Porous impact type fly ash sampler

An impact type sampler technology, applied in the field of porous impact type fly ash sampler, can solve the problems of poor sampling effect, limited opening size, and poor sample representativeness, so as to improve the monitoring effect, meet the use requirements, and expand the acceptance area effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

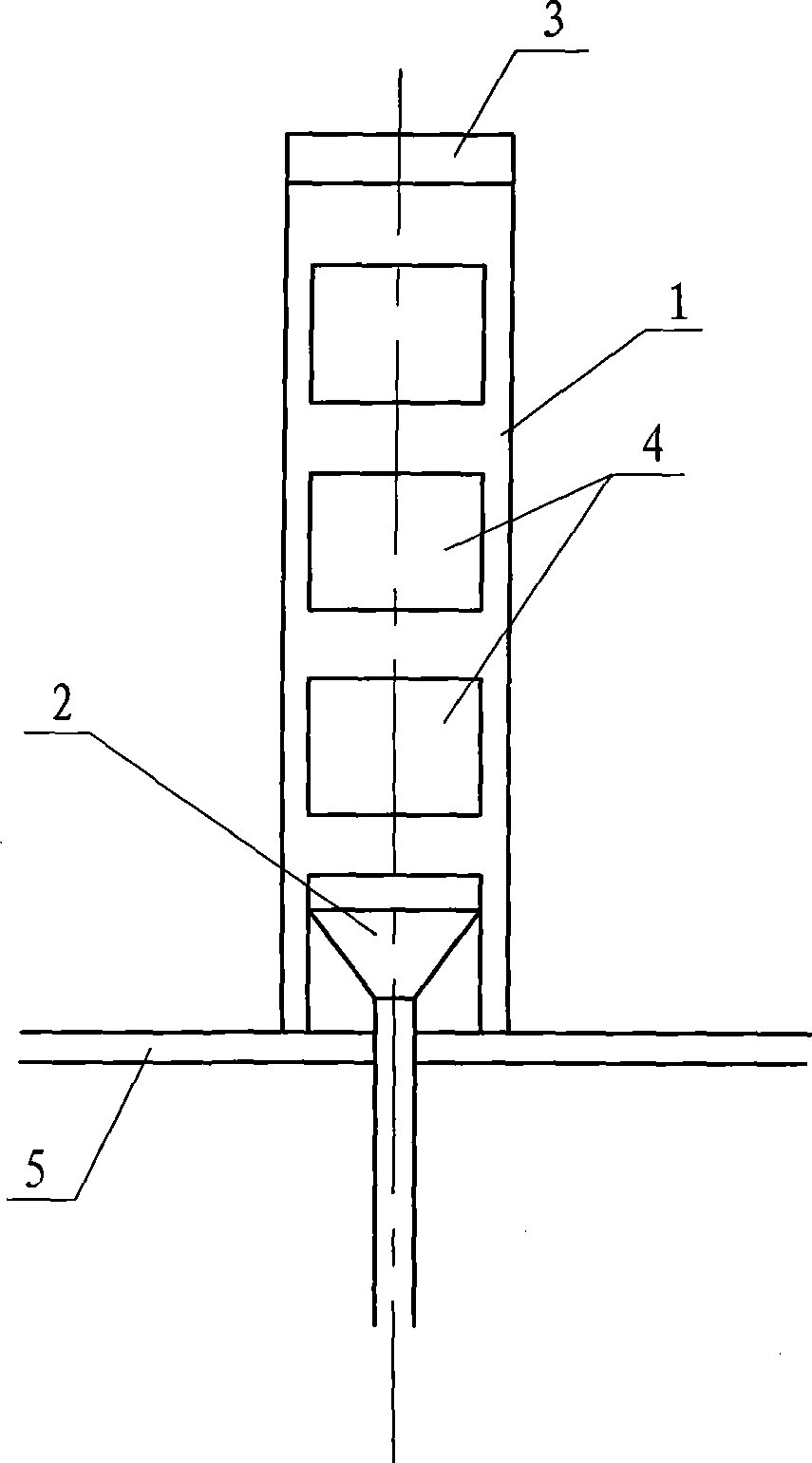

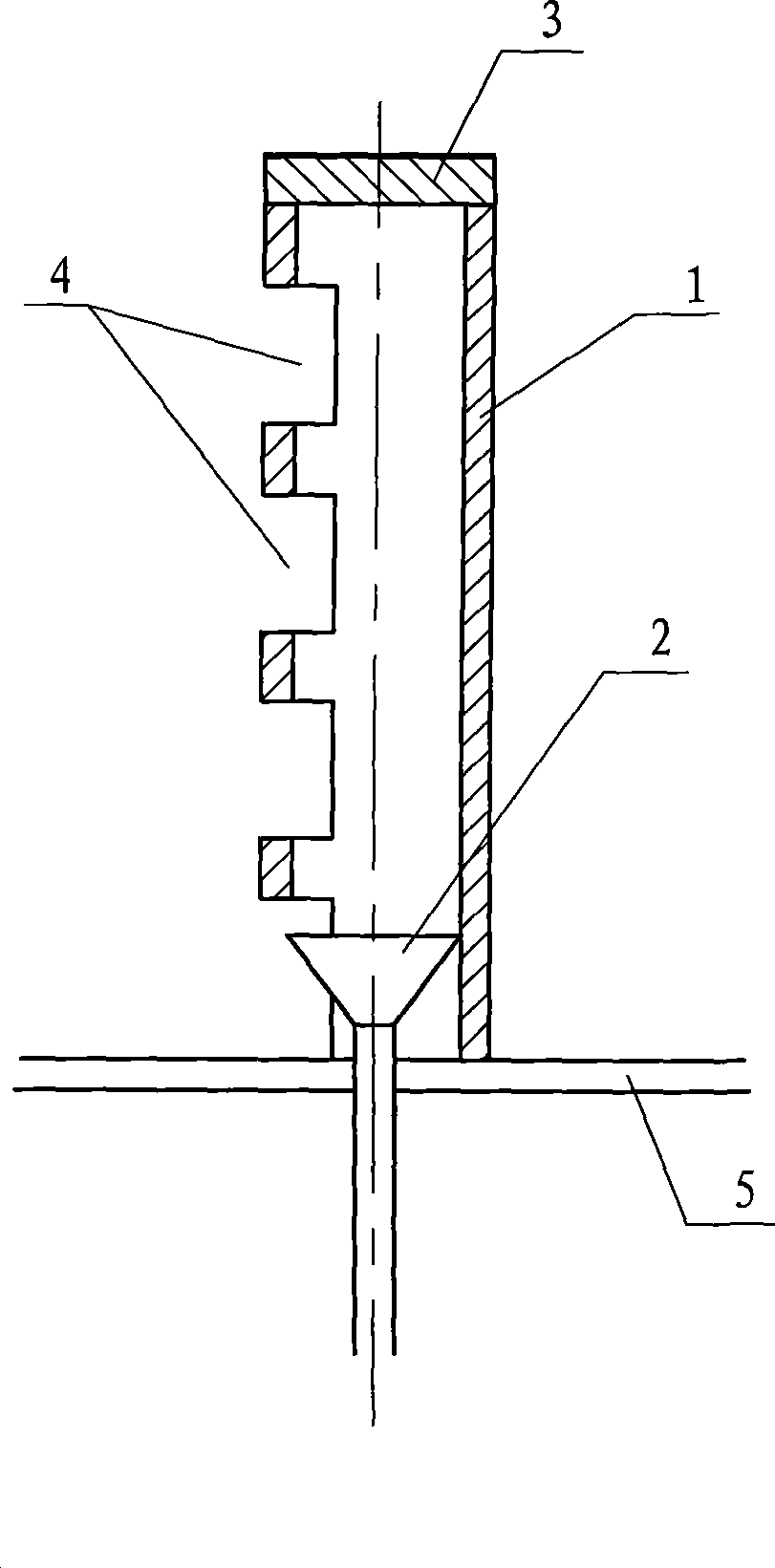

[0009] Such as figure 1 and figure 2 As shown, the porous impact fly ash sampler of the present invention comprises a pipe body 1 vertically welded in the flue 5, and a funnel 2 connected with an external ash pipe is installed at the bottom end of the pipe body 1; the pipe body 1 Closed by the cover plate 3, a plurality of rectangular sampling windows 4 are opened from top to bottom on the side of the pipe body facing the flue gas flow.

[0010] When in use, the flue gas flow enters the pipe body 1 from the sampling window 4, hits the pipe wall, and the fly ash falls into the funnel 2 and enters the ash guide pipe.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com