Hearth carriage connection structure of rotary hearth furnace

一种回转炉床炉、炉床台车的技术,应用在炉、炉子类型、炉子组件等方向,能够解决炉床不能保持圆形、回转障碍等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

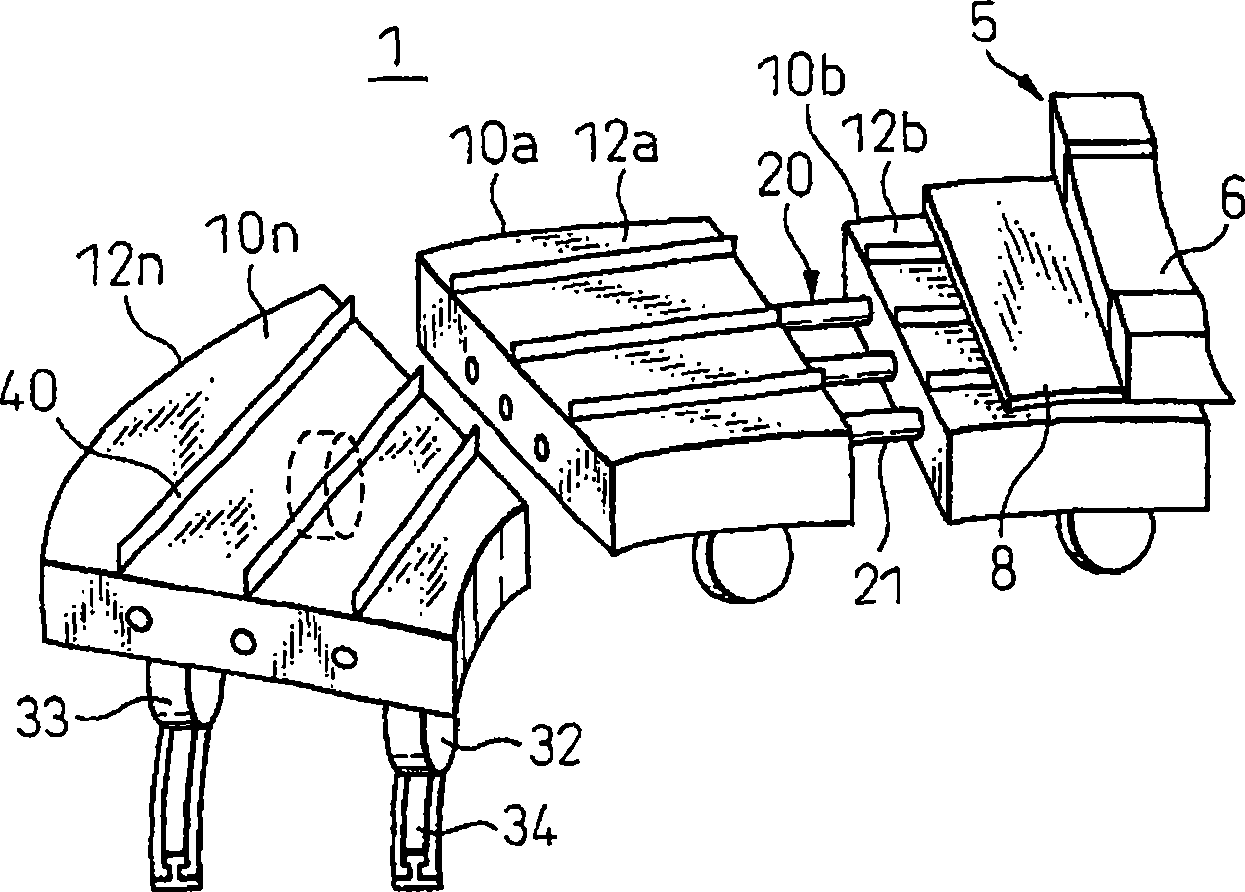

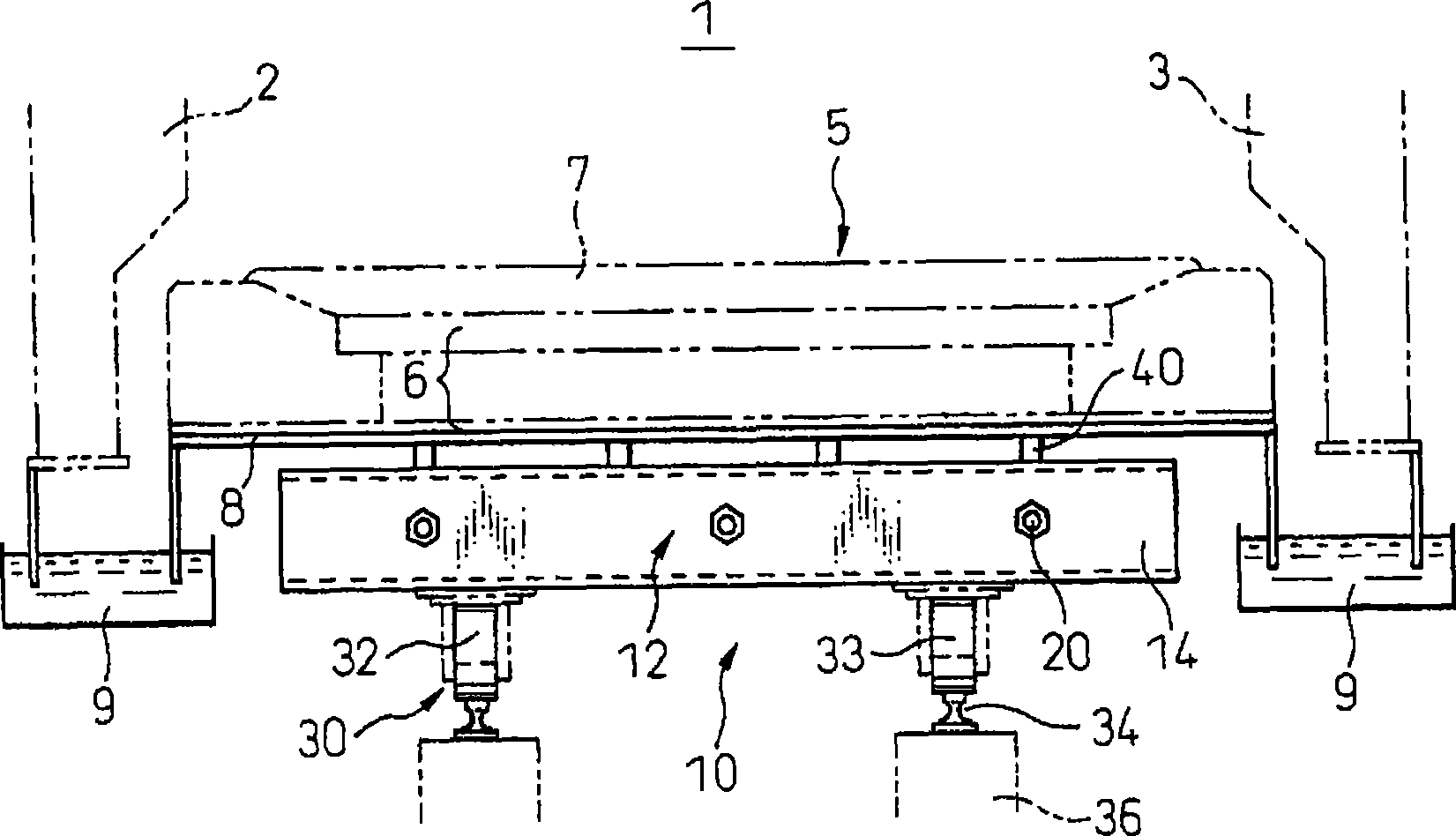

[0033] Figure 1~4 One embodiment of the present invention is shown. In this embodiment, the hearth 5 of the rotary hearth furnace 1 is constituted by connecting a plurality of hearth carriages 10 a to 10 n in a ring shape by a coupling device 20 . The hearth 5 is constructed of a refractory building bed 6 and a hearth material 7 . The refractory material building bed 6 is configured on the iron plate 8 above the trolley. The hearth trolley 10 mainly includes a trolley frame 12, a running device 30 and a metal piece 40 supporting an iron plate on the trolley.

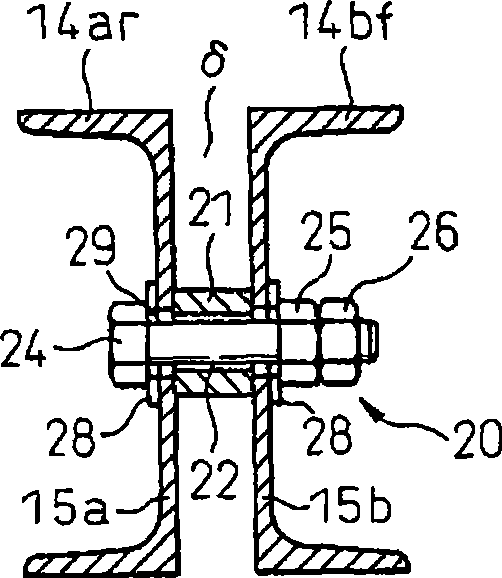

[0034] between hearth trolleys 10, as figure 1 As shown, a plurality of coupling devices 20 are arranged, and adjacent hearth carts 10 are coupled to each other by the coupling devices. A plurality of coupling devices 20 arranged between the trolleys are only arranged in one row on the same horizontal plane, and there is no such Figure 11 As shown in the example, it is arranged in two columns up and down. exist ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com