Feed pump and sealing arrangement for same

A technology for conveying pumps and seals, which is applied to pumps, pump components, variable capacity pump components, etc., can solve the problems of long-term shutdown and the known sealing structure has a low service life, and achieves easy polymerization and improved service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

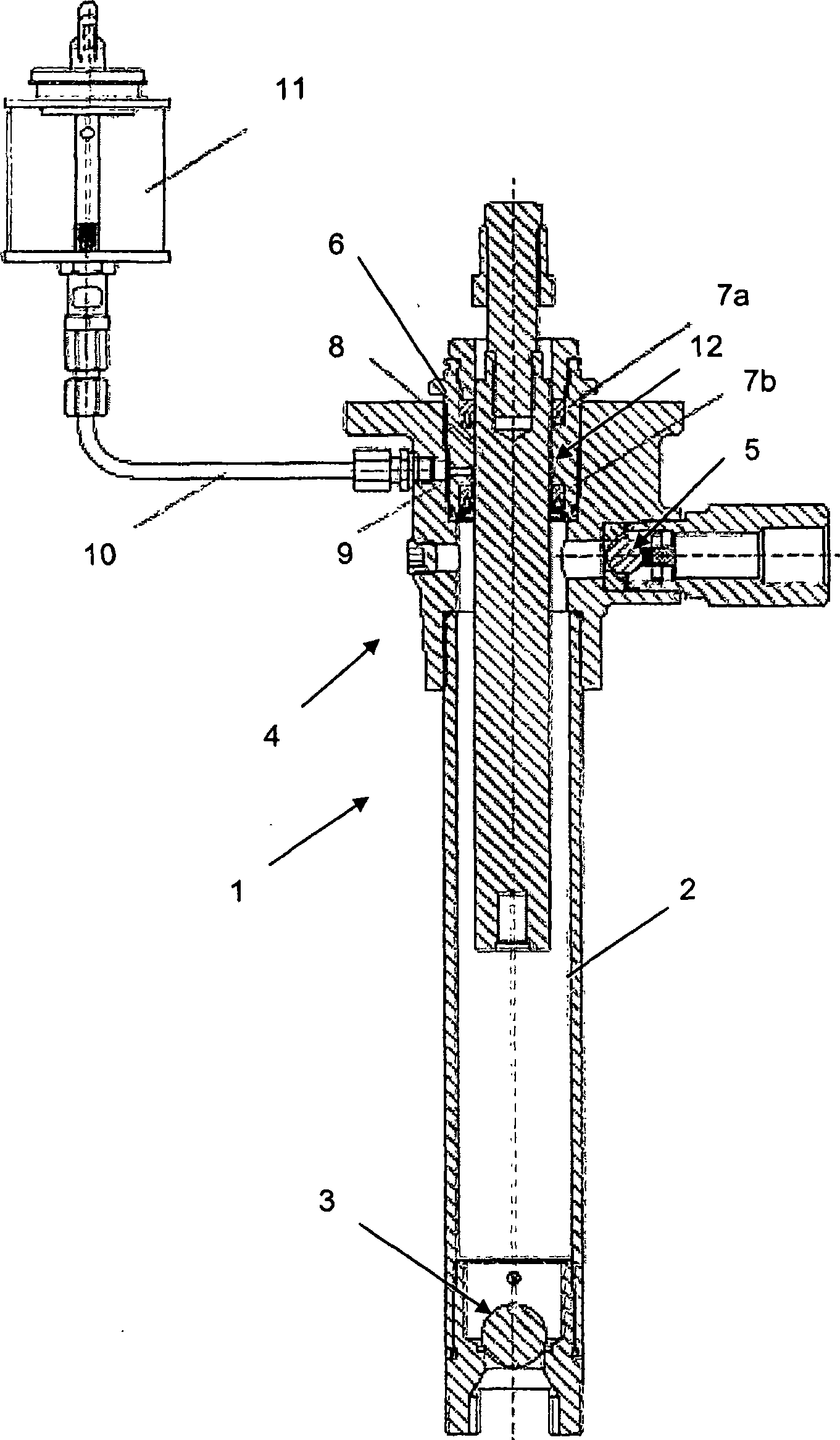

[0016] The single FIGURE shows the structure of the delivery pump 1 in a schematic sectional view. The delivery pump comprises a pump housing 2 designed essentially as a cylindrical tube, the lower side of which in the figure is closed by an inlet valve 3 designed as a non-return valve. The inlet valve 3 is constructed and arranged to allow inflow into the pump housing 2 and prevent outflow from the pump housing 2 .

[0017] On the upper side in the figure, the pump housing 2 is hermetically closed by a connection 4 from which an outlet valve 5 likewise designed as a non-return valve branches off, which is constructed and arranged so as to allow Fluid flows out of the pump casing 2 while inflow into the pump casing 2 is blocked.

[0018] In addition, a threaded section is provided on the connection 4 , into which a screw-in sleeve 6 is screwed in in a leak-tight manner. Arranged in the screw-in sleeve 6 are two spaced apart seals 7 a , 7 b designed as groove seals. A piston...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com