Numerical control machining tool heat error Bayes network compensation method

A Bayesian network and compensation method technology, applied in the field of Bayesian network compensation for thermal error of CNC machine tools, can solve problems such as operating condition uncertainty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further explained below in conjunction with the drawings and the implementation process.

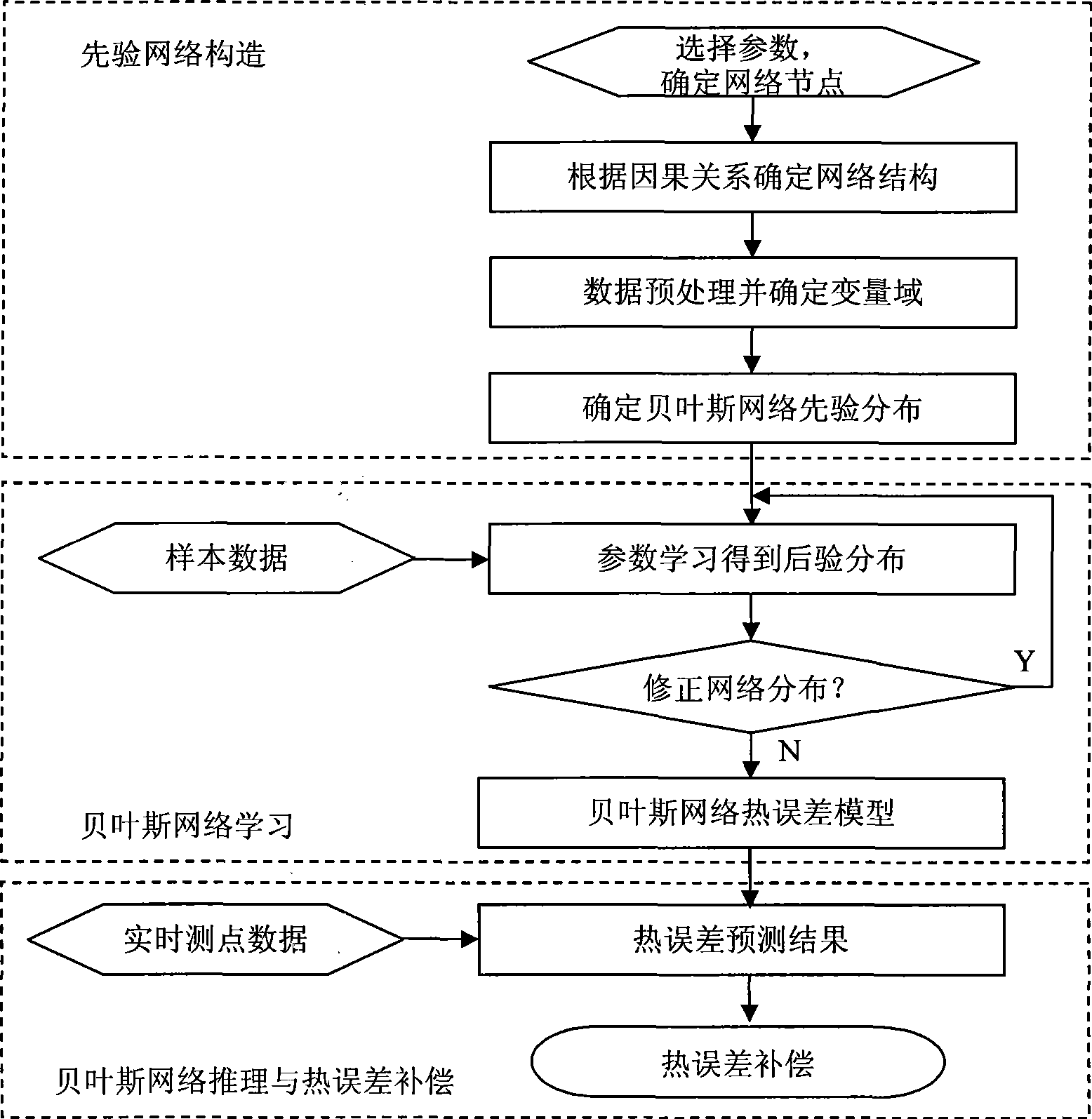

[0037] The thermal error modeling method of the present invention is a reasoning method based on the principle of probability and combined with graph theory. It is implemented in the following steps (such as figure 1 Shown):

[0038] 1) Construct a priori Bayesian network.

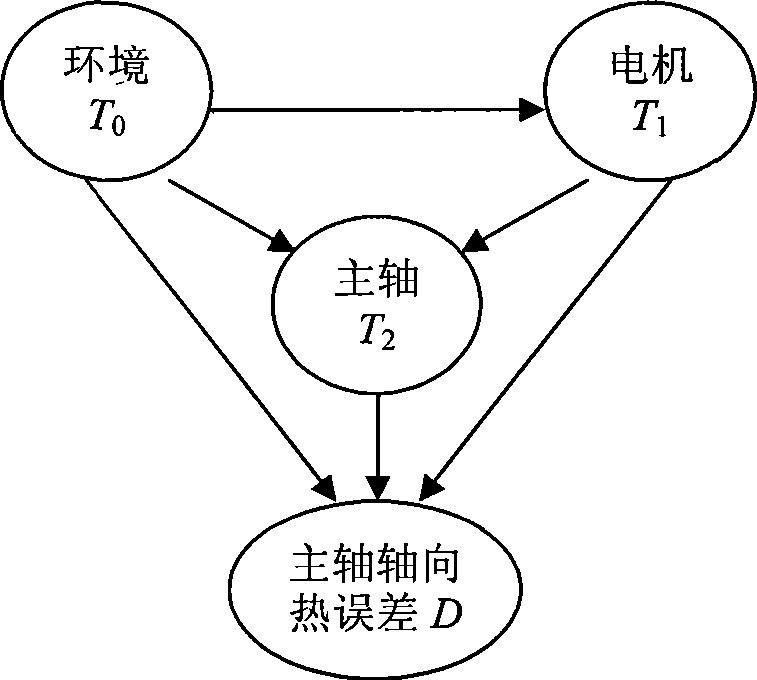

[0039] The thermal error of the machine tool depends on the temperature change and is related to many factors such as the processing cycle, the use of coolant, and the surrounding environment. Take these factors together with the thermal error as a set of variables in the model. Use a directed acyclic graph to describe the relationship between variables. The nodes in the graph represent random variables, and the edges between nodes represent the direct dependencies between variables. Each node X i With probability distribution P(X i |π(X i )), the root node X is attached to its edge ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com