Turbine blade CT detection device and detection method

A turbine blade and detection device technology, which is applied in the direction of using radiation for material analysis, etc., can solve problems such as easy missed detection and inability to adjust the angle of the ray fan.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

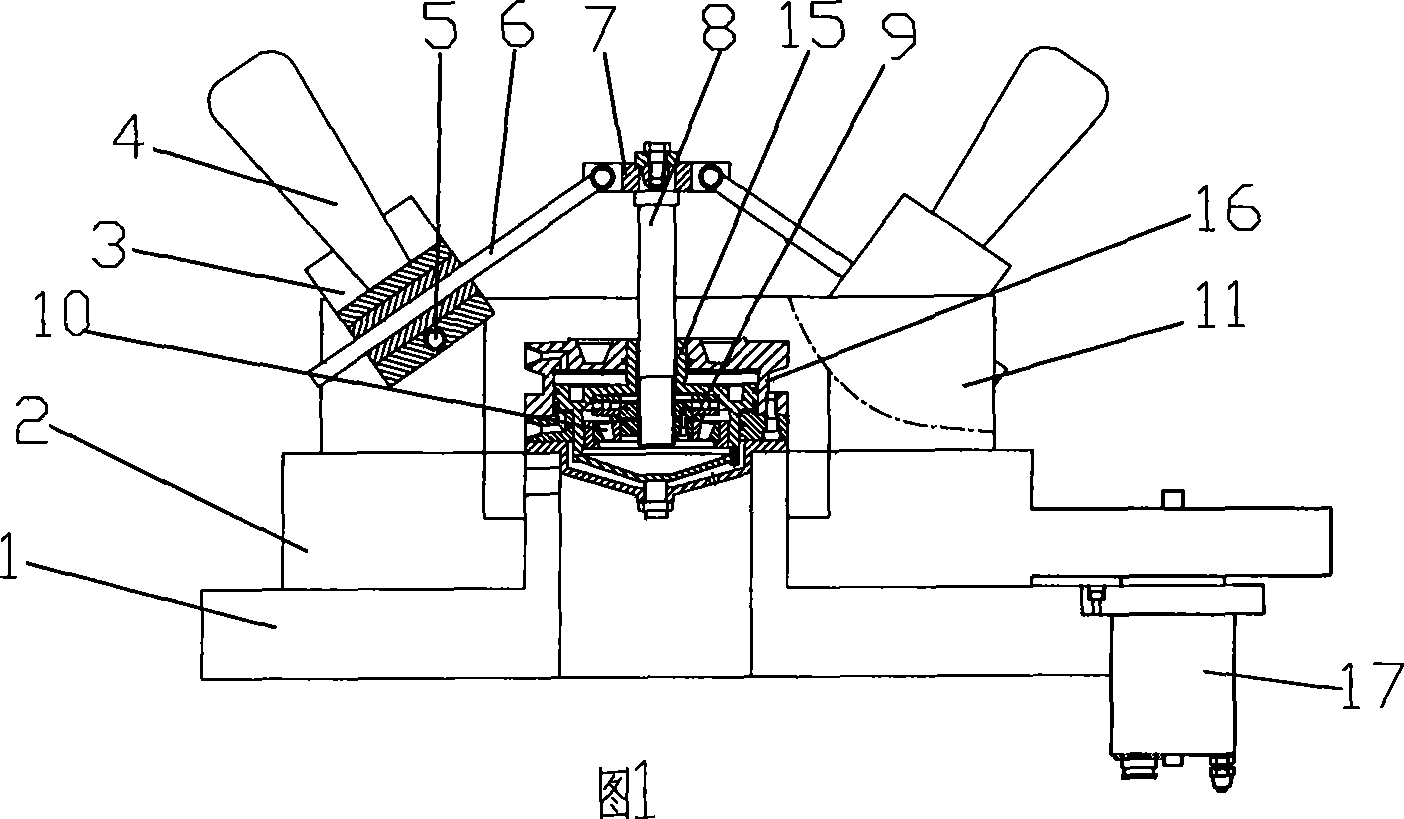

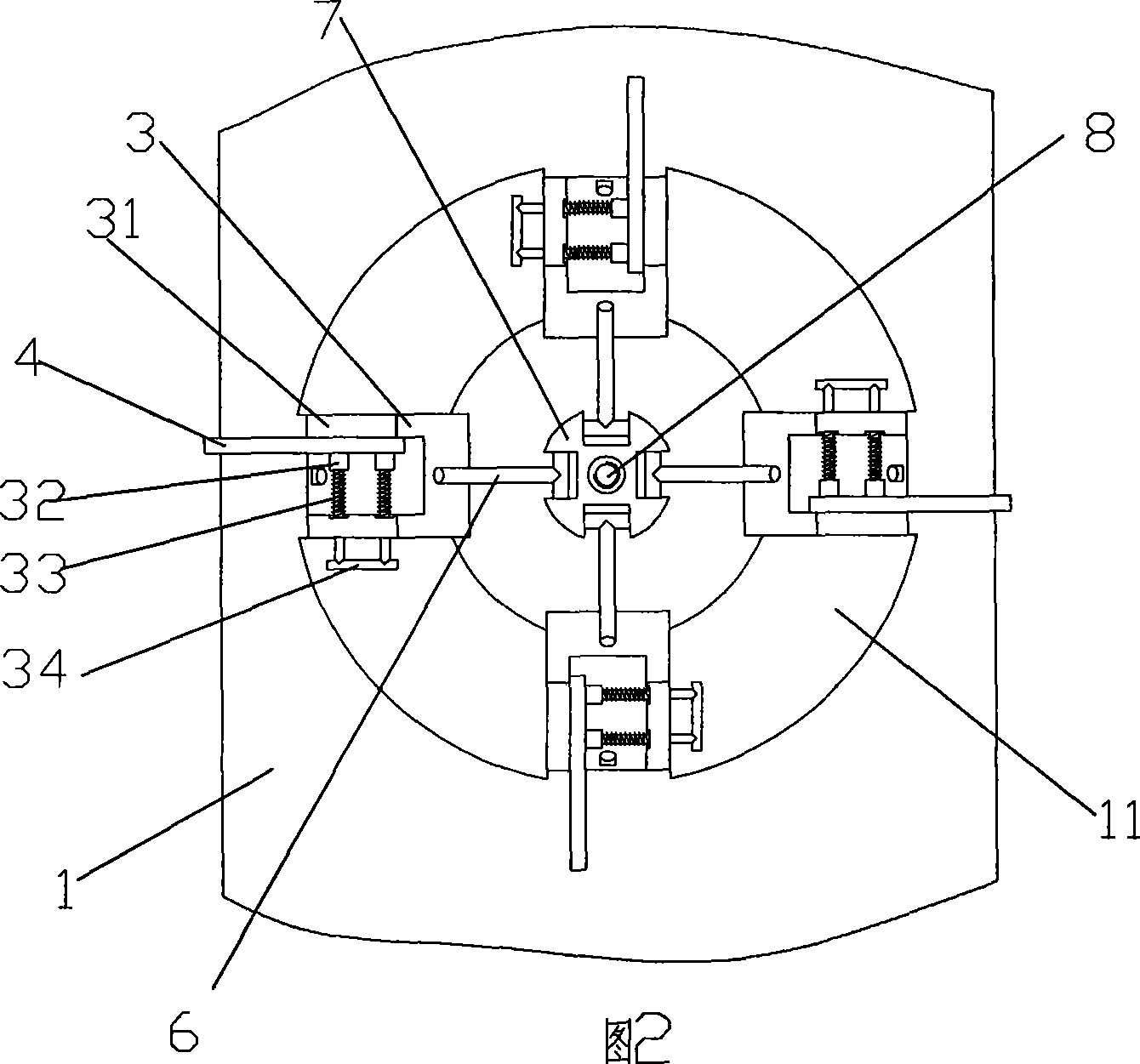

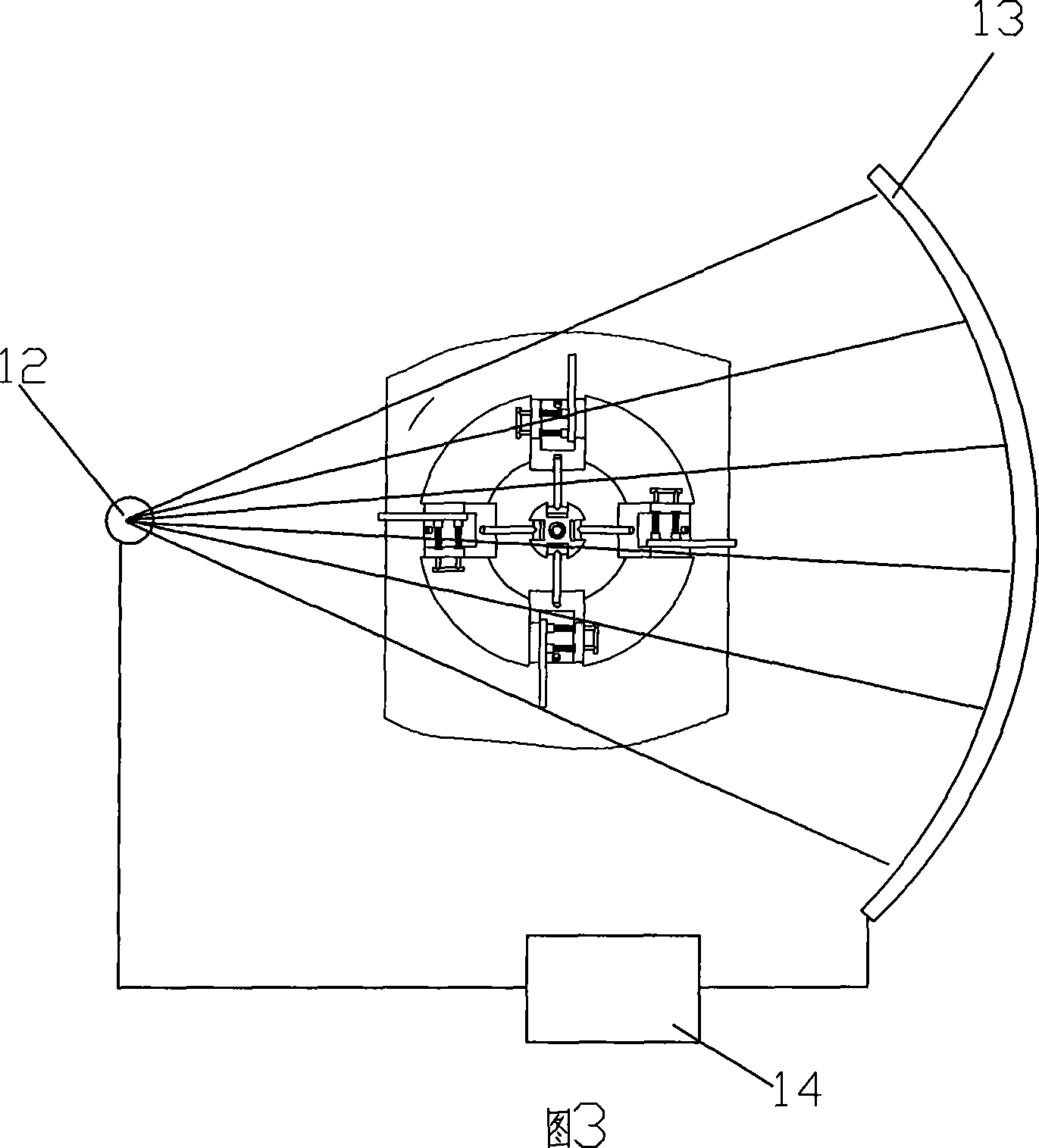

[0051] Fig. 1 is a schematic cross-sectional view of the structure of the present invention, Fig. 2 is a top view of Fig. 1, and Fig. 3 is a schematic diagram of the present invention, as shown in the figure: the turbine blade CT detection device of the present embodiment includes a workbench 1, a ray generating device 12, Data acquisition device 13 and control and image processing system 14, in the present embodiment, data acquisition device 13 is arc-shaped linear array detector, and described workbench 1 is positioned at the inner side of arc-shaped linear array detector, adopts linear array detector , can avoid the crosstalk of rays; the ray generating device 12 and the data acquisition device 13 are connected with the control and image processing system 14;

[0052] It also includes a retractable rotary fixture, which includes a rotary table 2, a rotary table drive device 17, a pull rod 8, a pull rod drive device, and at least one swing rod 6 and a clamping body 3 distribu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com