Cotton stalk puller

A rod pulling machine and cotton technology, applied to harvesters, agricultural machinery and implements, applications, etc., can solve the problems of poor feeding performance, low work efficiency, and non-root removal, and achieve the goal of reducing the power of pulling rods and high work efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

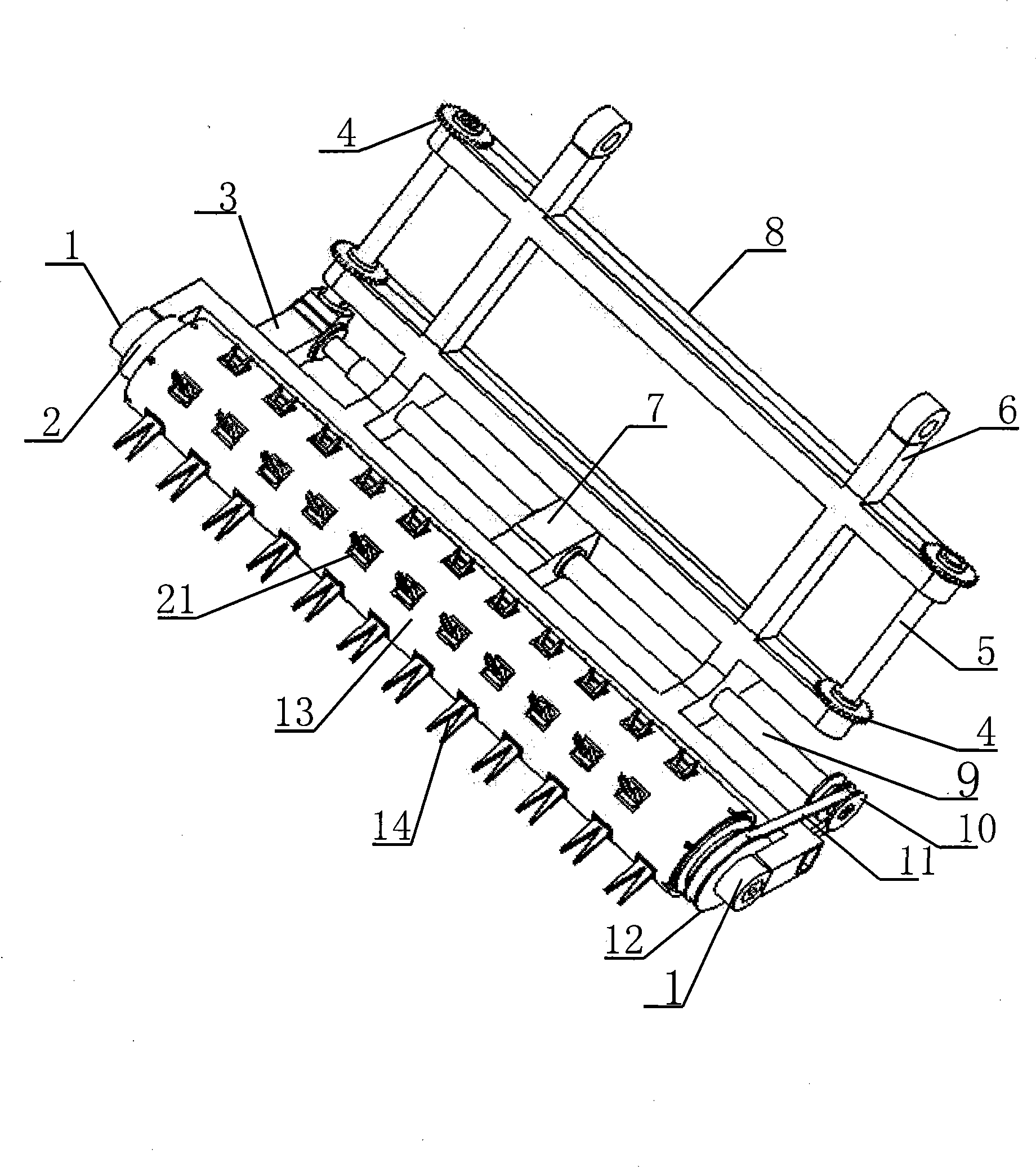

[0018] This cotton stalk pulling machine is made up of frame 6, driving box 7, power transmission shaft 9, transfer box 3, belt pulley 10, cotton stalk lifting device and cotton stalk conveying device. Drive box 7 is installed in the middle part of frame 6, drive shaft 9 is housed on the drive box 7, transfer case 3 is housed on one end of drive shaft 9, and belt pulley 10 is housed at the other end; Adjusting arm 1, install the cotton stalk pulling device on the adjusting arm 1, and connect with the pulley 10 on the transmission shaft 9 through the belt 11; Axis 9 connection (see attached figure 1 ).

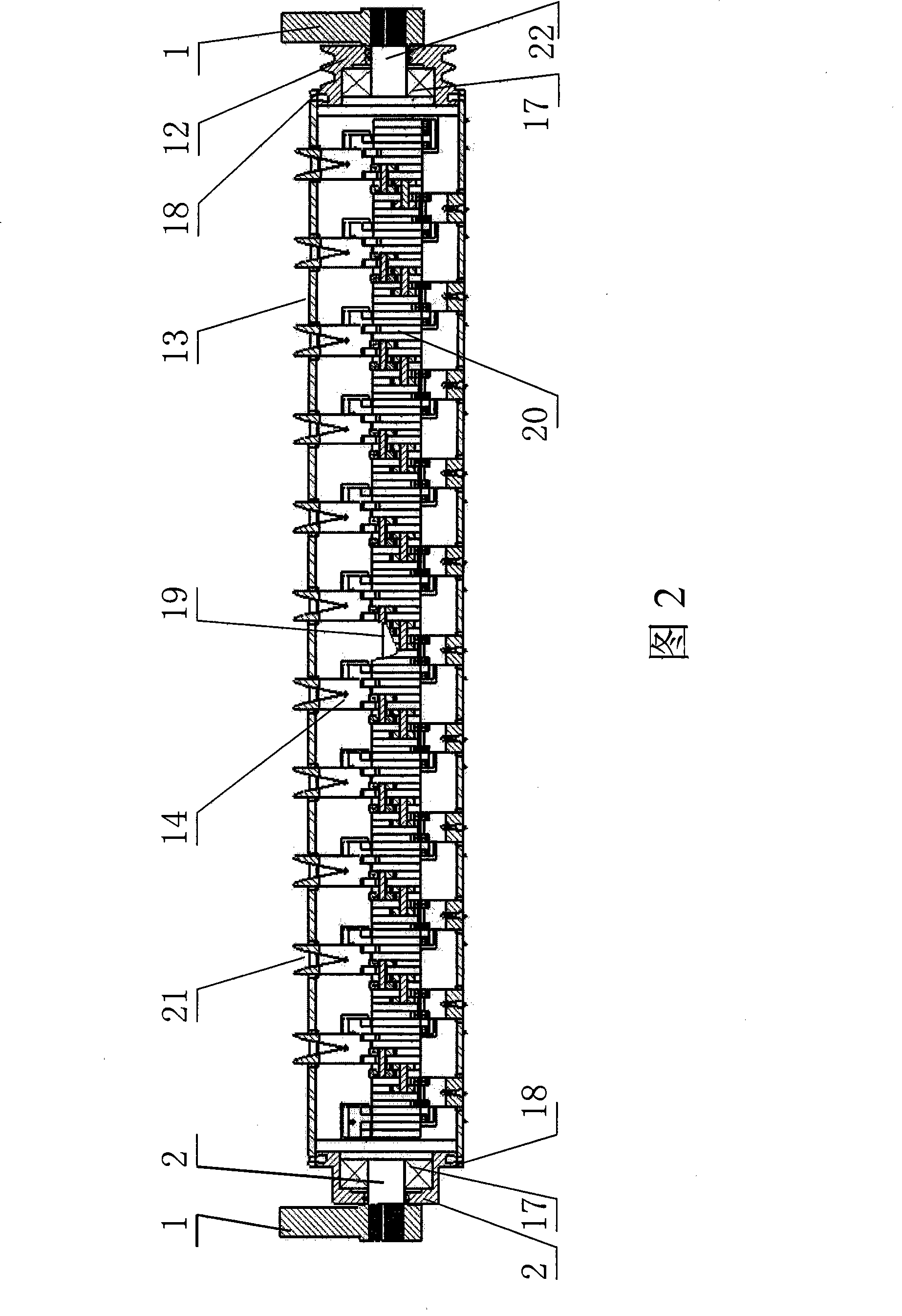

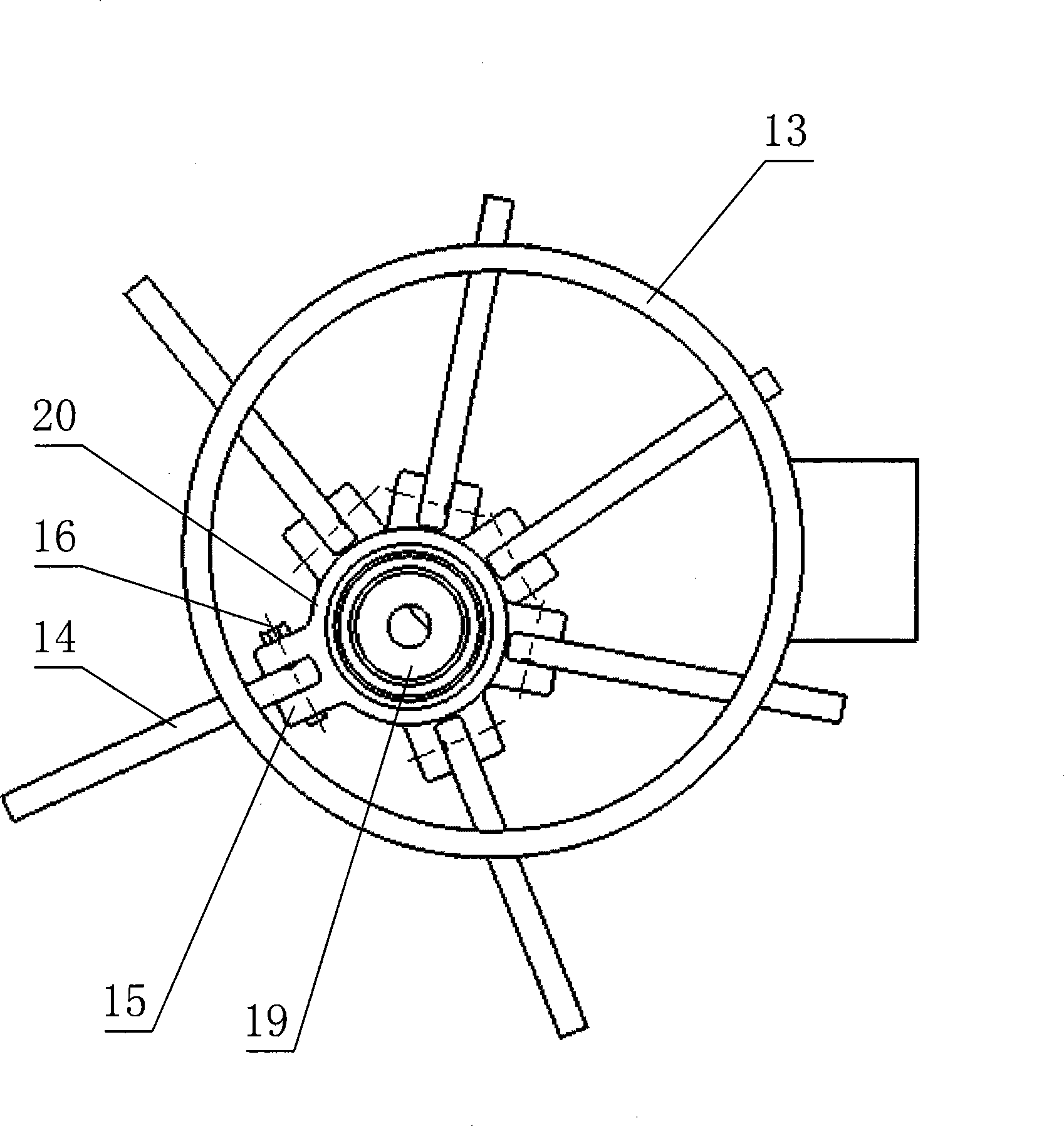

[0019] The cotton stalk lifting device is composed of a drum 13, a fork 14, a fork ring 20, an eccentric shaft 19, a pulley end cover 12, an end cover 2, a power end shaft head 22, and a non-power end shaft head 23; One end of the shaft head 22 and the non-power end shaft head 23 is formed with a spline 25 matching the keyway hole 24 on the installation adjustment arm 1 , and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com