the environmental protection structure of the silicon microphone; the outside of the circuit board 2 is provided with a plurality of external electrodes 21, and the electrodes 21 are used to solder and install the silicon microphone on the main circuit board of the electronic product, and transmit the electrical signal of the silicon microphone; the circuit board 2 includes Double-layer circuit board substrates 23 and 24, wherein the second layer of circuit board substrate 23 on the inside is provided with an elongated large-area second hollow 231, and the second hollow 231 is used as a sound middle channel; The first layer of circu...

Embodiment 2

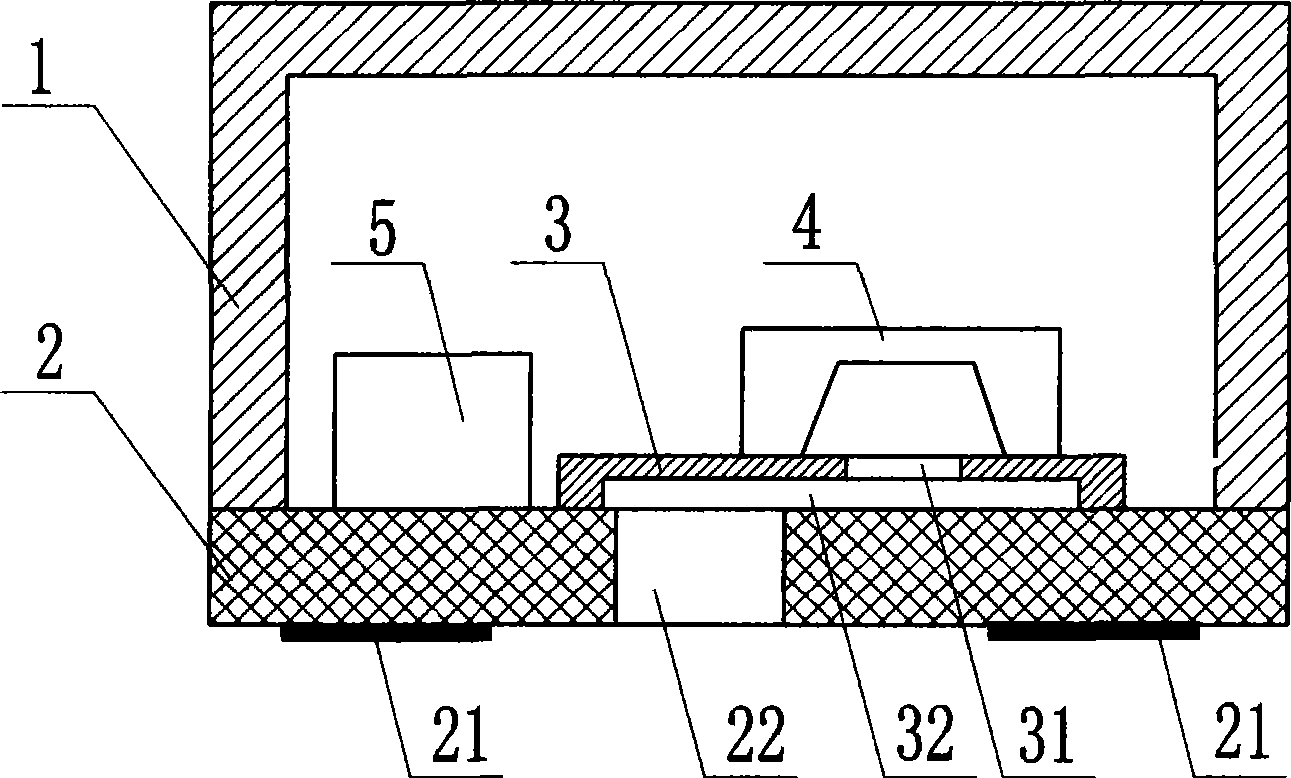

[0035] Embodiment two: if image 3 , Figure 4 shown, where Figure 4The dotted line indicates the position corresponding to the first acoustic hole 22 . Compared with the implementation case 1, this implementation case does not set the sound middle channel inside the circuit board, but sets the sound middle channel inside the sheet body 3 . The peripheral edge of the square piece 3 is provided with a bend towards one side of the circuit board 2, and the bent portion is bonded to the surface of the circuit board 2, so that a horizontal space 32 is formed between the sheet 3 and the surface of the circuit board 2 The vertical positions of the first sound hole 22 on the circuit board and the second sound hole 31 on the sheet body 3 do not correspond, and can communicate with each other through the horizontal space 32, so that the horizontal space 32 forms an elongated sound middle channel.

[0036] This implementation case can achieve an effect similar to that of the implemen...

Embodiment 3

[0038] Embodiment three: as Figure 8 , Figure 9 As shown, the first sound hole 22 on the circuit board 2 of the silicon microphone with this structure is a circular sound hole, and an annular sealing device 6 is arranged around the outside. This structure can make the Bottom-type silicon microphone installed on the main circuit board of electronic products, and the air tightness between the silicon microphone circuit board and the main circuit board of electronic products is good to prevent air leakage. A disc or a ring of glue.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com