One-way valve of manual oil pump

A technology of one-way valve and hand oil pump, which is applied in the direction of control valve, safety valve, balance valve, etc., and can solve problems such as poor sealing effect, poor sealing of oil inlet one-way valve, and loss of sealing effect of one-way valve

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below through embodiment and accompanying drawing:

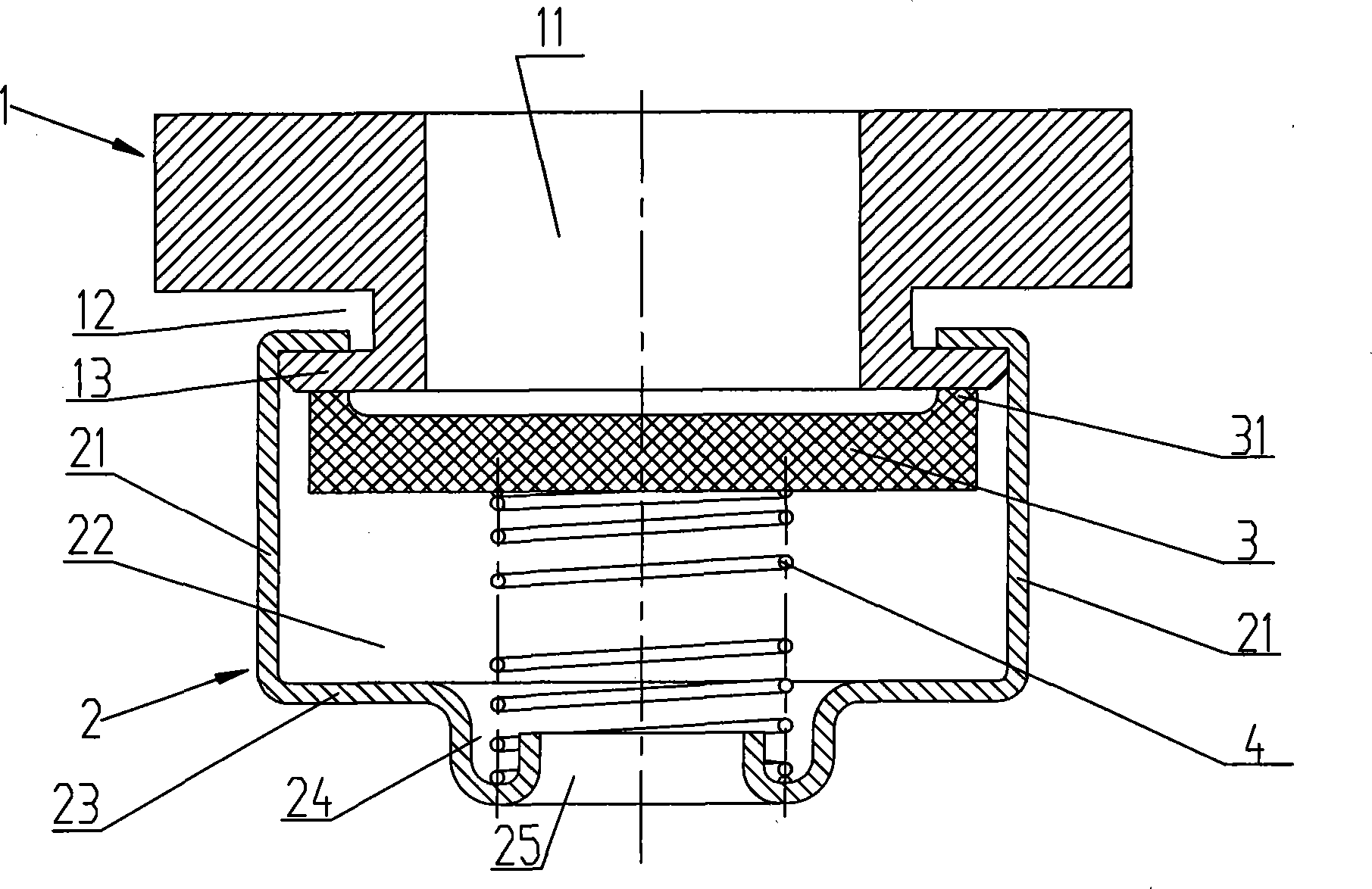

[0022] see figure 1 , The hand oil pump check valve of the present invention includes a valve seat 1 with a circular through valve hole 11 , an outer cover 2 connected to the valve seat 1 , a valve plate 3 , and a spring 4 . The valve seat 1 is a flat circular block, and the through valve hole 11 is located in its central area. One side of the valve seat 1 is a circular boss 13 with an annular groove 12 in the circumferential direction. The outer cover 2 is a circular sheet body 23 with three claws 21 vertically and evenly distributed in the circumferential direction, and a pit 24 and a through hole 25 in the central area. The claws 21 and the pit 24 are respectively located on both sides of the sheet body 23. The through hole 25 Located in the center of the dimple 24 . The outer ends of the jaws 21 are bent and protrude into the groove 12 , so that the cover...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com