Biomass gasification device and gasification technology

A biomass and gas purification device technology, applied in the petroleum industry, special dry distillation, coke ovens, etc., can solve the problems of reduced working efficiency of air compressors, reduced gasification efficiency of devices, and heavy installation and maintenance workload, etc., to achieve gas Stable and reliable process, reduced maintenance cost, and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

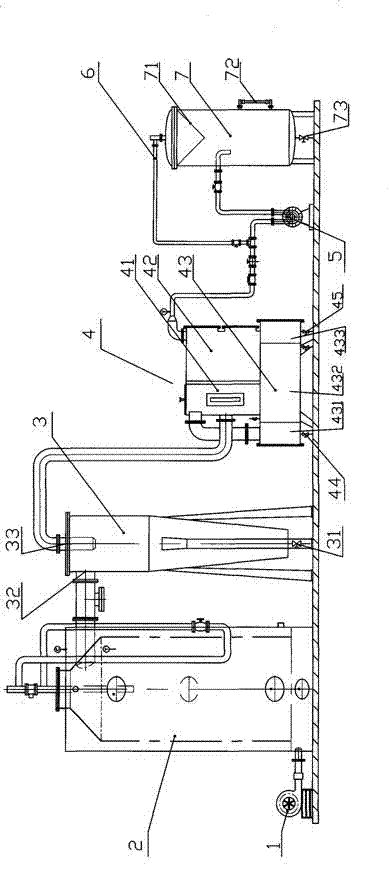

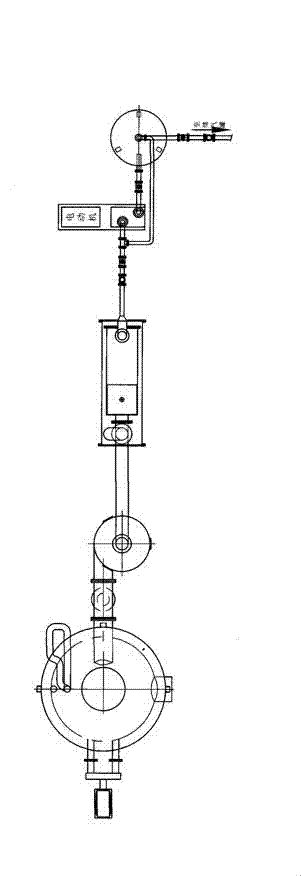

[0048] Biomass gasification equipment, such as figure 1 , figure 2 As shown, it includes a blower 1, a gas generator 2, a cyclone separator 3, a composite filter device 4, a water ring compressor 5, a gas-water separator 7 and a pressure vessel connected in sequence by a gas pipeline, and the pressure vessel is then decompressed After the valve is depressurized, it is connected to the gas pipeline network at the user end; in order to ensure the normal operation of the water ring compressor, it is also equipped with a pressure balance pipe 6, and one end of the pressure balance pipe 6 is connected to the gas pipeline at the inlet end of the water ring compressor 5 Road, the other end is connected to the gas pipeline of the gas outlet of the gas-water separator 7.

[0049] The cyclone separator 3 is a hollow rotary body structure, including two parts connected up and down, the upper part is a hollow cylinder, and the lower part is a hollow rounded table body, which is thick at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com