Self-adapting contact probe set of multiple-set measurement

A self-adaptive, probe group technology, applied to the parts of electrical measuring instruments, measuring electronics, measuring devices, etc., can solve the problems of large measurement errors and strict sample processing requirements, to eliminate errors, reduce precision requirements, The effect of high measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

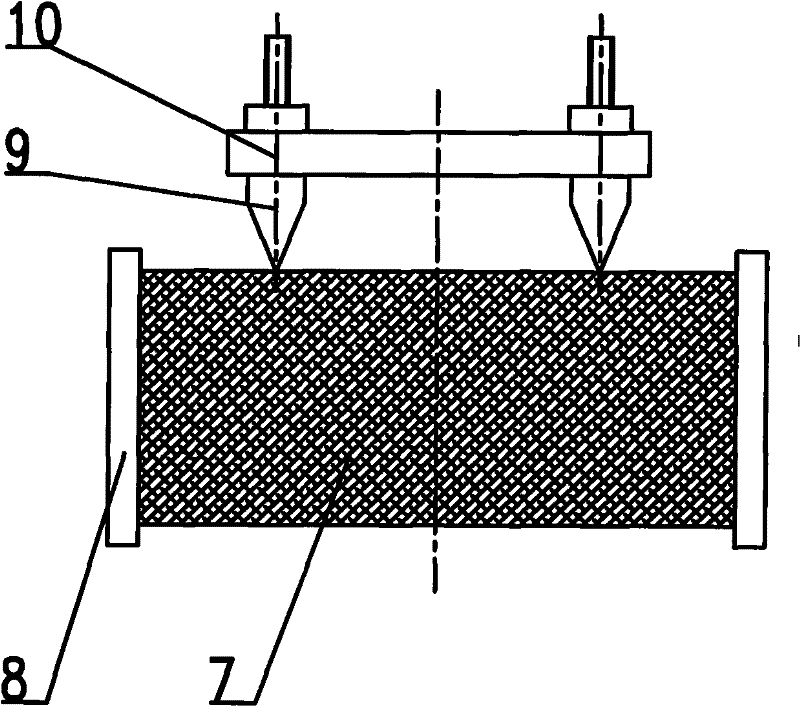

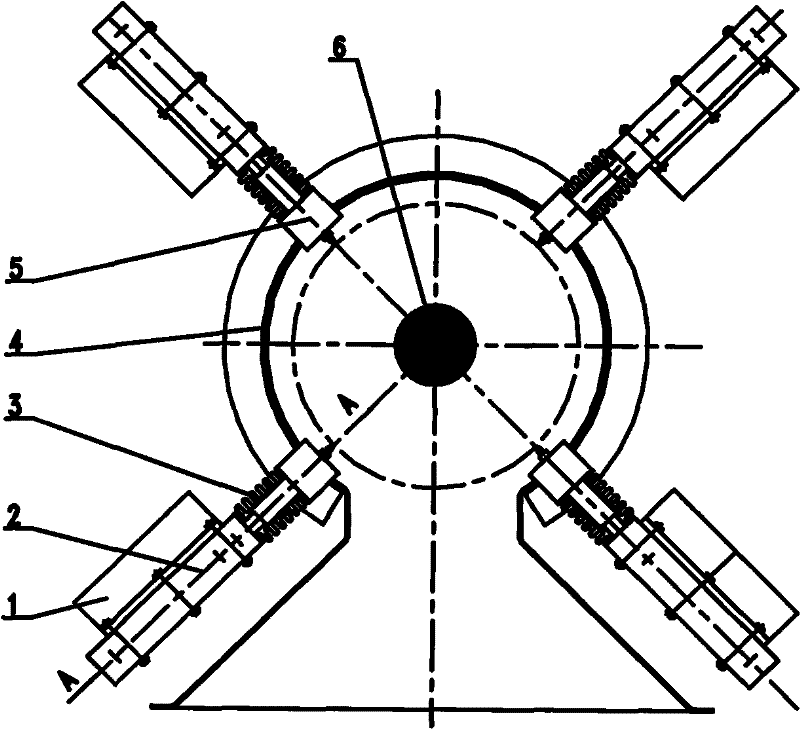

[0025] Such as figure 2 , 3 Shown is a schematic diagram of the probe set of the present invention, and the present invention is described by taking the resistivity measuring device for carbon products for aluminum as an example. The sample to be tested is a cylinder with a diameter of 50 mm and a length of 130 mm.

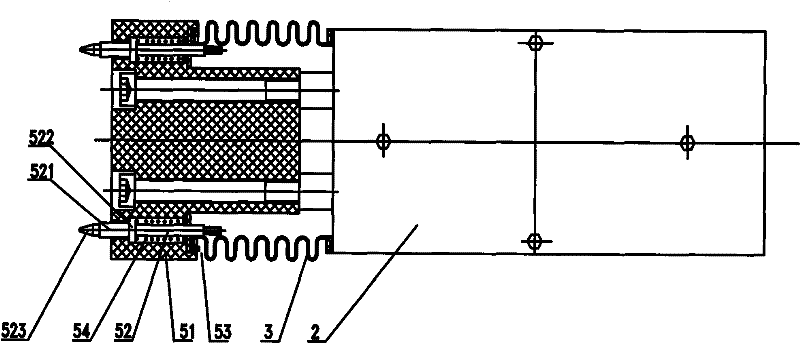

[0026] The self-adaptive contact probe set of multi-group measurement of the present invention comprises four groups of probe assemblies distributed at 90 degrees around the center, each probe assembly includes a probe assembly 5 and a mobile device, and the mobile device in this embodiment adopts The cylinder 2 and the probe assembly 5 are installed on the cylinder 2, and the cylinder 2 can advance and reset towards the center under the action of power.

[0027] It also includes a piston rod dust cover 3, one end of the piston rod dust cover 3 is fixed on the end face of the cylinder 2, and the other end is fixed on the seat body 51. The seat body 51 is made ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com