Edge detection method of color textile texture image oriented to textile industry

A texture image and edge detection technology, applied in image analysis, image data processing, instruments, etc., can solve the problems of difficult edges of artistic patterns, loss of color component correlation, etc., to improve edge detection accuracy and eliminate texture noise interference.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

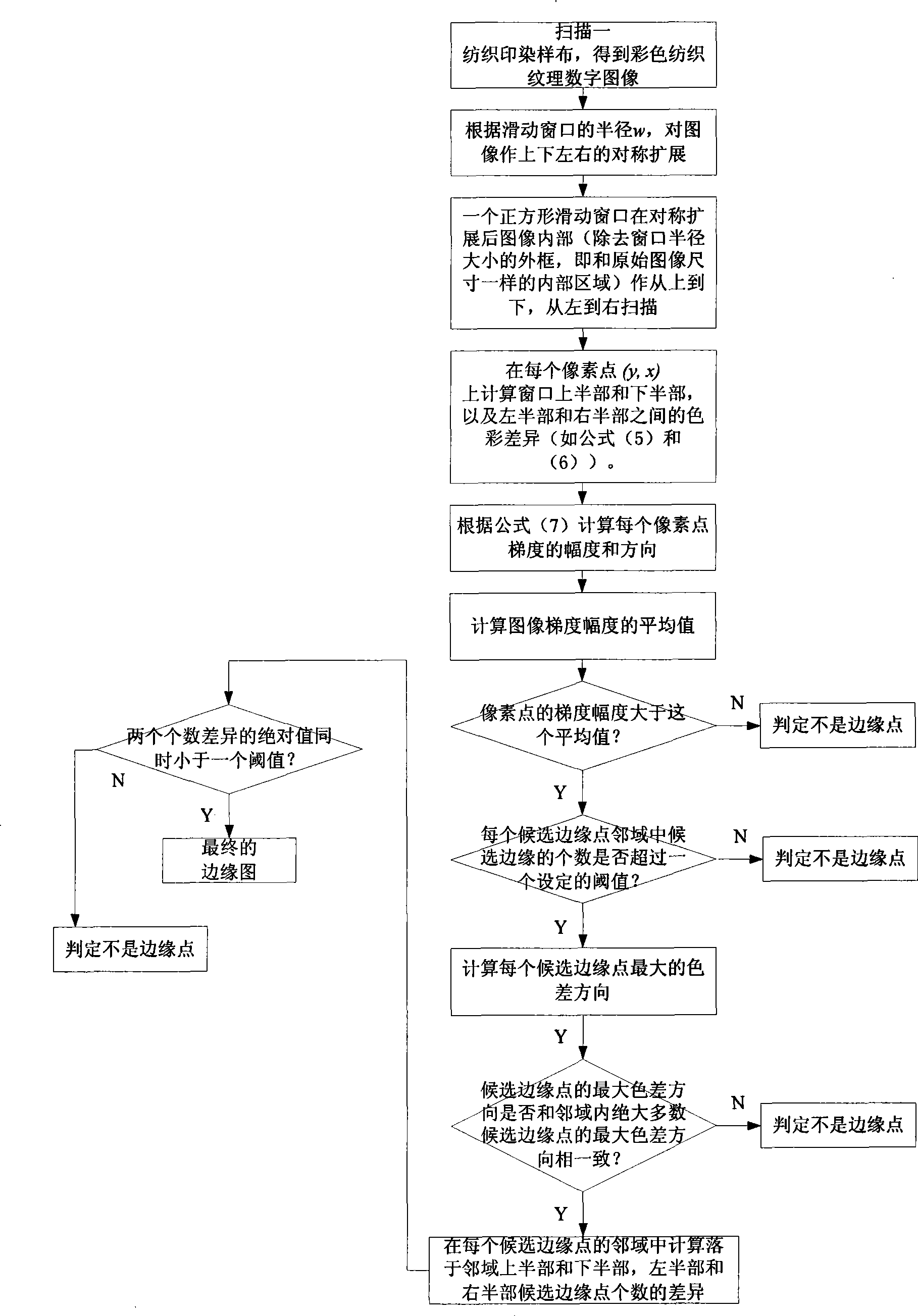

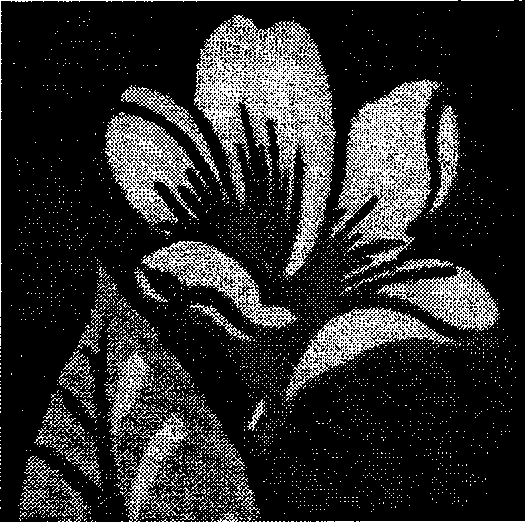

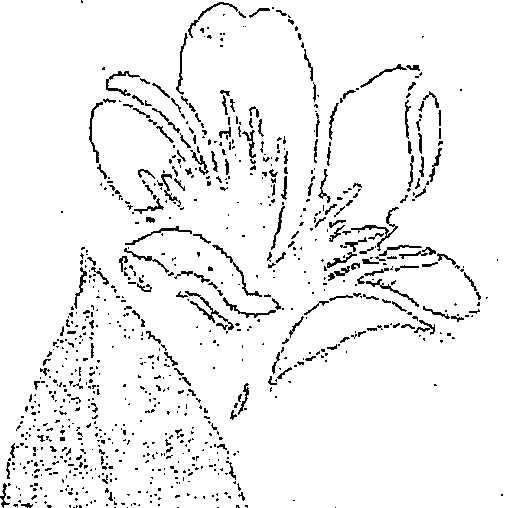

[0033] Embodiment 1, with reference to attached figure 1 , take the following steps for Figure 2-a Do edge detection:

[0034] (1) scan as Figure 2-a The color textile printing and dyeing sample cloth shown, obtains the digital image of color textile texture;

[0035] (2) Here, the sliding neighborhood window is a square. According to the window radius w set by the user, generally the value is 2, and the image is expanded symmetrically up, down, left, and right. The width and height of the input image are Width and Height respectively, then the expansion After the width and height of the image become Width+2w and Height+2w, the row of the image can be expanded symmetrically first, and then the column can be expanded symmetrically, namely

[0036] I row - ext c ( i , j ) = ...

Embodiment 2

[0076] Adopt the same step as embodiment 1 to attach Figure 3-a For detection, the detected image edge map is shown in the attached Figure 3-f , combined with Figure 3-b , Figure 3-c , Figure 3-d , Figure 3-e , to verify again: the result of applying the present invention to detect is obviously due to the result of the traditional edge detection method.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com