Plane scroll spring

A flat scroll spring and outer hook technology, applied in the direction of spring/shock absorber, coil spring, mechanical equipment, etc., can solve the problems of inconvenience, worker injury, affecting production efficiency, etc., and achieve the effect of convenient maintenance and replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The invention is a plane scroll spring.

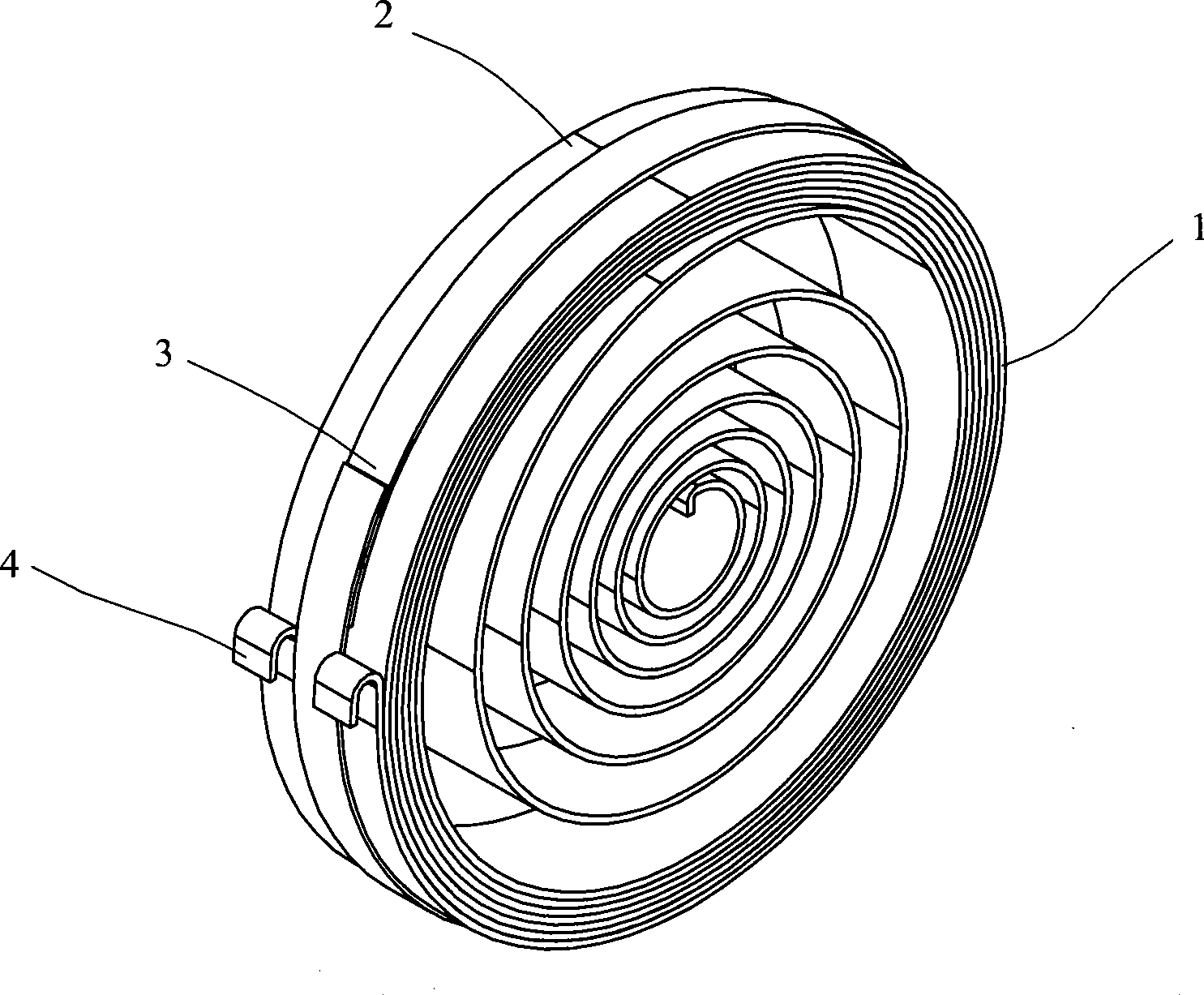

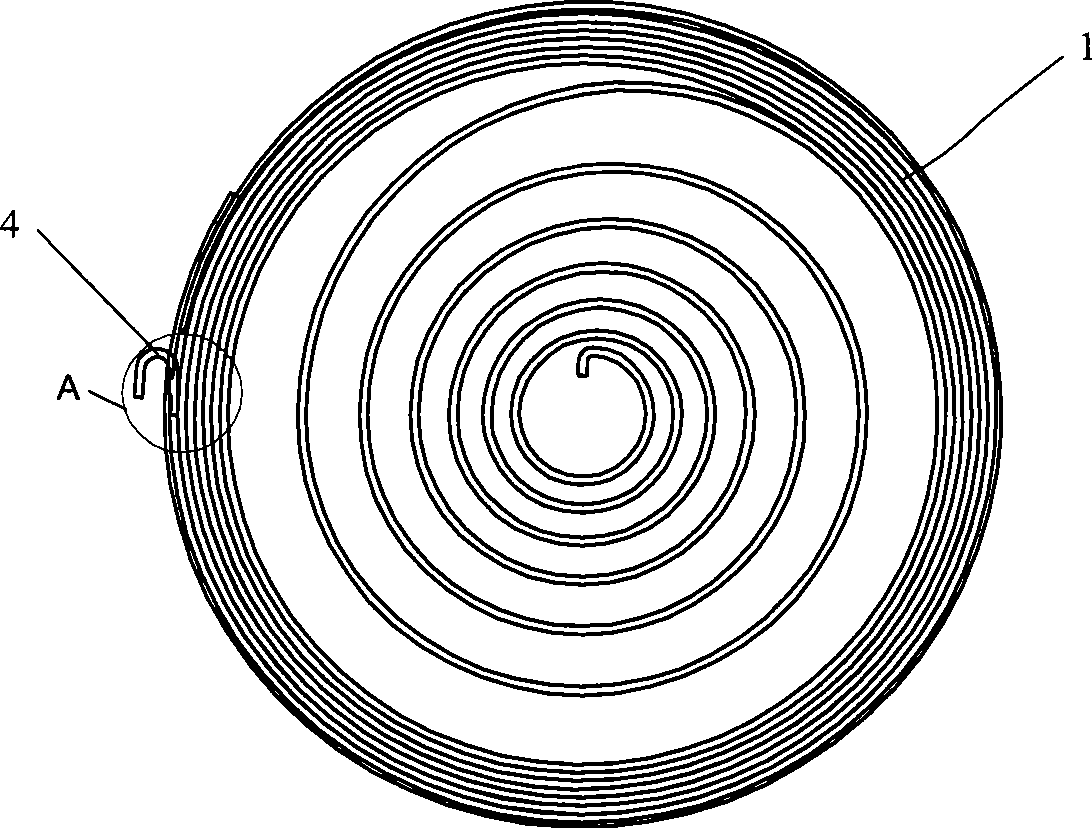

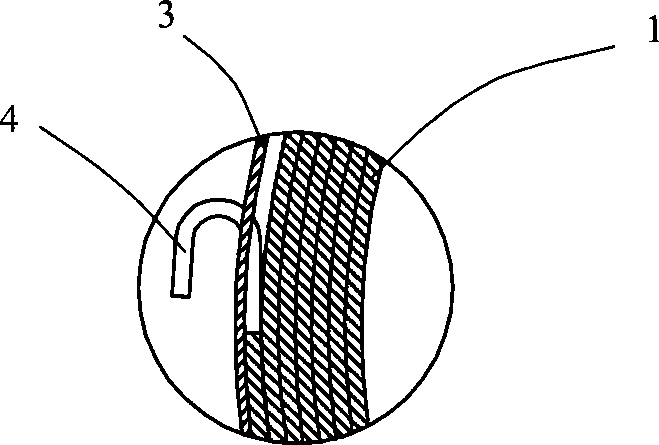

[0022] Figure 1 to Figure 3 Shown is an embodiment of the planar scroll spring, which includes a spring body 1 . A fixed ring 3 is provided outside the outermost ring 2 of the spring body 1 to limit the spring body 1 from bouncing off. The fixed ring 3 can be a steel band ring as shown in the figure, or a wire ring (not shown in the figure). The end of the outermost ring 2 has an outer hook 4 exposed outside the fixed ring 3 . The outer hook 4 can be spliced at the end of the spring body 1 or integrally formed with the end of the spring body 1 . Preferably, the width of the fixing ring 3 is smaller than the width of the spring body 1 .

[0023] In this embodiment, the fixed ring 3 is located at the middle position of the outermost ring 2 along the axial direction, and the outer hook 4 is divided into two parts, which are respectively located on both sides of the fixed ring 3 along the axial direction. As an alternative, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com