Control device for flying tension and flying time of weft of air jet loom and control method thereof

A control device and time-of-flight technology, applied to looms, textiles, papermaking, textiles, etc., can solve the problems of reduced traction, restrained weft breakage during flight, increased air consumption, etc., to reduce the level of weft tension and prolong the time , Reduce the effect of weft breaking rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

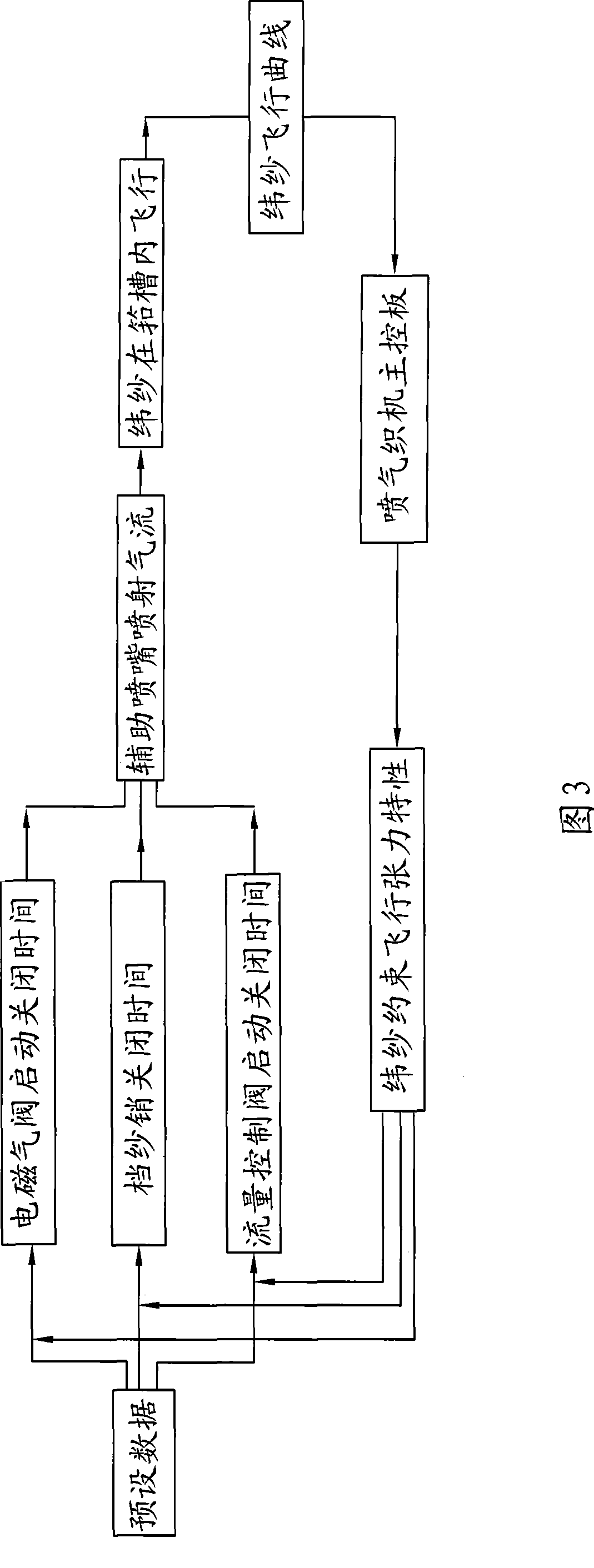

[0020] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

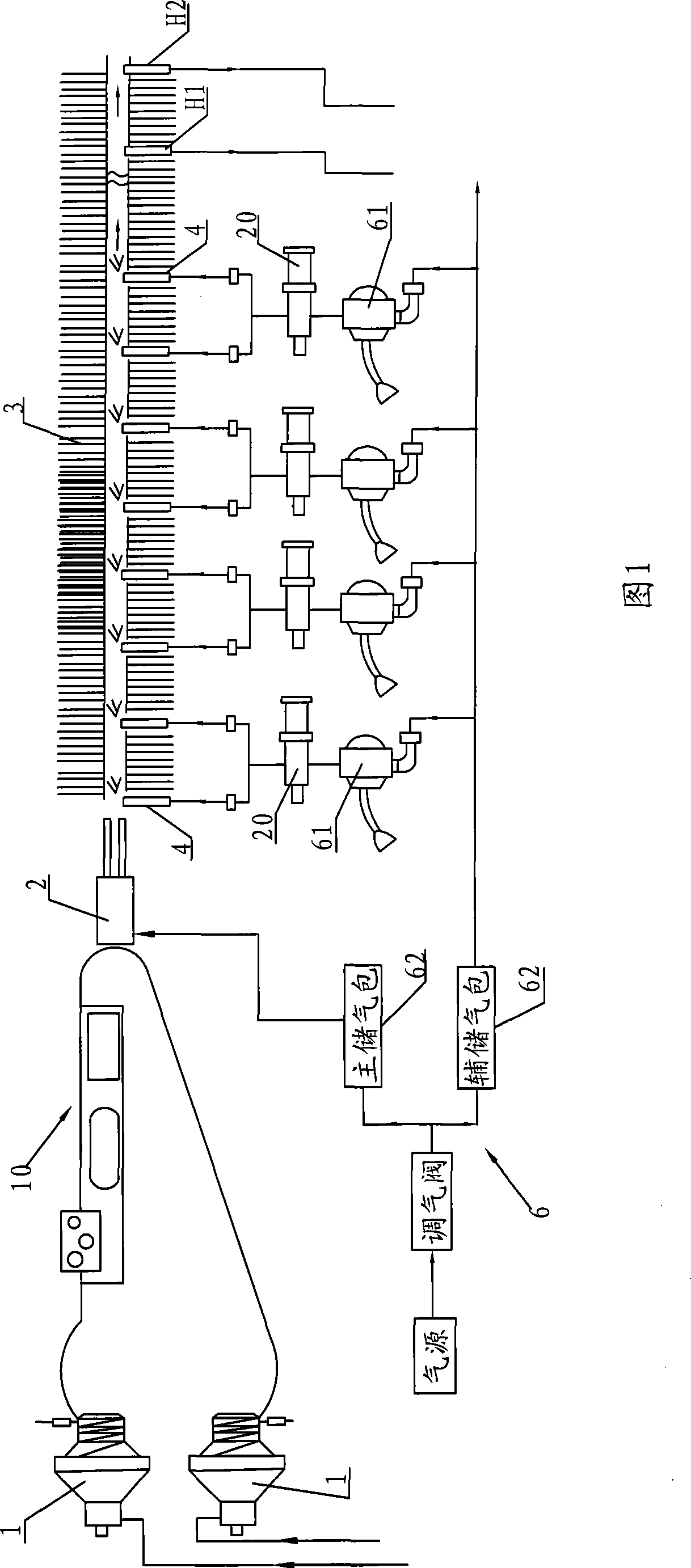

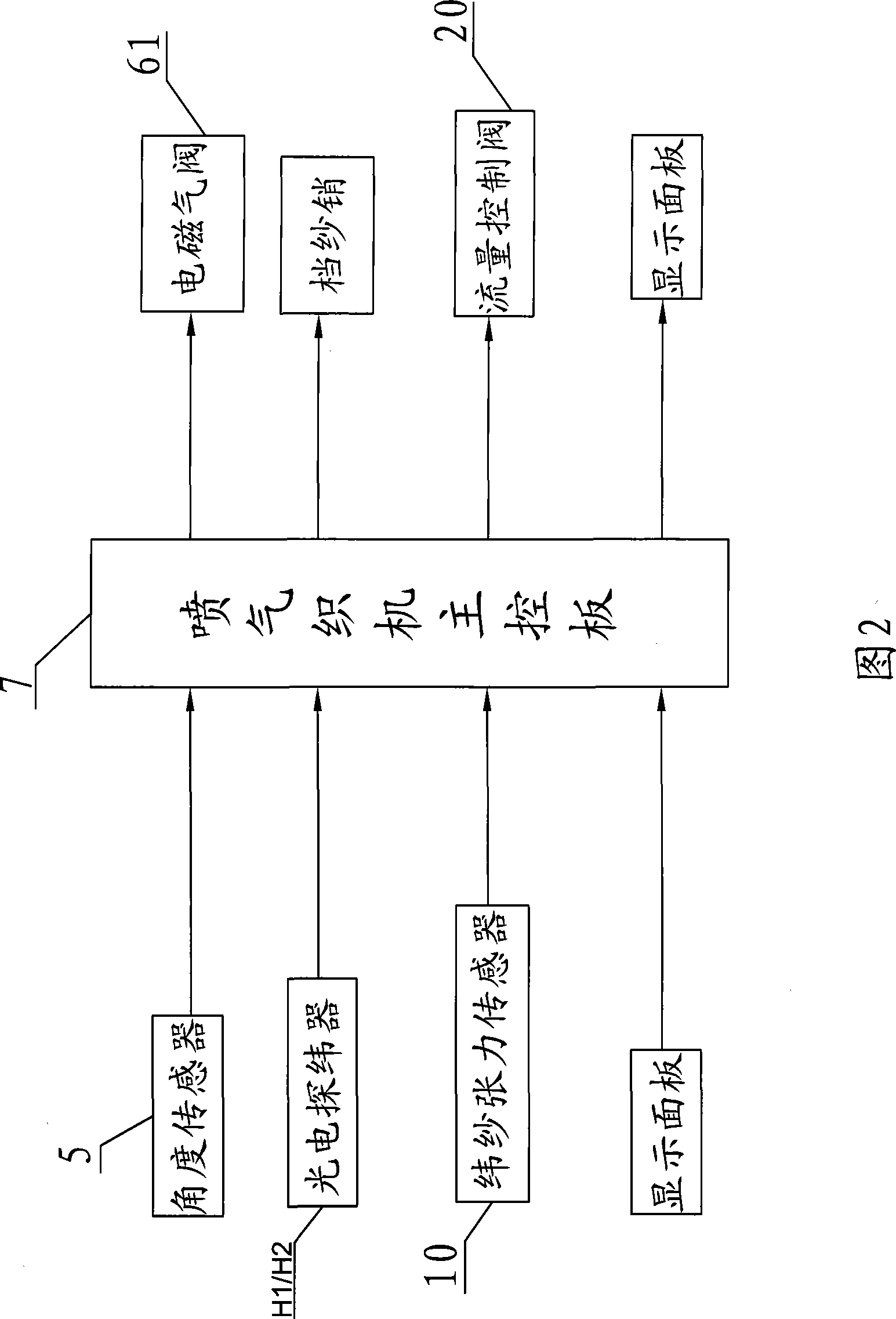

[0021] Air-jet loom weft insertion system as shown in Figure 1, it comprises the weft feeder 1 that is provided with retainer pin, main nozzle 2, special-shaped reed 3, a plurality of auxiliary nozzles 4 that are arranged along the reed width of special-shaped reed 3, The angle sensor 5 used to collect the angle signal of the main shaft of the air-jet loom, the photoelectric weft detector H1 and H2 arranged along the 3 reed widths of the special-shaped reed to collect the time when the weft yarn at the corresponding position reaches the weft catching side, are used for the described The main nozzle 2 and the auxiliary nozzle 4 provide the air supply mechanism 6 of the air source and the main control panel 7 of the air-jet loom (not shown in the figure), the main nozzle 2 is facing the shed direction, and the auxiliary nozzles 4 are distribut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com