Device and method for producing granules from a polymer melt

A melt and plastic technology, which is applied in the field of devices and processing of particles produced from plastic melt, can solve the problems of risk output pipeline blockage, longer holding time, excessive cooling effect, etc., and achieve cost-effective and reliable production effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

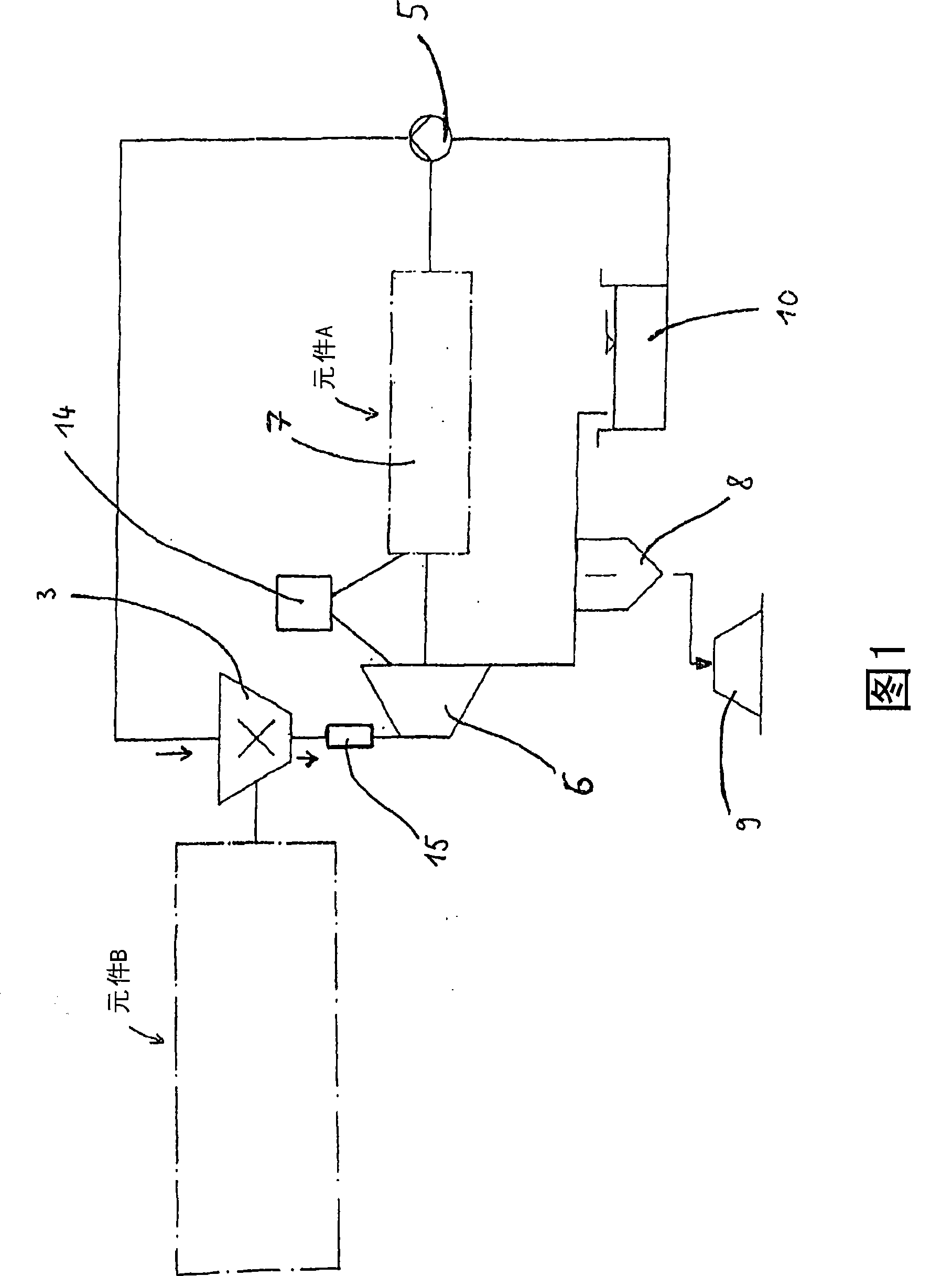

[0046] Fig. 1 shows a schematic diagram of a system structure with an apparatus for particle production according to an embodiment of the present invention.

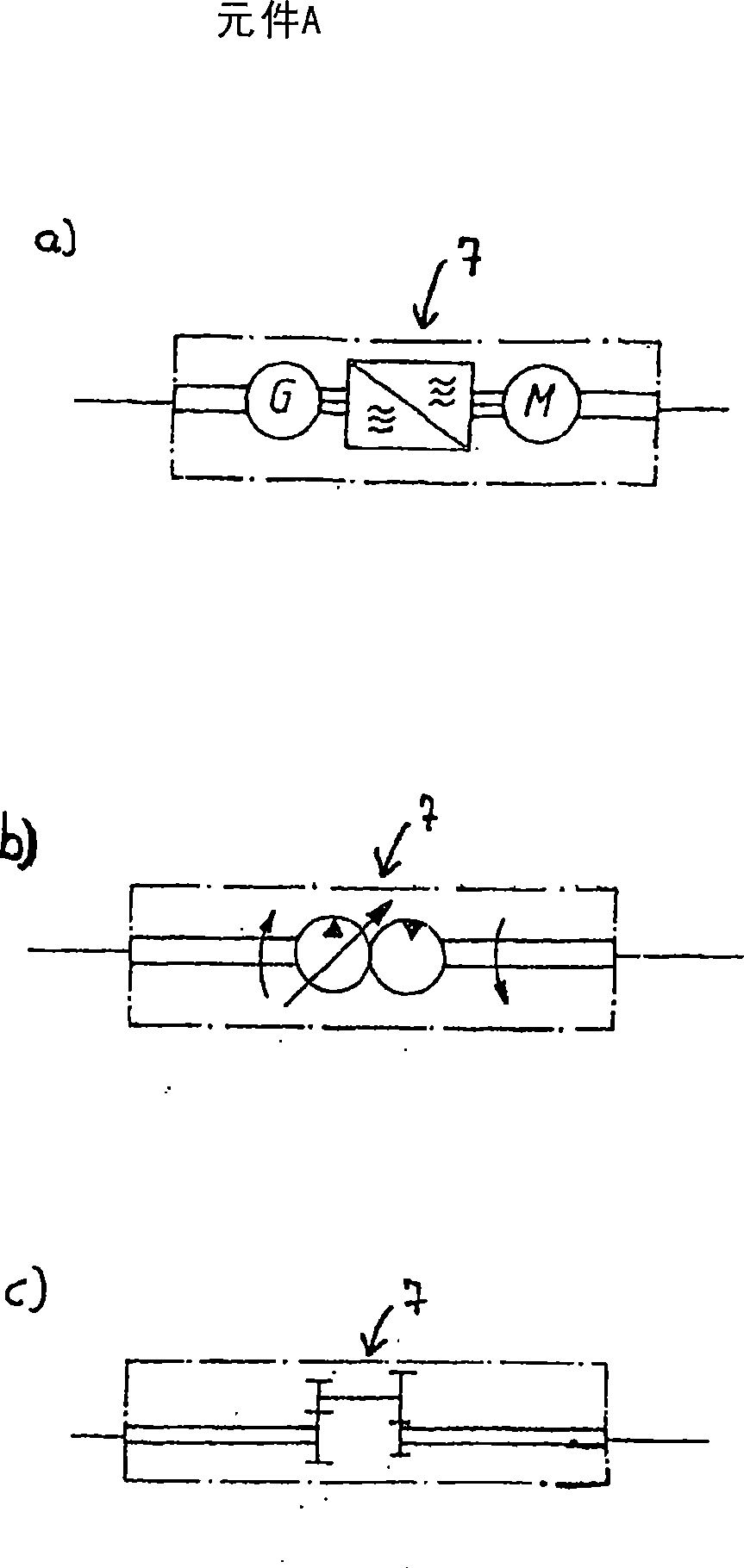

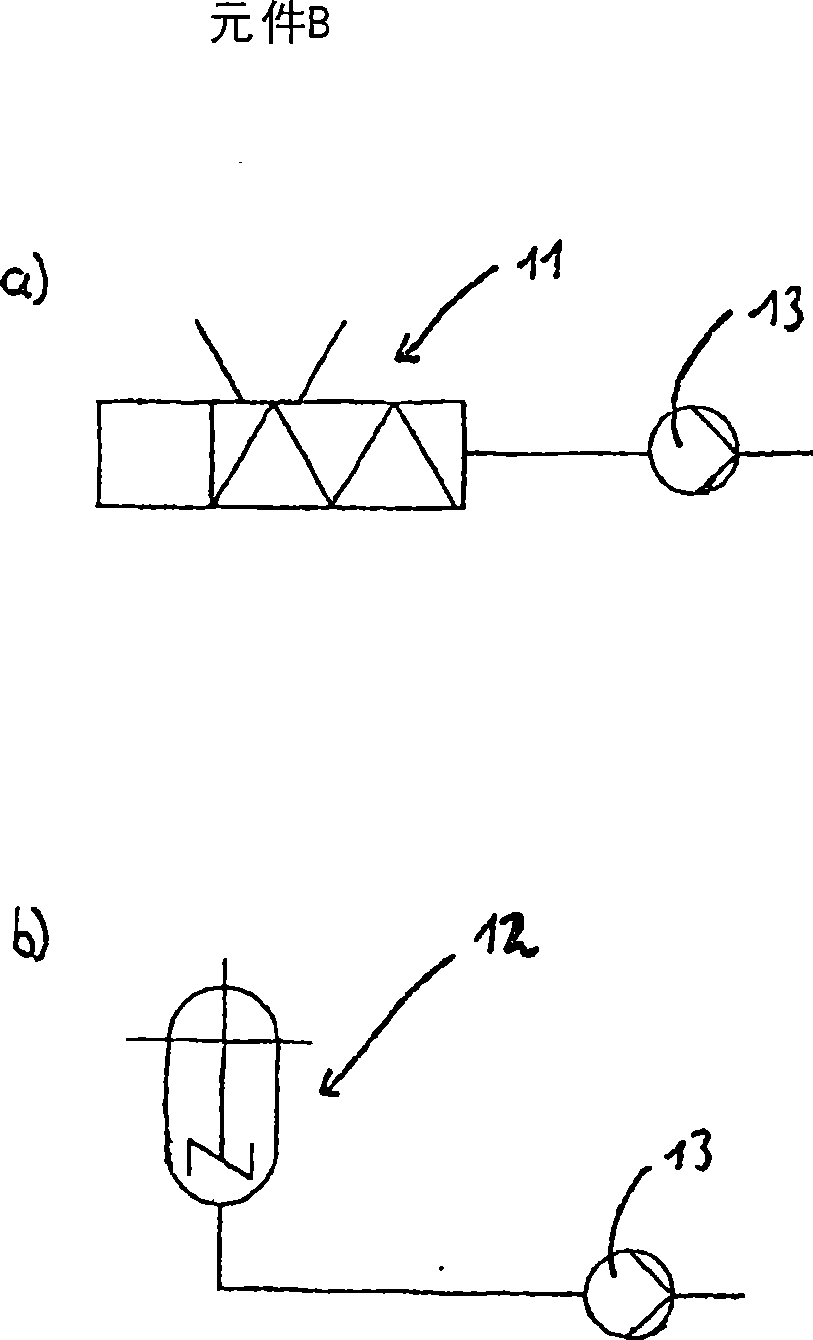

[0047] Pass component B in Figure 1 (component B will refer to image 3 In further detail) represented by the plastic melt supply device, the plastic melt to be granulated is supplied to the granulation area, that is, supplied to the shredding device represented by the reference number 3 in FIG. 1. The embodiment of the shredding device 3 will refer to Figure 7 Describe in further detail. After being cut into individual pellets in the shredding device 3 or in the shredding device 3, the plastic melt then enters the treatment fluid 4 (not explicitly shown in FIG. 1), and only the flow direction of the treatment fluid is shown by the arrow , Wherein the treatment fluid is supplied to the treatment chamber 2 (not shown in FIG. 1) or to the shredding device 3 by the upstream pumping device 5, which is usually a pump, at a pressu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com