Garden shears security device

A technology of safety device and gardening shears, which is applied to the equipment of pruning shears, etc., can solve the problems of increased manufacturing cost, difficult assembly, and complexity, and achieve the effects of lower unit price, easy assembly, and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

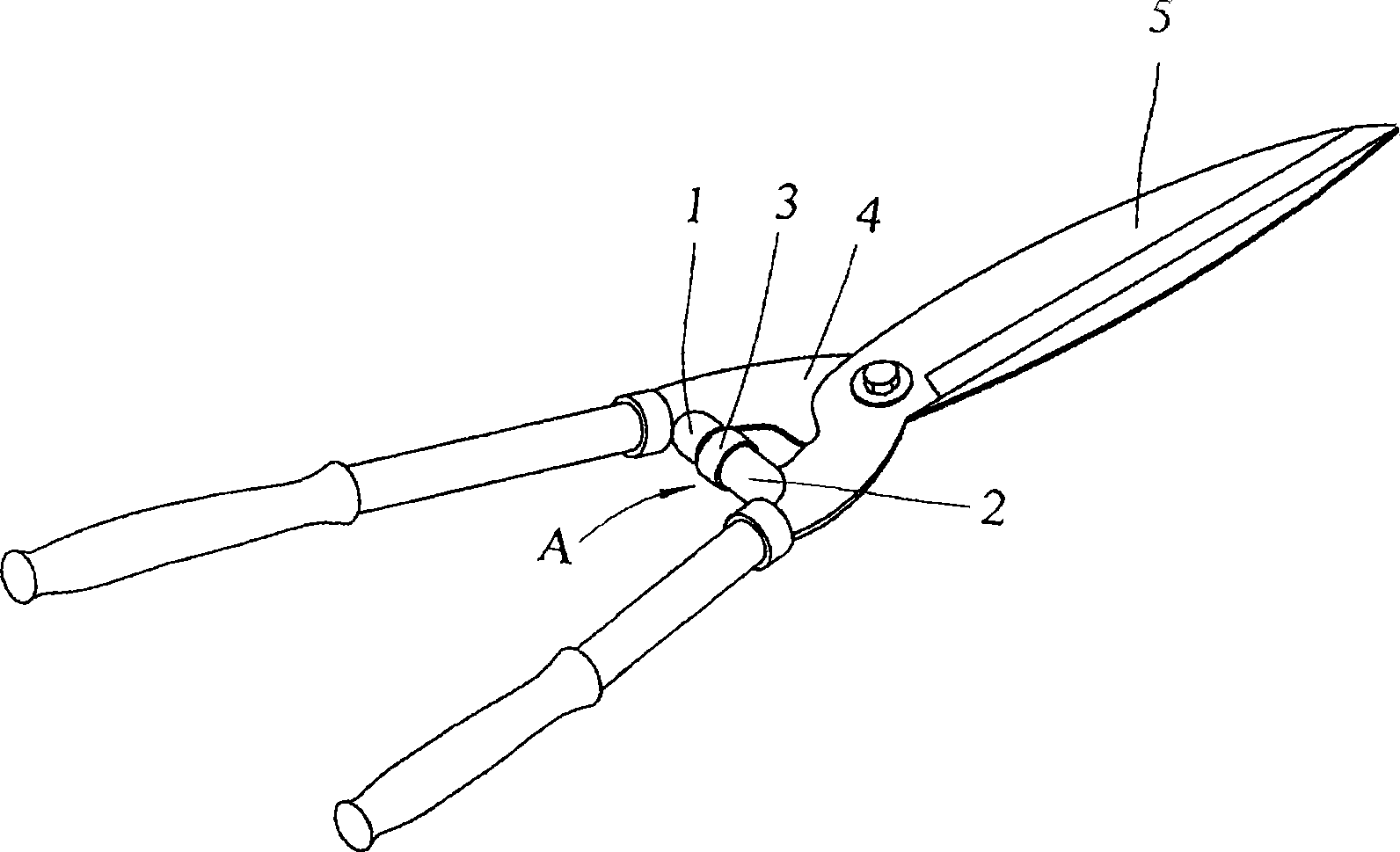

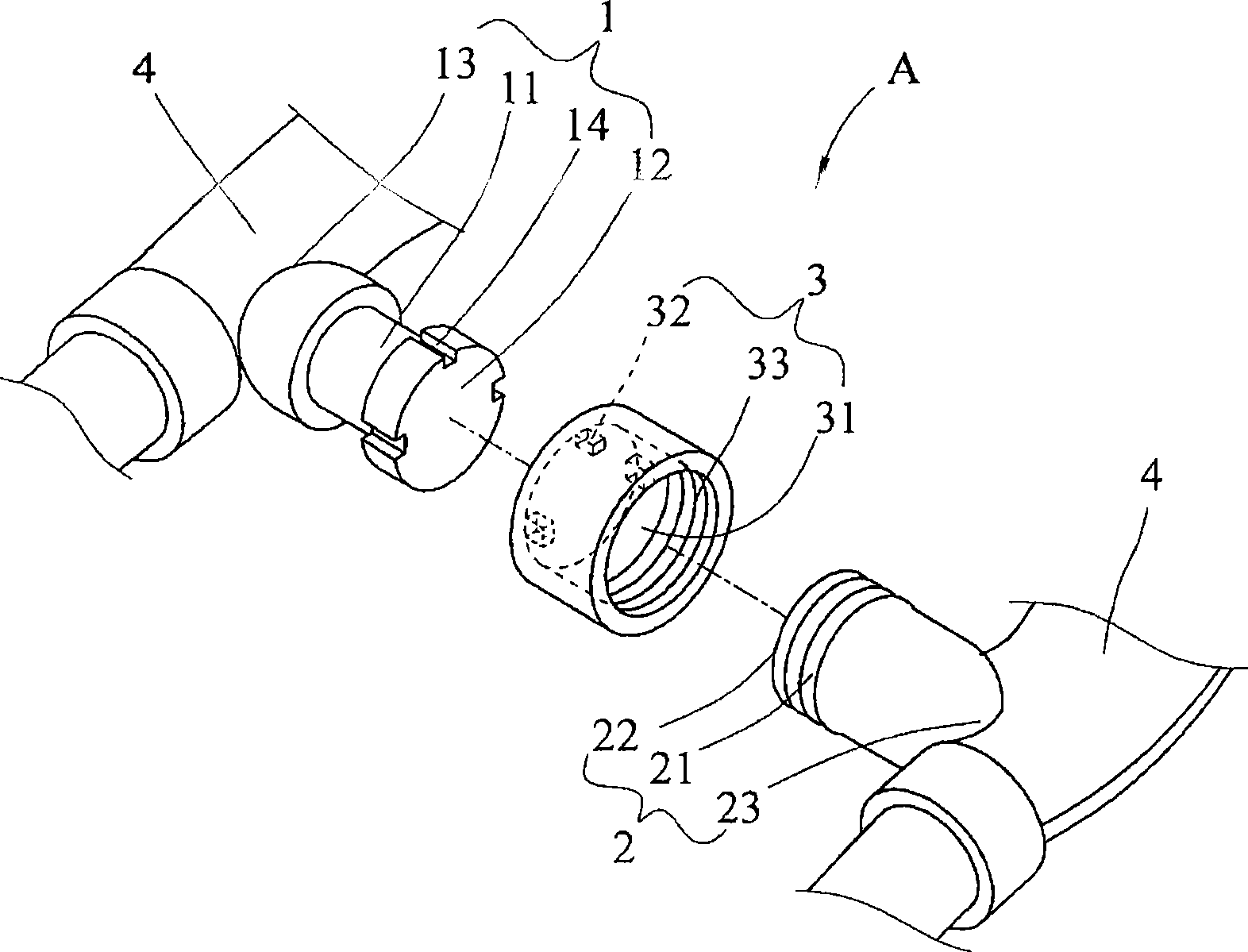

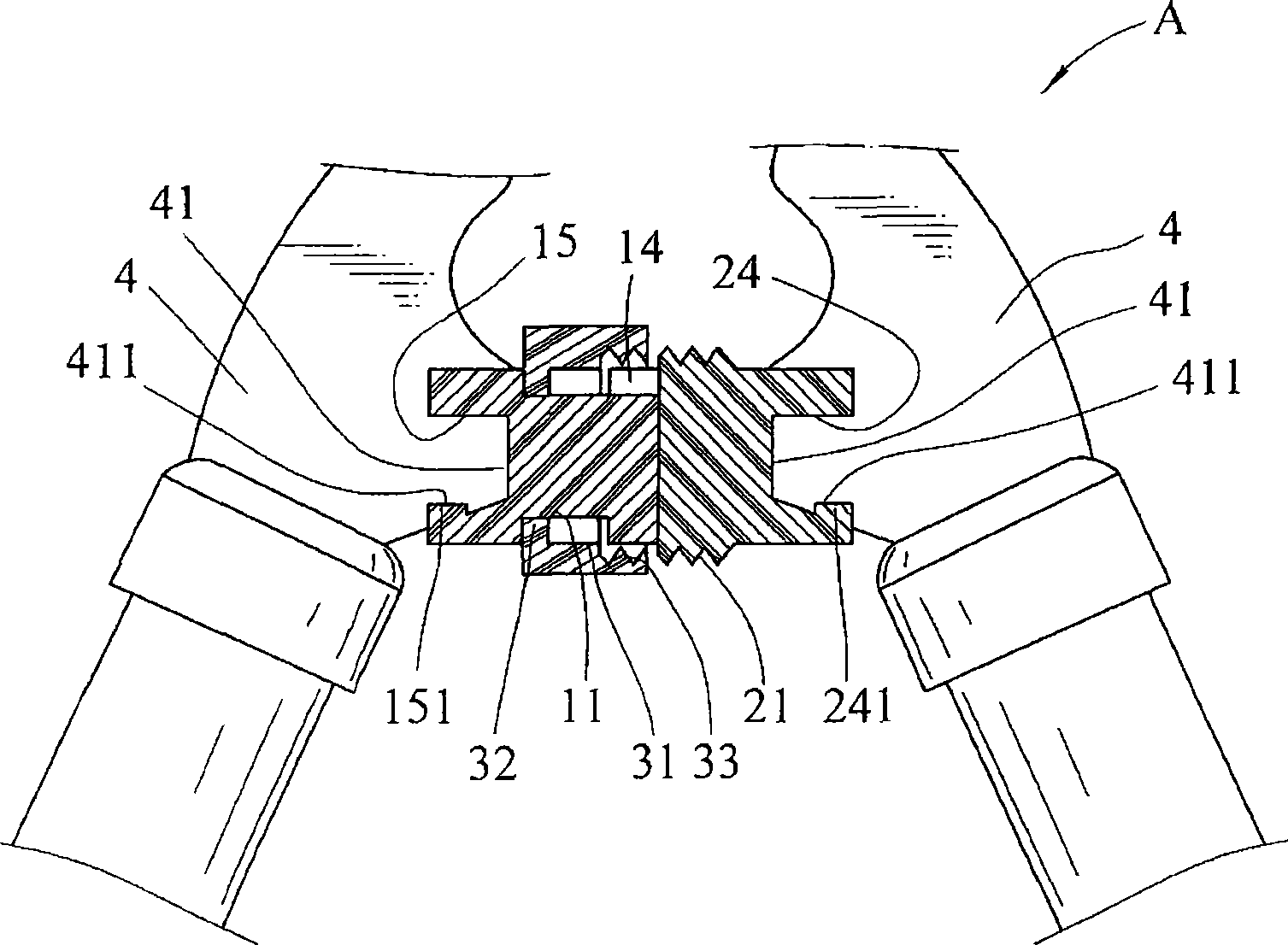

[0032] see figure 1 , 2 As shown, the present invention A is a safety device for gardening shears, which is assembled on the upper side of the handle 4, and includes: a first stop part 1, a second stop part 2, and a connecting piece 3; wherein, the The first stopper 1, which is basically a cylinder, is provided with a ring groove 11 at a predetermined place in the middle, and at one end 12, and an axial groove 14 is provided at one-third of its periphery. , the groove 14 is basically a square groove, and its other end 13 is provided with a jack 15 for combining with the handle 4 .

[0033] The second stop part 2 is also basically a cylinder, and one end 22 of the first stop part 1 is provided with a male thread 21, and the other end 23 is also provided with an insertion hole 24 for combining with the handle 4. the use of.

[0034] A connecting piece 3 is basically a cylindrical hollow body, and its outer diameter is slightly larger than the outer diameter of the first stop...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com