Compound rope of cable rope and optical cable

A composite cable and optical cable technology, applied in the direction of communication cables, cables, circuits, etc., can solve the problems of unstable cable transmission performance, affecting transmission distance, uneven impedance, etc., to improve transmission stability, increase transmission capacity, and suppress mutual interference effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

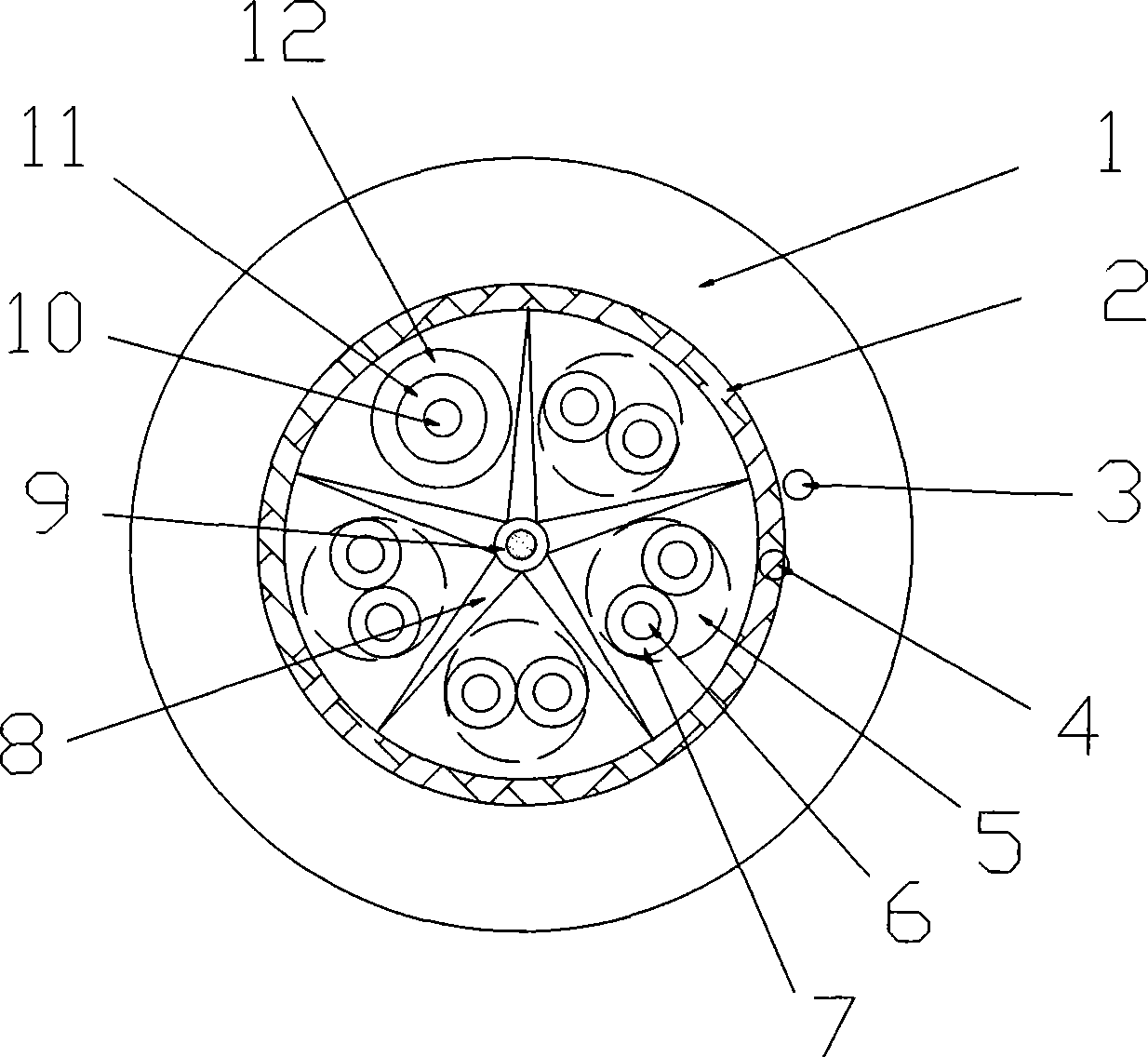

Embodiment 1

[0025] A composite cable of an electric cable and an optical cable, including a twisted wire core and an optical fiber core. The composite cable has a skeleton 8, and the center of the skeleton 8 has a high Young's modulus fiber aramid yarn 9. The stranded wire core and the optical fiber core 10 are placed in the skeleton groove. The optical fiber core is covered with a tight sleeve, the optical fiber core 10 is covered with a polyester sheath 11 , and the outer covering is covered with a fiber sheath 12 . There is a shielding layer 2 on the outside of the stranded wire core and the optical fiber core, and the shielding layer 2 is a braided structure of aluminum-plastic composite tape and copper wire. The shielding layer is provided with a tinned drain wire 4 . The stranded core conductor has a sheathing insulation layer 7 . The twisted wire core is composed of four wire pairs 5, the wire pair 5 is formed by twisting two separate insulated conductors, the twisting pitch is ...

Embodiment 2

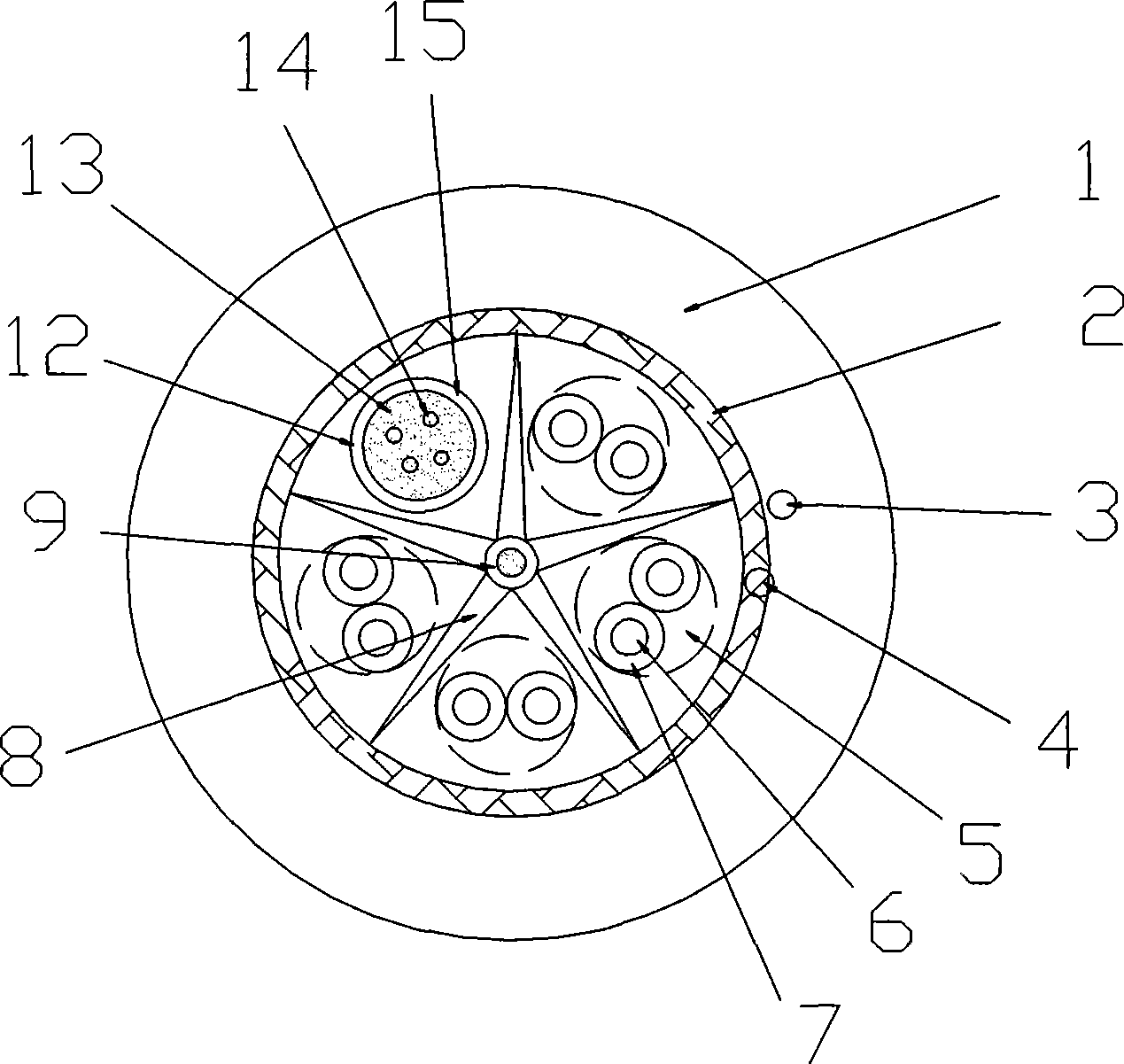

[0027] The optical fiber core in the composite cable of the cable and the optical cable is covered with a loose tube, and there is a filling ointment 13 between the optical fiber cores 14 in the loose tube, and an optical fiber sheath 15 outside. Others are the same as embodiment 1.

[0028] refer to figure 1 and figure 2 . The specific structure of the composite cable of the cable and the optical cable is composed of four wire pairs and an optical cable core. The cable wire can be composed of more than four wire pairs, and the optical cable core can be more than one. The outer conductor is covered with a polyolefin insulation layer. The wire pair The cable core is embedded with a reinforced core skeleton to form a cable core, and the outer shield covered with aluminum-plastic composite tape and braided copper wire is added. The outer shield is covered with an outer sheath. The twisted pitch of the wire pair group is 10.5mm-21.5mm, for matching. The skeleton is made of hi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| distance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com