Fresh-keeping method of tea fresh leave

A fresh-keeping method and fresh leaf technology, applied in the direction of tea processing before extraction, can solve the problems of affecting the quality of green tea, not being able to process it in time, and the processing equipment being idle and wasteful, so as to solve the difficulty in controlling the throughput of raw materials, improve the quality and prolong the The effect of the machining cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

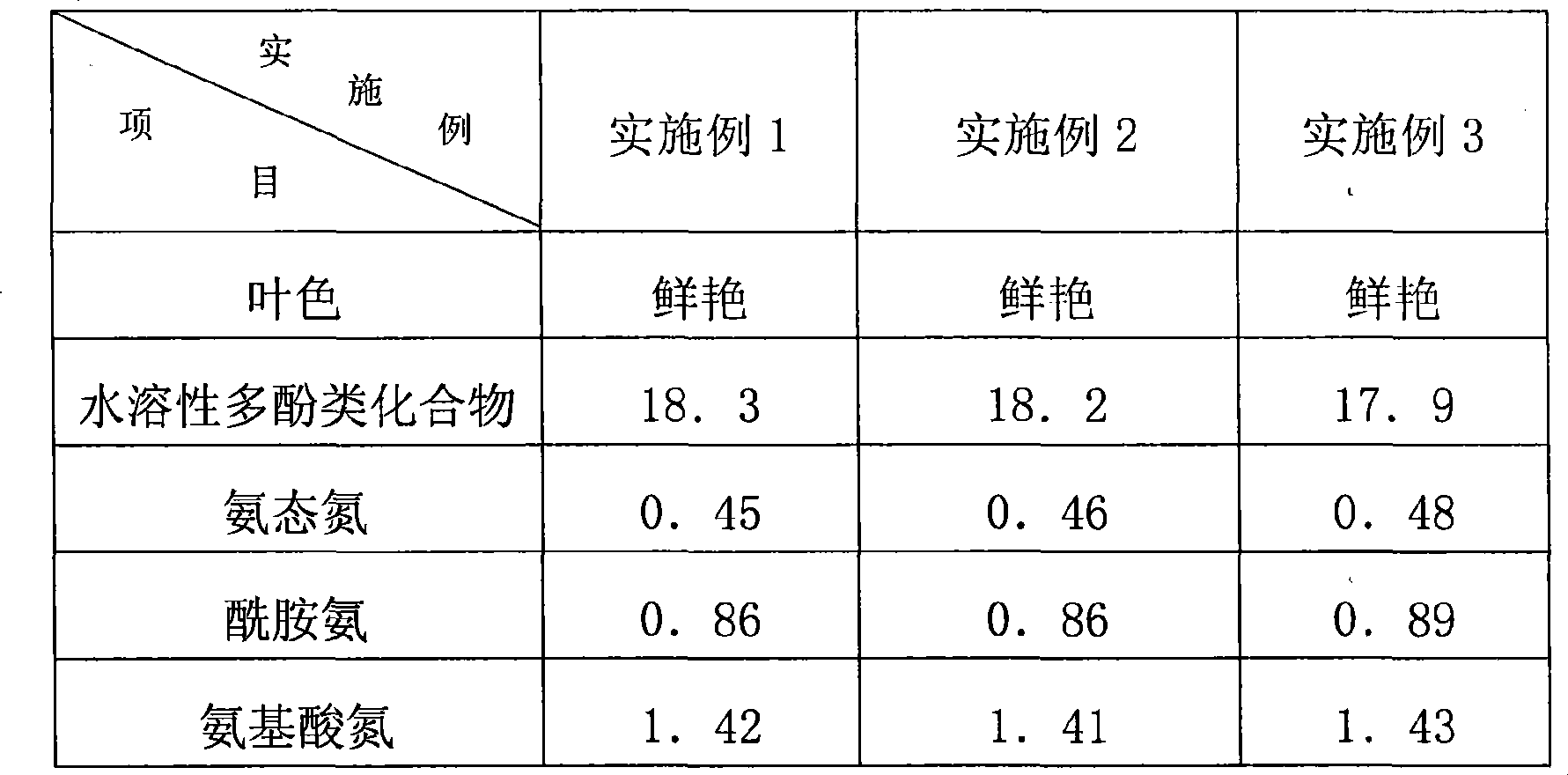

Embodiment 1

[0013] 1. Fresh leaf grading process: Send the fresh leaves picked on sunny days before Qingming to the 6CFJ-70 tea fresh leaf grading machine for grading. According to the difference of buds and leaves, the fresh leaves are divided into 3 grades. First exhibition, one bud and one), second grade (one bud and two leaves first exhibition, one bud and two leaves), third grade (one bud and three leaves first exhibition, one bud and three leaves);

[0014] 2. Packing process of fresh leaves: put first-grade fresh leaves into small (68cm×48cm×30cm) leaf storage boxes, second-grade fresh leaves into medium-sized (68cm×48cm×35cm) leaf storage boxes, third-grade fresh leaves into a large (68cm×48cm×40cm) leaf storage box;

[0015] 3. Fresh storage storage process:

[0016] The temperature of the first-grade fresh leaves is 0°C, the temperature of the second-grade fresh leaves is 2°C, and the temperature of the third-grade fresh leaves is 4°C;

[0017] The first-grade fresh leaf humid...

Embodiment 2

[0020] The fresh-keeping process is as follows: the temperature of the first-grade fresh leaves is 2°C, the temperature of the second-grade fresh leaves is 5°C, and the temperature of the third-grade fresh leaves is 6°C;

[0021] The first-grade fresh leaf humidity is 82%, the second-grade fresh leaf humidity is 87%, and the third-grade fresh leaf humidity is 92%; outside, all the other are identical with embodiment 1.

[0022] The preservation time is 5 days.

Embodiment 3

[0024] The fresh-keeping process is as follows: the temperature of the first-grade fresh leaves is 5°C, the temperature of the second-grade fresh leaves is 7°C, and the temperature of the third-grade fresh leaves is 8°C;

[0025] The first-grade fresh leaf humidity is 85%, the second-grade fresh leaf humidity is 90%, and the third-grade fresh leaf humidity is 95%; outside, all the other are identical with embodiment 1.

[0026] The shelf life is 7 days.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com