Steel plate spring stiffness and arc height measuring system and measurement compensation method

A leaf spring, measuring system technology, applied in measuring devices, elastic testing, mechanical measuring devices, etc., can solve the problems that the sensor cannot eliminate gravity and gap, the sensor sensitivity is not high, the pressure sensor has a large range, etc., and achieves high reliability. , the drawing is simple and accurate, and the effect of improving the measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

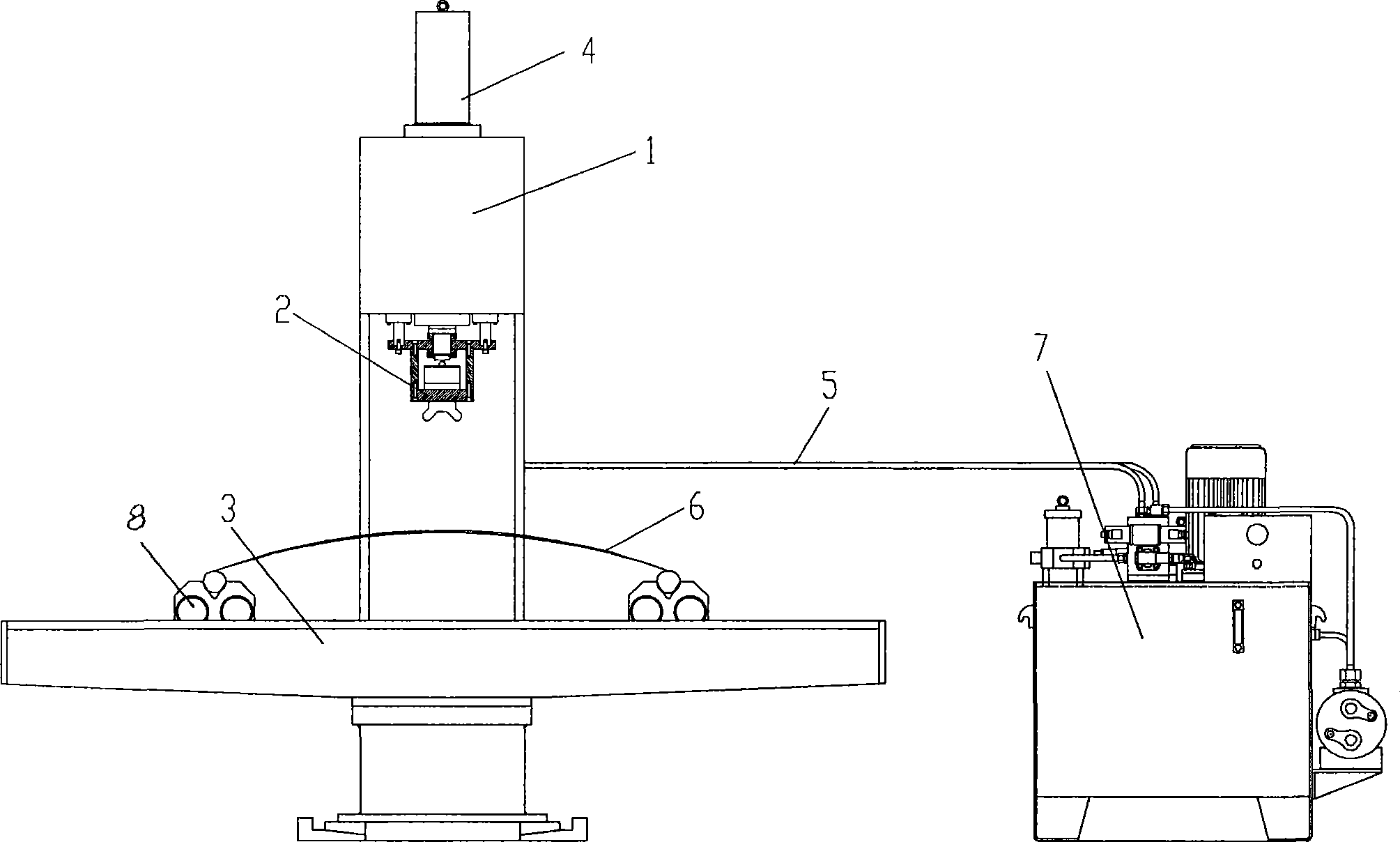

[0032] see figure 2 , the measurement system in this embodiment includes

[0033] A horizontal reference platform 3, the leaf spring 6 to be tested is supported on the reference platform 3 by the pulleys 8 at both ends;

[0034] One is located above the leaf spring 6 under test, at the center of the leaf spring 6 under test, and is vertically arranged as a pressure rod 12 that can move up and down. The bottom end of the pressure rod 12 passes through the action block 14 on the pressure head 2 Can apply pressure to the leaf spring under test;

[0035] A pressure sensor 13 is used to measure the pressure applied by the pressure rod 12 to the leaf spring 6 to be tested through the action block 14;

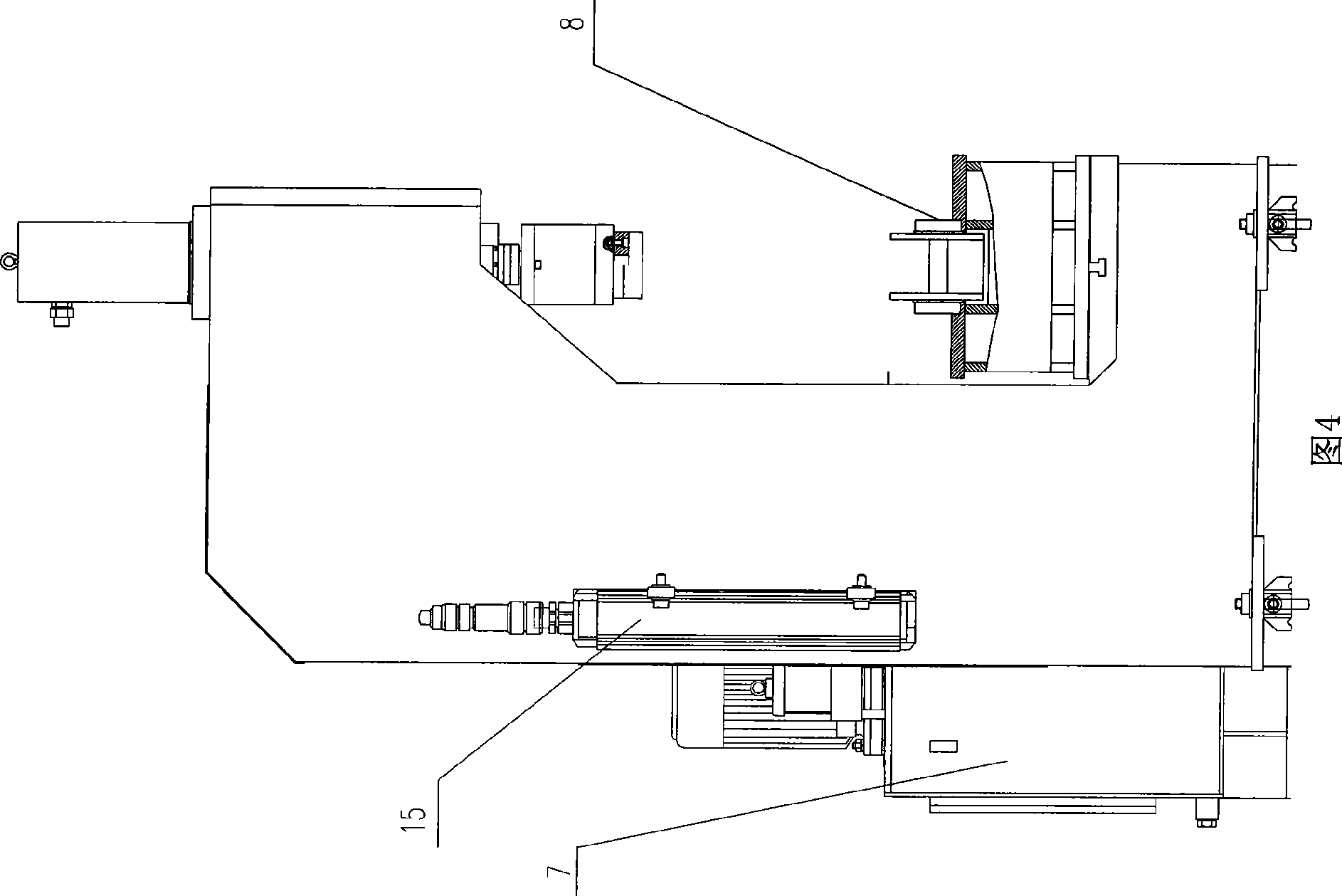

[0036] A displacement sensor 15 is used to measure the displacement of the action block 14 relative to the zero point O1.

[0037] In specific implementation, such as figure 2 , Fig. 3, shown in Fig. 4, frame 1 is set above reference platform 3, hydraulic cylinder 4 is fixedly set...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com