Clutch unit

A technology of clutches and side clutches, applied in the direction of clutches, one-way clutches, mechanically driven clutches, etc., which can solve the problem of large elastic deformation, reducing the strength of the outer ring 114 on the control rod side and the outer ring 122 on the braking device side, and difficult to improve damage Torque and other issues, to achieve the effect of increasing strength, increasing breaking torque, and reducing elastic deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

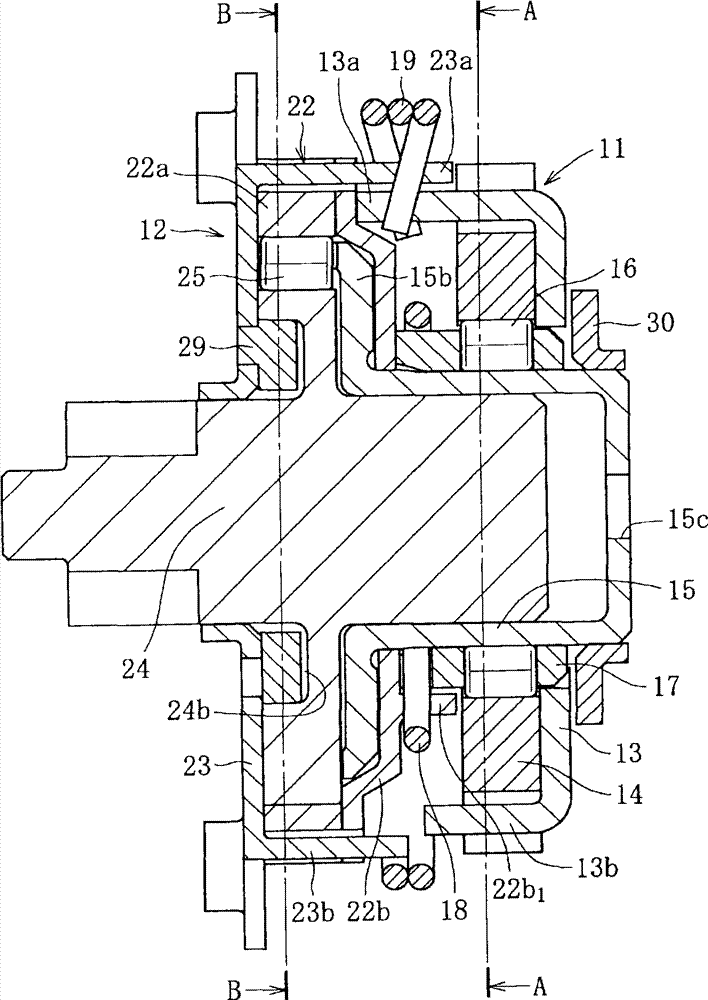

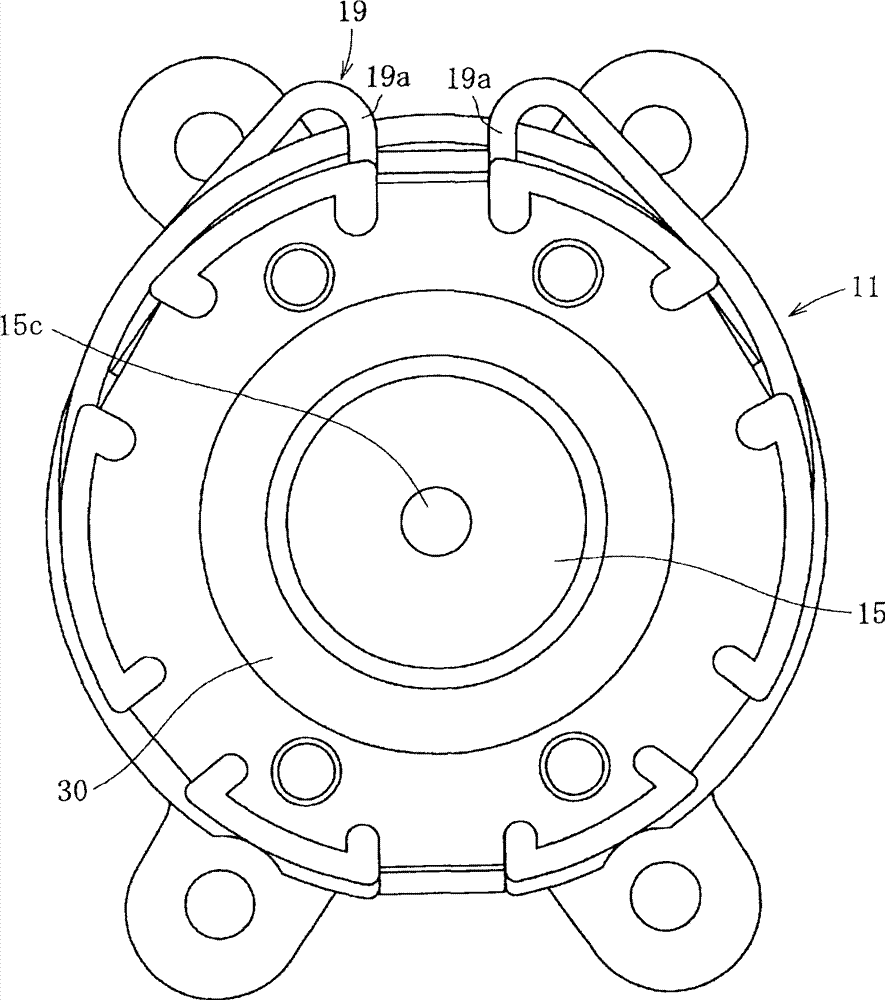

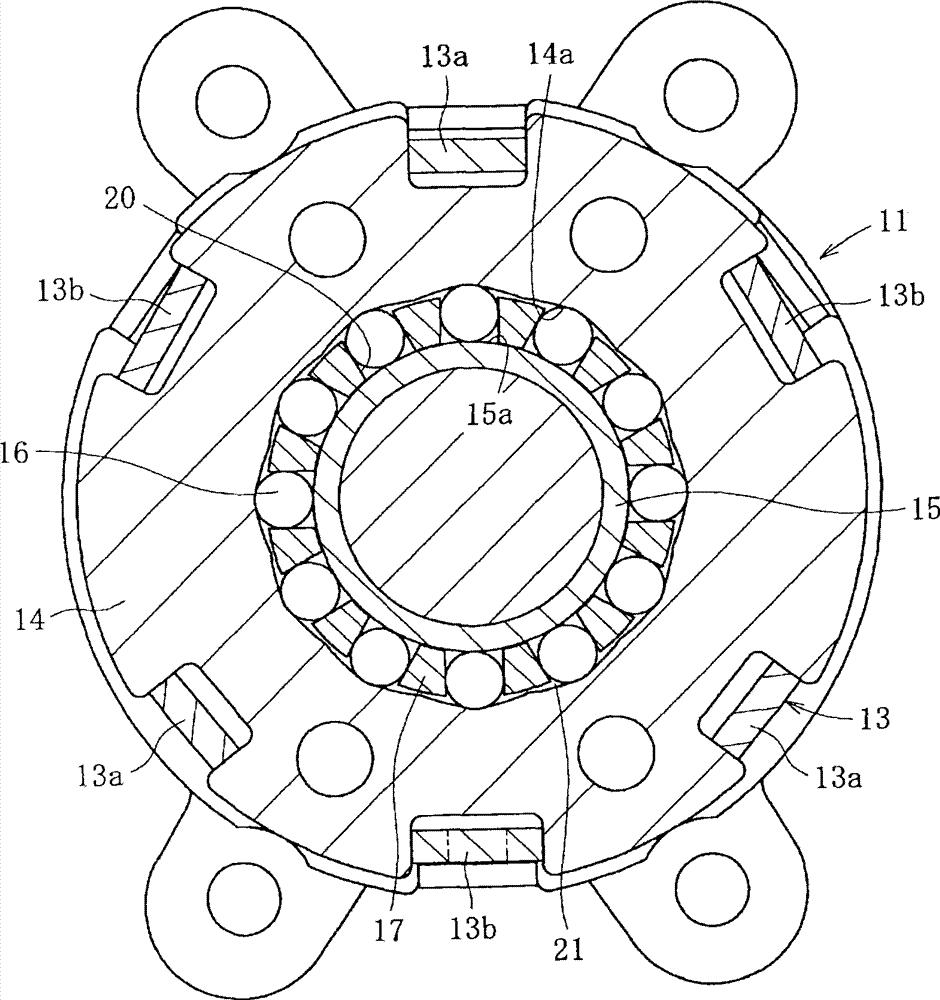

[0043] figure 1 It is a sectional view showing the overall structure of a clutch unit according to an embodiment of the present invention, figure 2 yes figure 1 right side view of the image 3 is along figure 1 The sectional view of the line A—A, Figure 4 is along figure 1 The sectional view of the B-B line.

[0044] This clutch unit includes: a lever side clutch part 11 provided on the input side; and a brake device side clutch part 12 provided on the output side with an opposite input blocking function.

[0045] The lever-side clutch unit 111 includes, for example, a lever-side outer ring 14 as an input-side member to which a lever (not shown) is connected; an inner ring 15 as a connecting member; and, for example, a plurality of cylindrical rollers as engagement members. 16. A retainer 17 for holding the cylindrical roller 16; an inner return spring 18 as a first elastic member for returning the retainer 17 to a neutral state; a function for returning the lever ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com