Fresh tea caffeine removing device

A caffeine and fresh tea technology, applied in tea, food science, application, etc., can solve the problems of integrated clean continuous production, difficult process, etc., to achieve clean production, reduce intermediate links, and reduce caffeine content Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

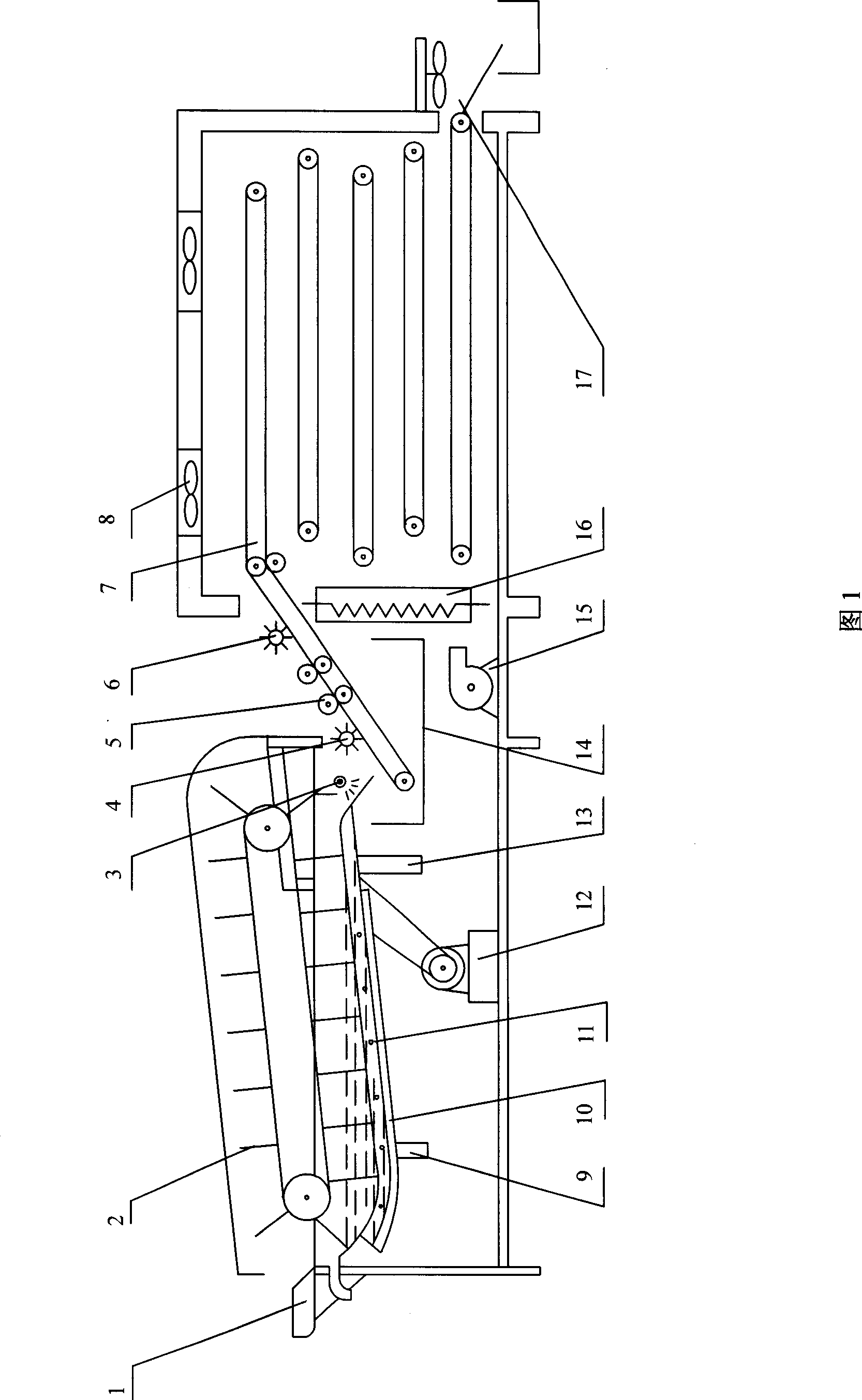

[0008] In the accompanying drawing 1, fresh tea is fed from the feeding port 1, and driven by the scraper 2, the tea leaves are pressed into the water and transported forward, and the decaffeinated tea leaves are sprayed and cooled by the spray device 3 Slide down to the conveyor belt 7, the homogenizer 4 evenly spreads the tea leaves on the conveyor belt 7, and uses the roll 5 to squeeze and absorb most of the surface water in the tea leaves. Under the action of 6, it enters the hot air belt type drying box for dehydration and drying, and cools and discharges the material at the discharge port 17.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com