Organic polluted soil thermal desorption system capable of not generating secondary pollution to environment

A technology of organic pollution and secondary pollution, applied in the field of organic polluted soil thermal desorption system, can solve the problems of surrounding environmental pollution, secondary pollution, entering the surrounding environment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

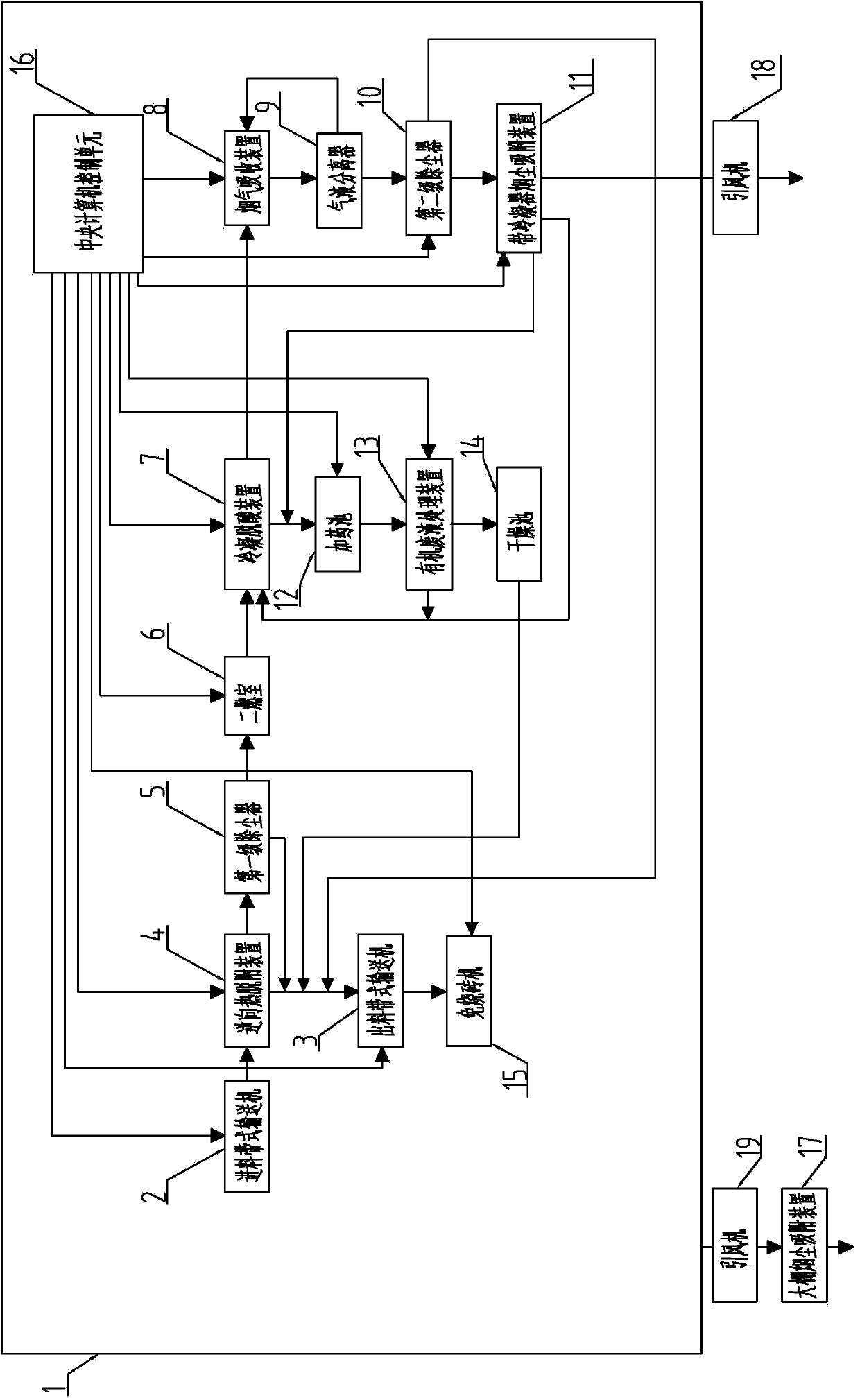

[0014] figure 1 It shows a thermal desorption system for organic polluted soil that does not cause secondary pollution to the environment, including a reverse thermal desorption device 4 for treating organic polluted soil and a first-stage dust collector whose flue gas outlet is sequentially connected through a flue gas pipeline 5. Secondary combustion chamber for high-temperature treatment of flue gas 6, condensation deacidification device 7, flue gas absorption device 8, gas-liquid separator 9, second-stage dust collector 10, smoke dust adsorption device with condenser 11 and the system that controls the operation of the entire system Central computer control unit 16 . The present invention is characterized in that the wastewater outlet of the condensation deacidification device 7 is connected to the water inlet of an organic wastewater treatment d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com