Chain drive hydraulic brick receiving machine

A technology of chain drive and transmission mechanism, applied in the field of chain drive hydraulic brick connecting machine, can solve the problems of perfect pallet design and inconvenient brick picking process, and achieve the effect of reducing labor intensity of workers, convenient control and height reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

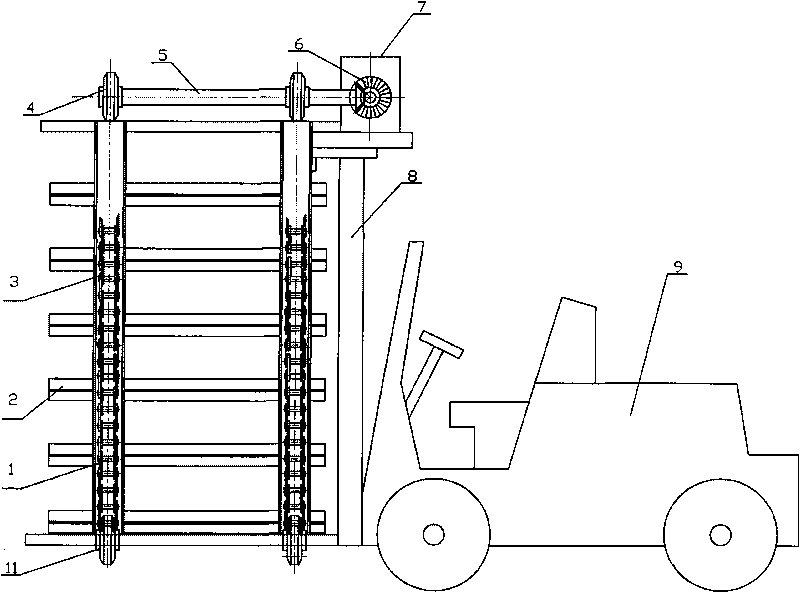

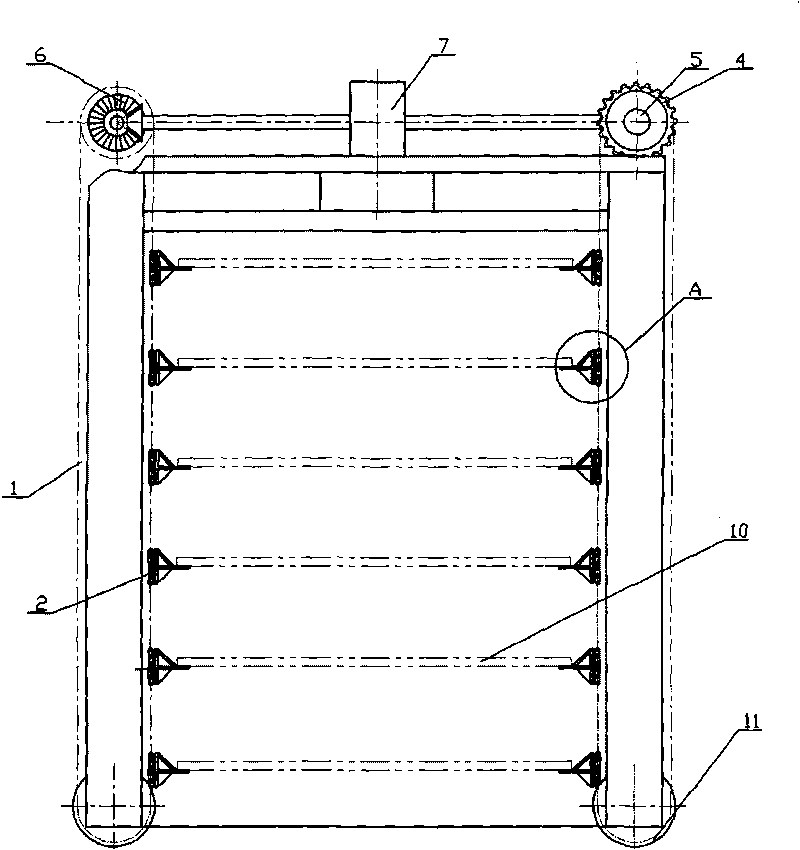

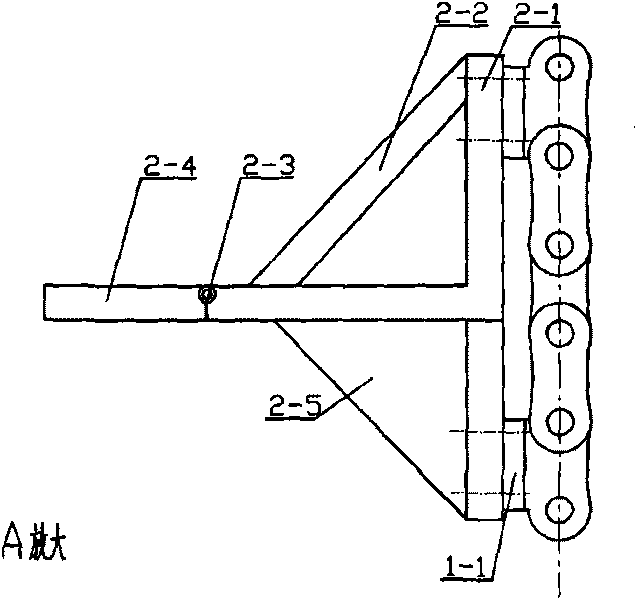

[0029] Such as figure 1 , figure 2 As shown, according to the chain drive hydraulic brick connecting machine of the present invention, comprising a hydraulic hairpin car 9 and a brick supporting plate 10, it is characterized in that a brick connecting mechanism is fixedly connected in front of the hydraulic hairpin car, and the top of the brick connecting mechanism is set There is a hydraulic system 7 and a transmission mechanism, the hydraulic system 7 is connected with the hydraulic cylinder of the hydraulic hairpin car 9, the hydraulic system 7 is connected with the transmission mechanism, and the described brick connection mechanism includes a steel frame 8, Four groups of U-shaped chain guard grooves 3 arranged on the four corners of the steel structure frame 8, four hanging chains 1 arranged in the four groups of U-shaped chain gua...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com