Low shrinkage epoxy-cationic curable compositions

A technology of cationic compound and epoxy composition, applied in the field of low-shrinkage epoxy cationic curable composition

- Summary

- Abstract

- Description

- Claims

- Application Information

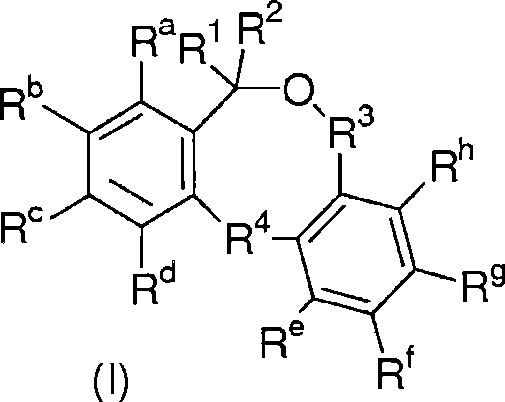

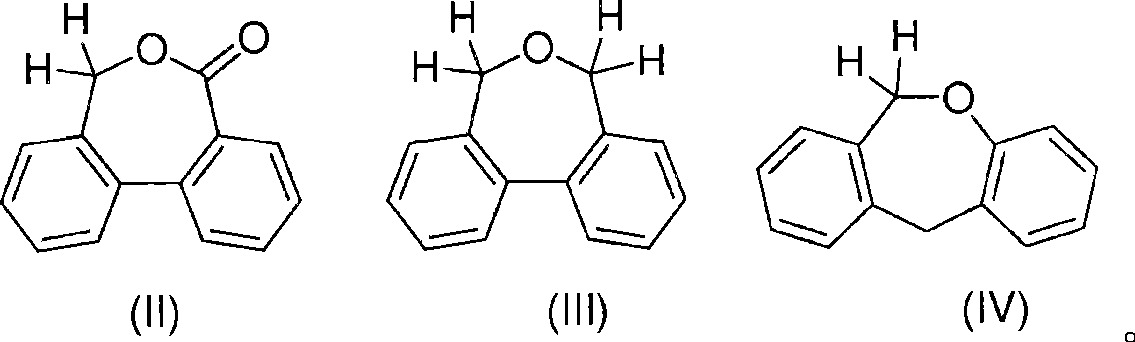

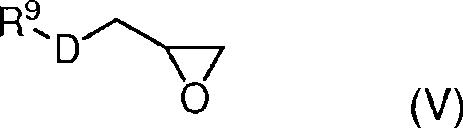

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-1

[0138] Preparation of Curable Formulations

[0139] Bis F-DGE (8.00 g, 25.6 mmol, amount of epoxy groups = 51.2 mmol), DBOX (2.52 g, 12.0 mmol) and tetraphenylethylene glycol (25 mg) were mixed at 110° C. and removed under vacuum. gas to obtain a homogeneous mixture. After cooling to room temperature, HD7980 (diaryliodonium hexafluorophosphate, 50 mg) was added to the mixture to give the corresponding curable formulation A as a homogeneous liquid.

[0140]

[0141] Curing Reaction and Shrinkage Test

[0142] About 5 g of mixture A obtained was used to measure its volume by gas-pychnometer. From the weight and volume of the sample, calculate its uncured density (=D 固化前 ). Three independent samples were used for the test, and each sample was tested 5 times to calculate the average density (D 固化前 ). Calculated D 固化前 It is 1.216. Then, the mixture was transferred into a silicone rubber mold and cured at 110°C for 2 hours, followed by post-curing at 140°C for 1 hour to o...

Embodiment 1-1-a

[0147] Preparation of Curable Formulations

[0148] Powdered DBOX (2.00 g, 9.51 mmol) was dispersed in Bis F-DGE (8.00 g, 25.6 mmol, amount of epoxy groups = 51.2 mmol). Tetraphenylethylene glycol (25 mg) and HD7980 (diaryliodonium hexafluorophosphate, 50 mg) were added to the resulting DBOX / BisF-DGE dispersion to obtain a heterogeneous preparation, which was used in Cured under the same conditions as Example 1-1.

[0149]

[0150] Curing reaction and shrinkage test were performed in the same manner as in Example 1-1.

[0151] As shown in Table 1, there is no difference in the degree of shrinkage between Example 1-1-a and Example 1-1, which shows that the addition of powdered DBOX that is not dissolved in the epoxy resin is equally effective in inhibiting their volume shrinkage.

Embodiment 1-1-b

[0153] Preparation of Curable Formulations

[0154] Powdered DBOX (2.00 g, 9.51 mmol) and silica filler FL1966 (10.0 g) were dispersed in F-DGE (8.00 g, 25.6 mmol, amount of epoxy groups = 51.2 mmol), tetraphenylethylene glycol (25 mg ) and HD7980 (diaryliodonium hexafluorophosphate, 50mg) in a mixture. The resulting heterogeneous formulation was cured under the same conditions as used in Example 1-1.

[0155]

[0156] Curing reaction and shrinkage test were performed in the same manner as in Example 1-1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com