Superfine fiber composite cushion and preparation method thereof

A technology of superfine fibers and production methods, applied in mattresses, melt spinning methods, spring mattresses, etc., can solve the problems of human skin irritation, poor anti-leakage effect, poor washing effect, etc., to achieve soft texture, Easy to carry, no hardening after washing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

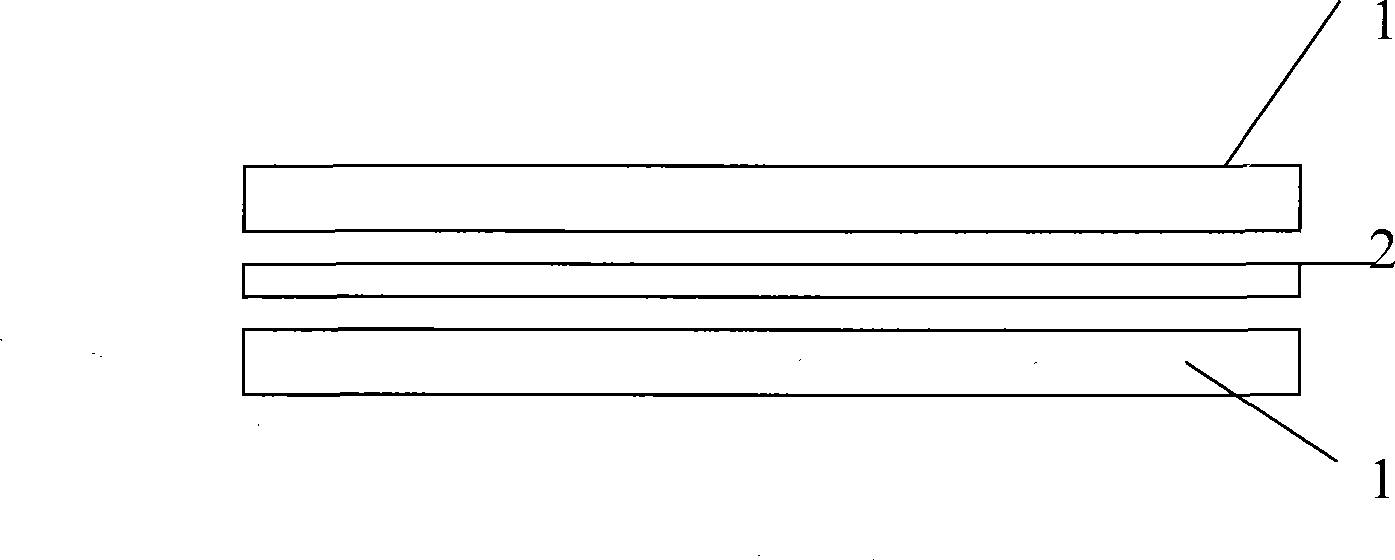

[0026] figure 1 It is a schematic diagram of the exploded structure of the mattress of the present invention. The mattress pad of the present invention is divided into upper and lower layers and an intermediate layer. The upper and lower layers are superfine fiber composite layers, which are woven from superfine fiber composite yarns. The weight ratio of superfine fiber composite yarns is 70-80% polyester and 20-30% nylon, the middle layer is a breathable and leak-proof film.

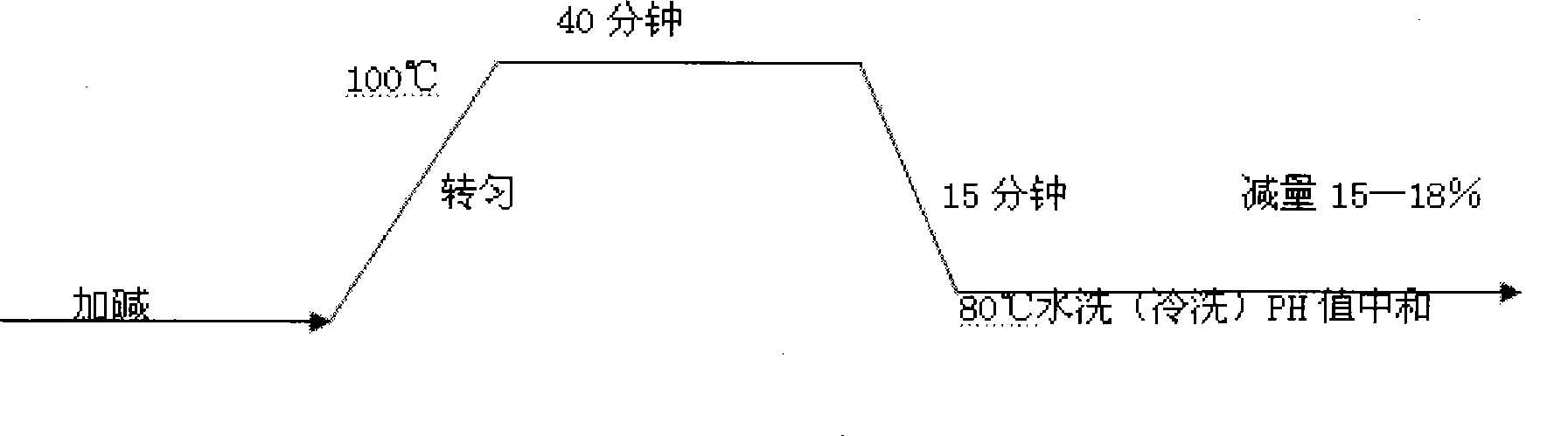

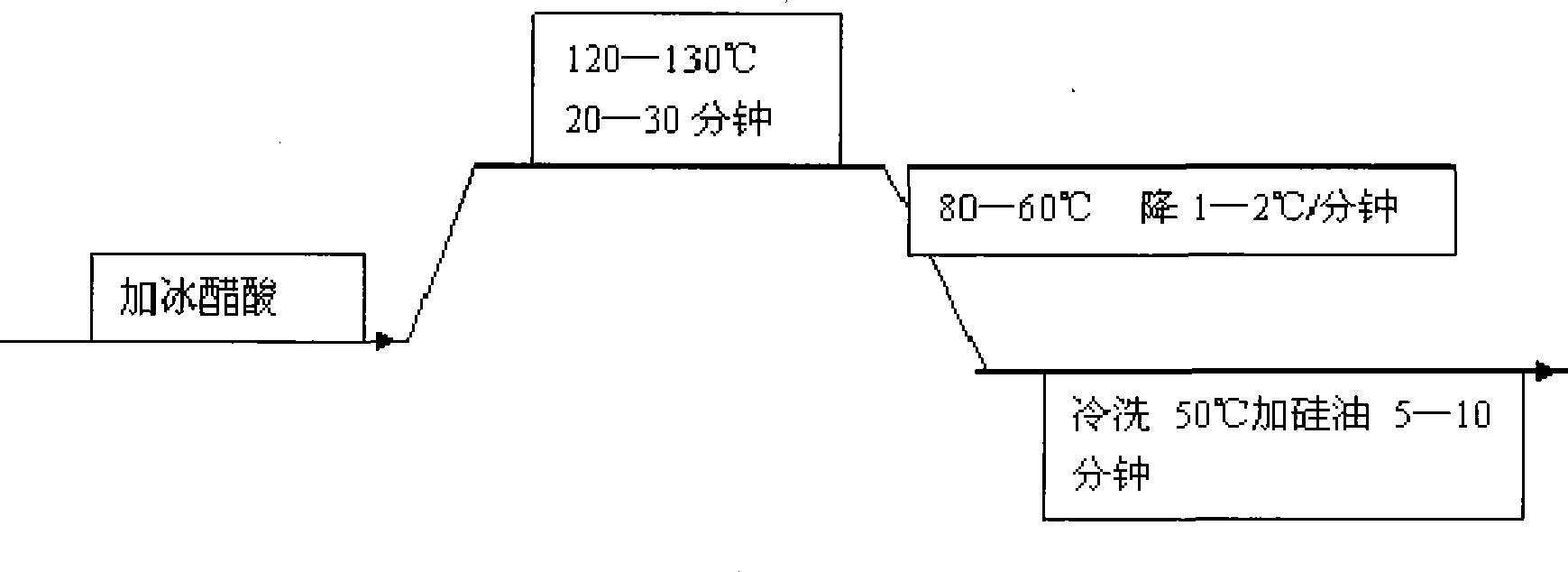

[0027] The manufacturing method of the mattress of the present invention will be introduced in detail below.

[0028] 1. The raw materials used in the present invention are polyester and nylon slices imported from South Korea, which are converted into liquid at a high temperature of 292°C-294°C, and then passed through a German 150D / 72F×16P or 160D / 72F×16P spinneret, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com