Surface treatment installation for metallic parts, particularly by electrolysis

A technology for processing equipment and metal components, which is applied to electrolytic components, electrolytic processes, electrodes, etc., and can solve problems such as damage to batch components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

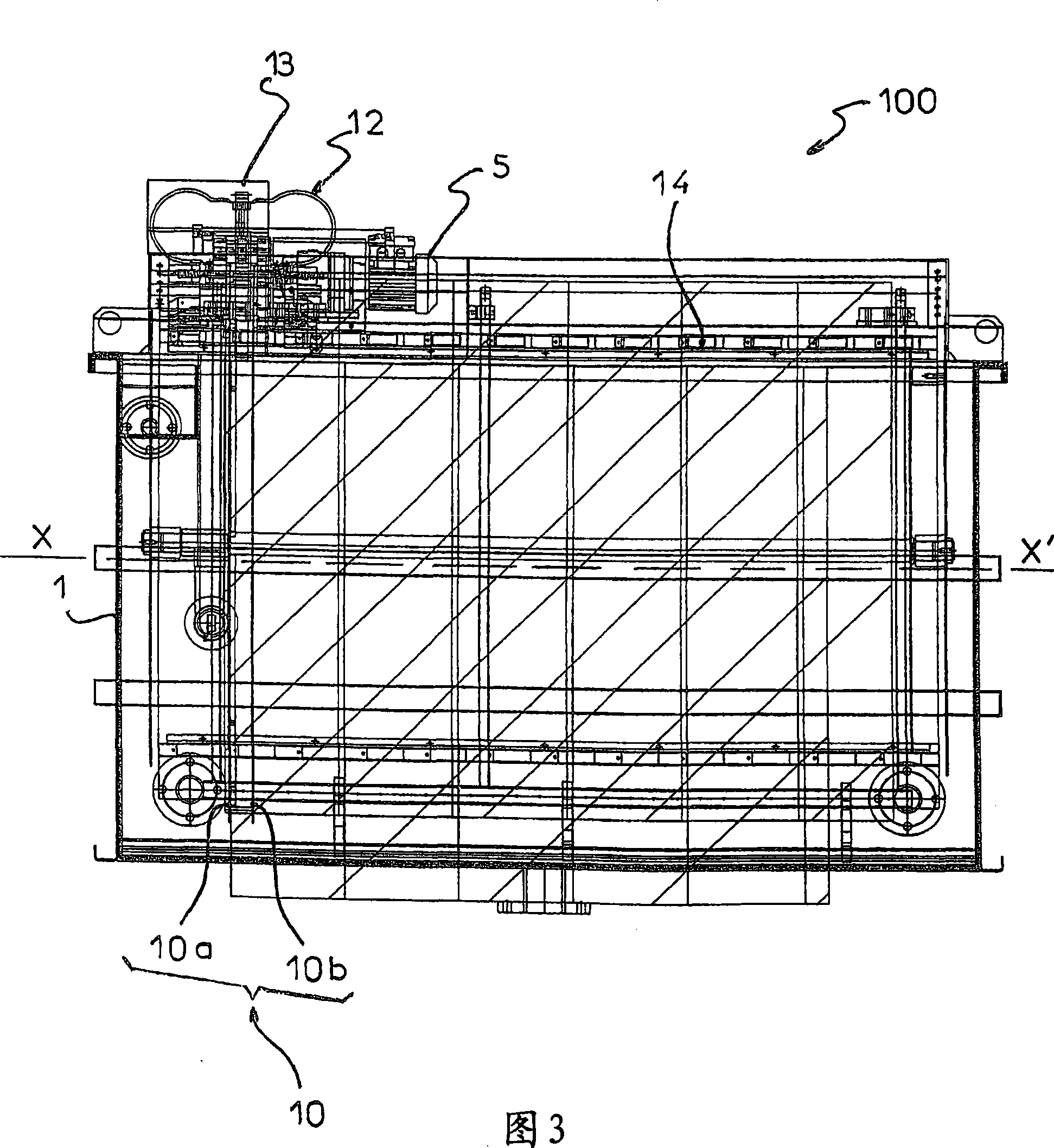

[0021] [21] According to the method of implementation of the treatment plant according to the invention, each member is immersed in the tank and subjected to at least a rotational movement, so that air bubbles that may have formed in the electrolytic cell are discharged from the inner wall of said member.

[0022] [22] According to the embodiment shown, each member is subjected to a rotational movement of at least 90°, preferably 360°.

[0023] [23] According to the embodiment shown, a defined number of said components is placed beforehand on a support or box 4 having at least one retainer for each of said components. mechanism.

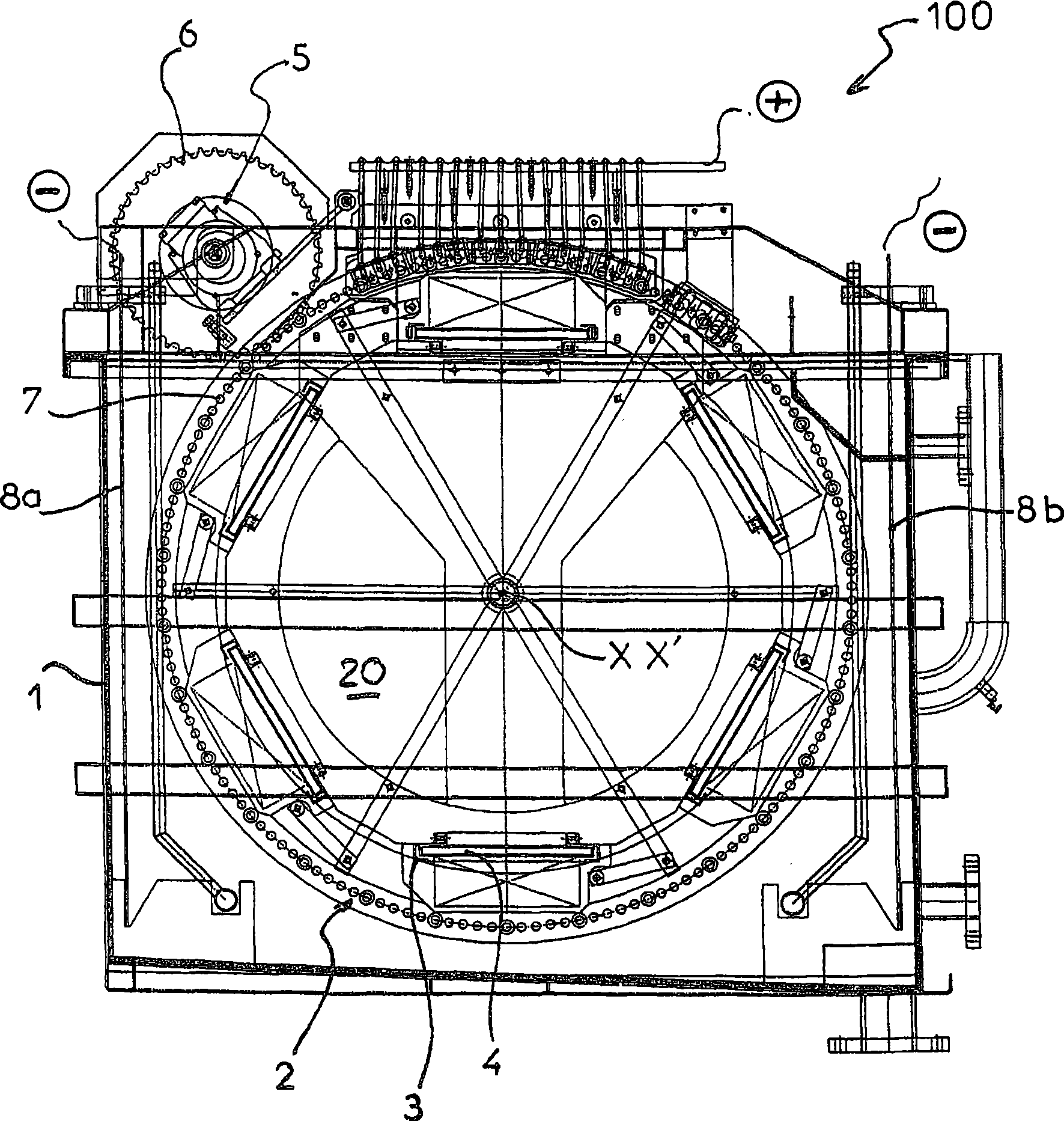

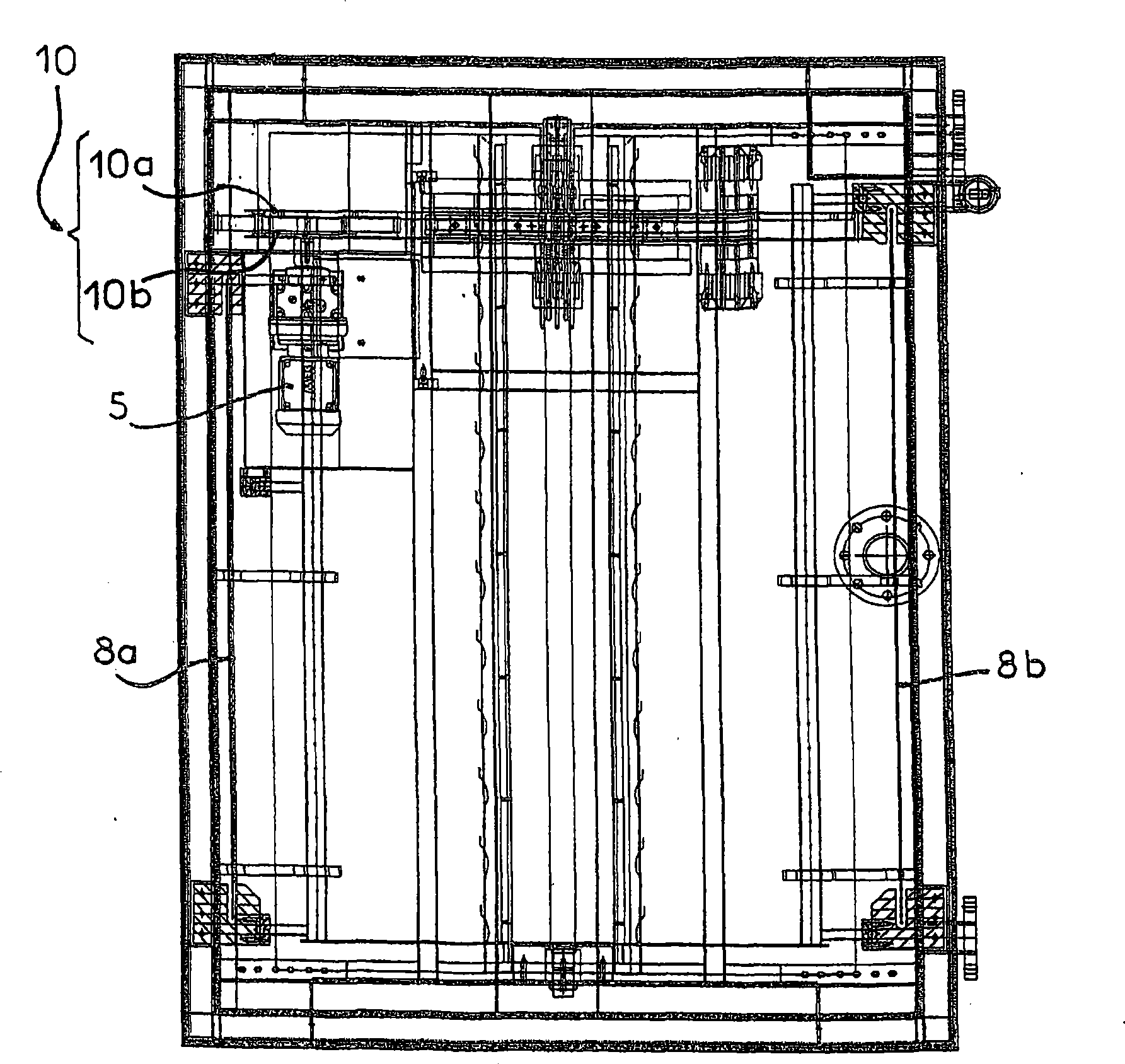

[0024] [24] According to this embodiment, the component treatment plant bearing the general reference numeral 100 comprises a tank 1 having a drum 2 inside the tank 1 along a horizontal axis X, X 'rotatably mounted, the component to be treated is fixed on said drum 2.

[0025] [25] According to the embodiment shown, the drum 2 has on its outer peri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com