Construction column used for masonry structure and its production method and special precast segment

A technology of masonry structure and structural column, applied in the field of structural column, can solve the problems of high labor cost of construction personnel, non-standard binding of steel cage, low construction level, etc., and achieves saving concrete material cost, low construction technical requirements, and saving construction. The effect of the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

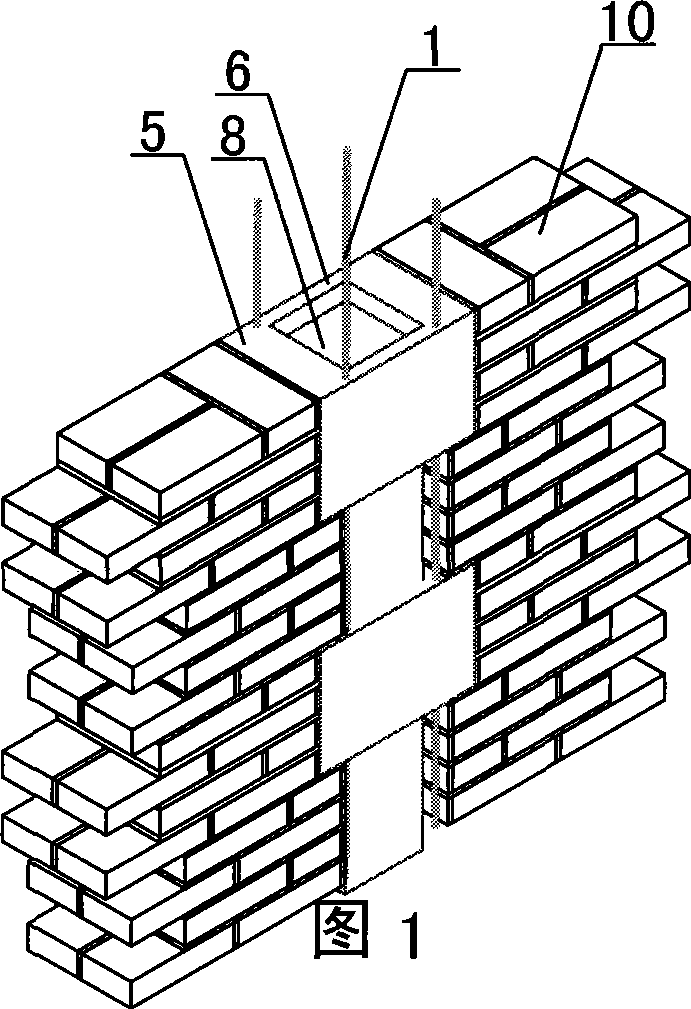

[0068] As shown in Figure 1, a structural column for a masonry structure is characterized in that it is mainly assembled from prefabricated sections 2 with four longitudinal reinforcements 1; the vertical reinforcements 1 of adjacent prefabricated sections 2 It is a binding connection; there is a horse-tooth bar 5 engaged with the wall 10 on the construction column; the above-mentioned longitudinal reinforcement 1 is interspersed in the four corners of the regular square prism 6 in the above-mentioned prefabricated section 2 along the vertical axis; the structure of this embodiment The column is suitable for the middle part of the in-line wall; the prefabricated section used has two curbs on the same line.

Embodiment 2

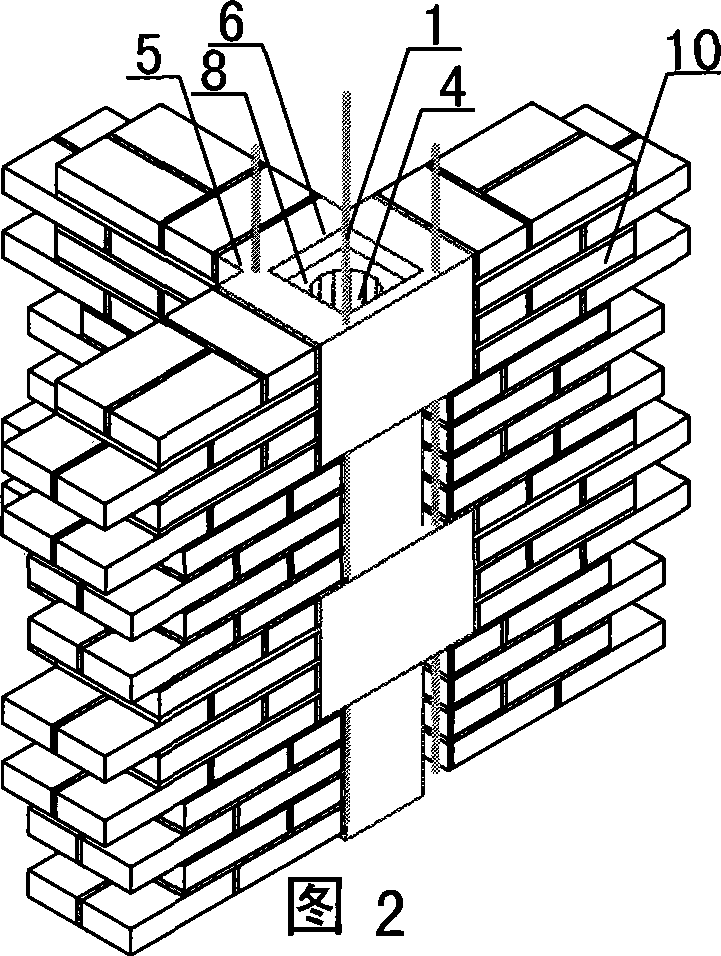

[0070] As shown in Figure 2, a structural column for masonry structures is characterized in that it is mainly composed of prefabricated sections 2 with four longitudinal reinforcements 1 and cavities 3; the upper and lower adjacent prefabricated sections 2 The longitudinal rib 1 is welded; the cavities 3 of the upper and lower prefabricated sections 2 overlap to form the cavity 4 of the structural column, and the cross section of the cavity 4 is circular; the structural column has a buttress 5 engaged with the wall 10; The above-mentioned longitudinal ribs 1 are interspersed in the four corners of the regular square prism 6 in the above-mentioned prefabricated section 2 along the vertical axis; the construction column of this embodiment is suitable for a T-shaped wall; the prefabricated section used has three horse teeth. Of course, concrete can also be poured into the cavity of the construction column in this embodiment as required.

Embodiment 3

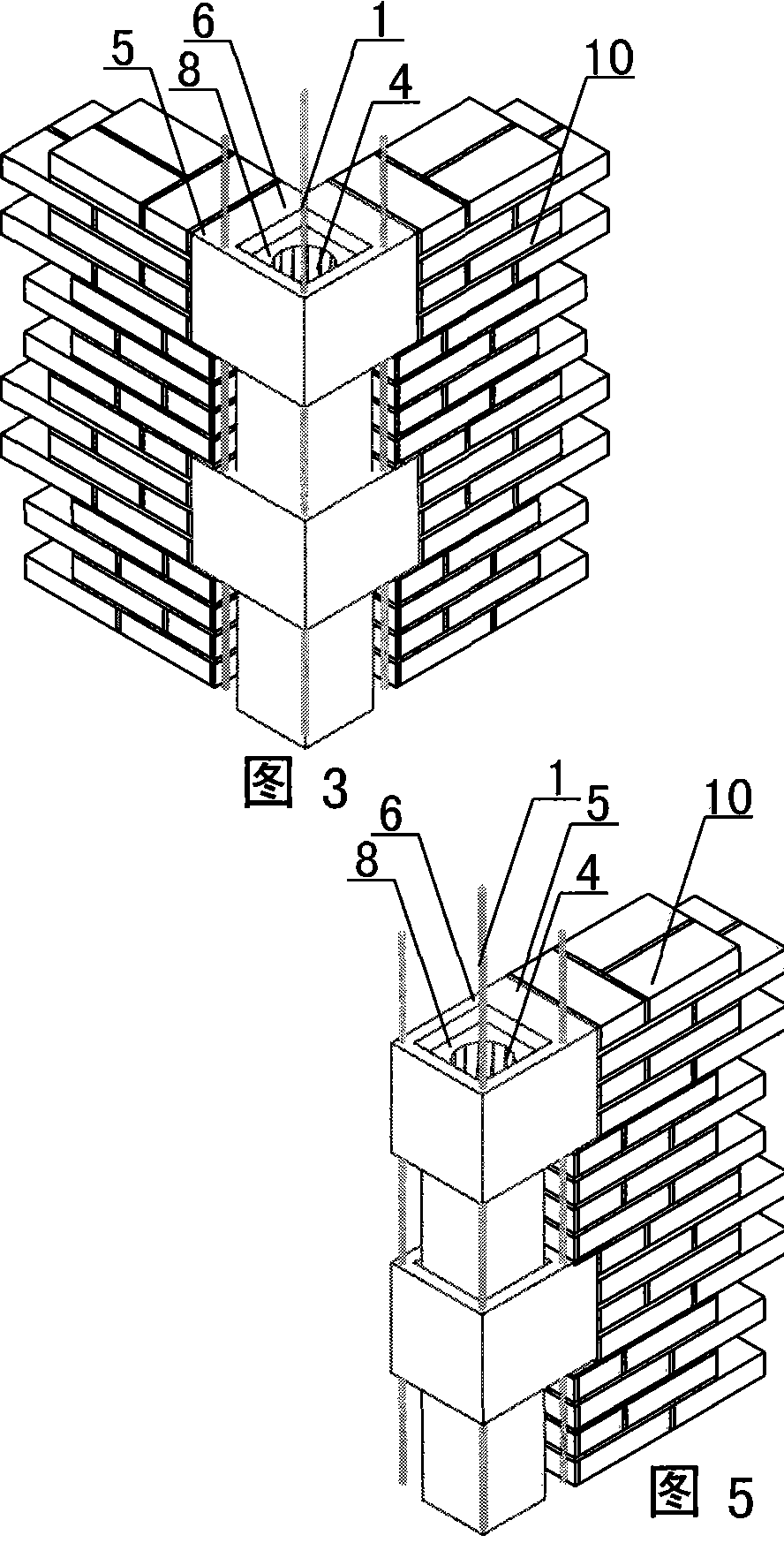

[0072] As shown in Figure 3, a structural column for masonry structures is characterized in that it is mainly composed of prefabricated sections 2 with four longitudinal reinforcements 1 and cavities 3; the upper and lower adjacent prefabricated sections 2 The longitudinal reinforcement 1 is bound and connected; the cavities 3 of the upper and lower prefabricated sections 2 overlap to form the cavity 4 of the structural column, and the cross section of the cavity 4 is circular; ; The above-mentioned longitudinal reinforcement 1 is interspersed in the four corners of the regular square prism 6 in the above-mentioned prefabricated section 2 along the vertical axis; the construction column of this embodiment is suitable for L-shaped walls; the used prefabricated section has two mutually perpendicular Ma Yacha. Of course, concrete can also be poured into the cavity of the construction column in this embodiment as required.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com